Catalyst used for catalytic reforming of methanol and steam to produce hydrogen, and preparation method and application thereof

A catalytic reforming and catalyst technology, applied in the field of catalysis, can solve problems such as poor selectivity, and achieve the effects of good stability, high activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

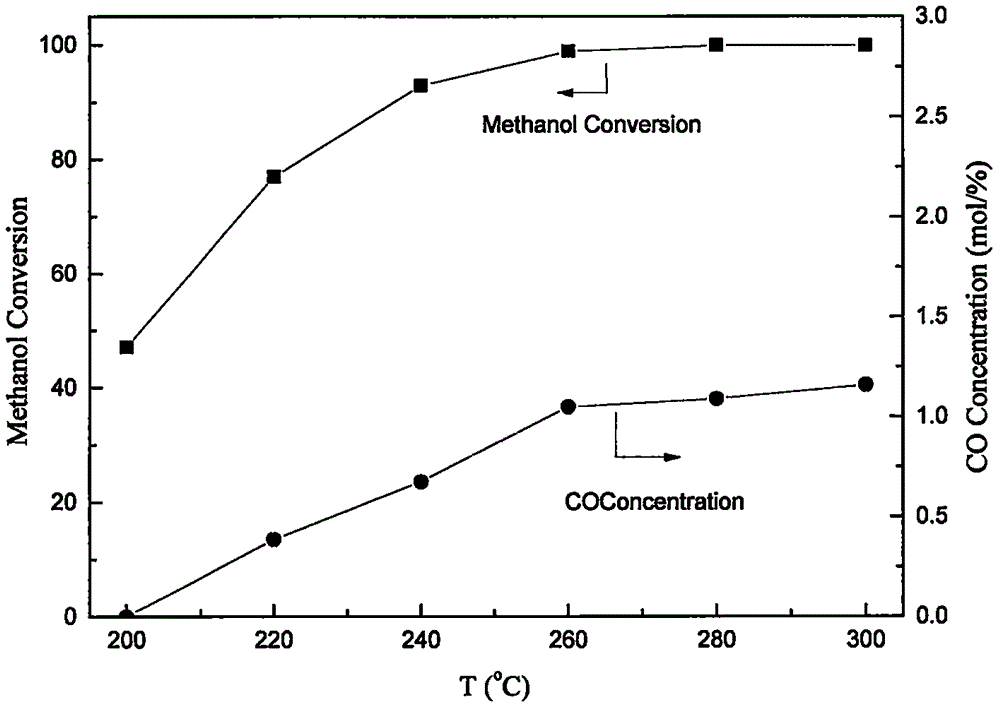

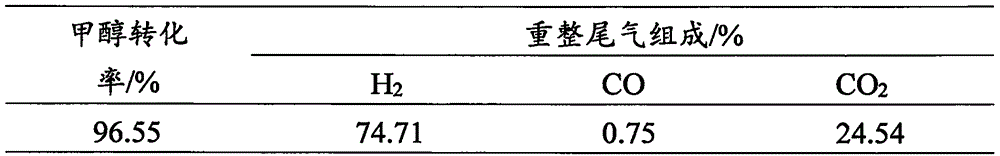

Examples

Embodiment 1

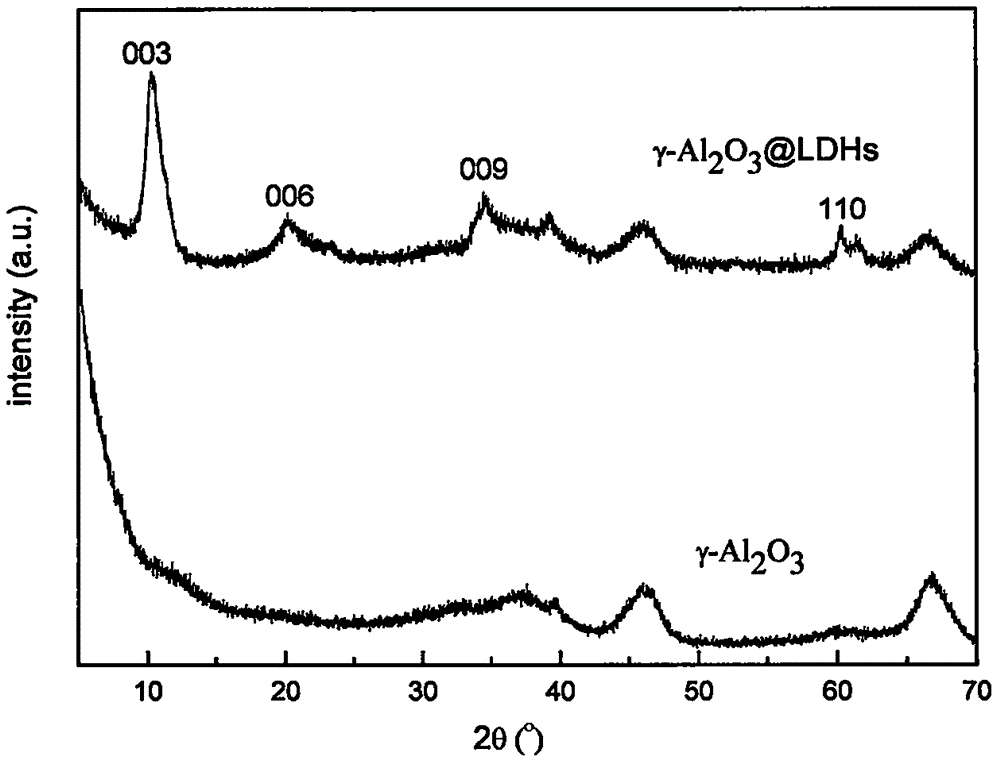

[0031] Catalyst 1: 5.89% CuO / 18.76% ZnO / γ-Al 2 o 3

[0032] Its preparation steps are as follows:

[0033] 1) First weigh 12g γ-Al 2 o 3 Calcined at 600°C for 4h in a muffle furnace; then weighed 4.5495g Zn(NO 3 ) 2 ·6H 2 O, 1.2242g NH 4 NO 3 , the two were mixed and dissolved in deionized water to form a nitrate solution with a concentration of 0.2mol / L, and then 5g of γ-Al was added 2 o 3 , mixed uniformly to form a mixed solution;

[0034] 2) Prepare 500mL of ammonia water with a mass fraction of 2%; under normal temperature stirring, drop the prepared 2% ammonia water into the prepared mixed solution; when the pH of the solution=8, stop adding ammonia water, and the temperature rises Measure the pH of the solution after continuing to stir at 50°C for 24 hours;

[0035] 3) Prepare ammonia water and NH that are the same as the above pH respectively 4 NO 3 , mixed to form a mixed washing solution for subsequent use;

[0036] 4) Suction filtration is performed o...

Embodiment 2

[0044] Catalyst 2: 5.89% CuO / 18.76% ZnO / γ-Al 2 o 3

[0045] Its preparation steps are as follows:

[0046] 1) First weigh 12g γ-Al 2 o 3 Calcined at 600°C for 4h in a muffle furnace; then weighed 4.5495g Zn(NO 3 ) 2 ·6H 2 O, 1.2242g NH 4 NO 3 , the two were mixed and dissolved in deionized water to form a nitrate solution with a concentration of 0.1mol / L, and then 5g of γ-Al was added 2 o 3 , mixed uniformly to form a mixed solution;

[0047] 2) Prepare 500mL of ammonia water with a mass fraction of 5%; under normal temperature stirring, drip the prepared 5% ammonia water into the prepared mixed solution; when the pH of the solution=8, stop dripping ammonia water, and the temperature rises Measure the pH of the solution after continuing to stir at 50°C for 24 hours;

[0048] 3) Prepare ammonia water and NH that are the same as the above pH respectively 4 NO 3 , mixed to form a mixed washing solution for subsequent use;

[0049] 4) Suction filtration is performed...

Embodiment 3

[0056] Catalyst: 3: 11.13% CuO / 17.71% ZnO / γ-Al 2 o 3

[0057] Its preparation steps are as follows:

[0058] 1) First weigh 12g γ-Al 2 o 3 Roasted in a muffle furnace at 600°C for 4h; then weighed 4.5495g Zn(NO 3 ) 2 ·6H 2 O, 1.2242g NH 4 NO 3 , the two were mixed and dissolved in deionized water to form a nitrate solution with a concentration of 0.05mol / L, and then 5g of γ-Al was added 2 o 3 , mixed uniformly to form a mixed solution;

[0059] 2) Prepare 500mL of ammonia water with a mass fraction of 2%; under normal temperature stirring, drop the prepared 2% ammonia water into the prepared mixed solution; when the pH of the solution=8, stop adding ammonia water, and the temperature rises Measure the pH of the solution after continuing to stir at 50°C for 24 hours;

[0060] 3) Prepare ammonia water and NH that are the same as the above pH respectively 4 NO 3 , mixed to form a mixed washing solution for subsequent use;

[0061]4) Suction filtration is performed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com