Method for preparing titanium dioxide/stannic oxide compounded oxide superfine nano particles

A composite oxide and tin dioxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of large particle size, cumbersome, time-consuming technology, etc. problems, to achieve the effect of easy operation control, low preparation cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

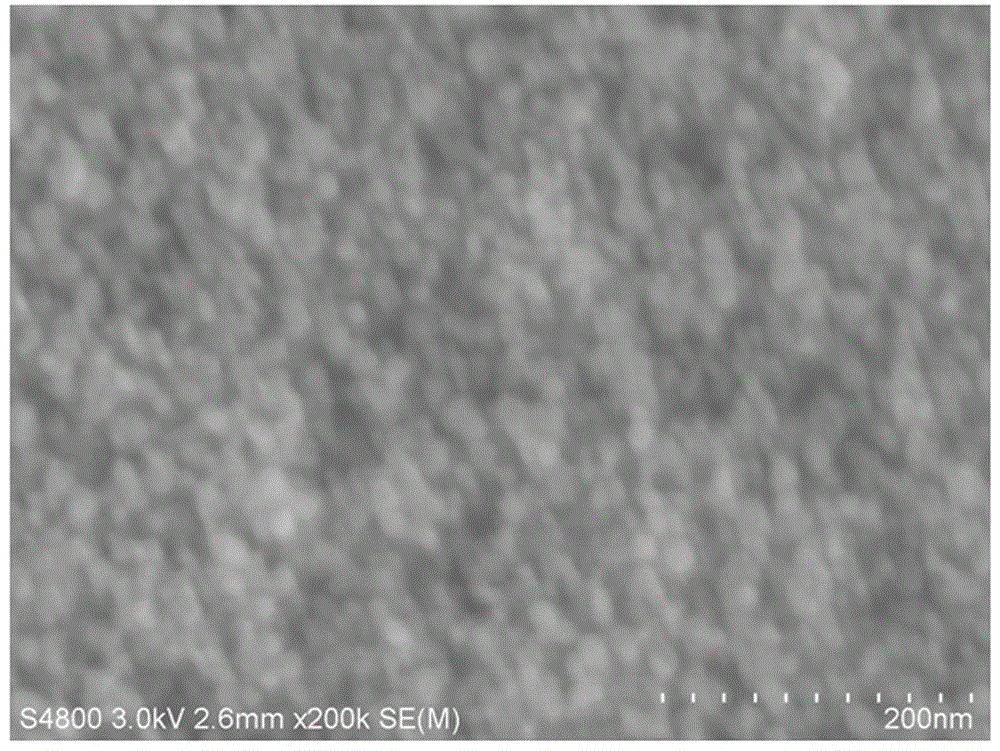

[0031] Example 1.

[0032] Tetrabutyl titanate, tin tetrachloride and oxalic acid are prepared into an aqueous solution, wherein the molar ratio of tetrabutyl titanate, tin tetrachloride and oxalic acid is 1:1:20. The molar concentration of tetrabutyl titanate is 0.05 mol / L, and the molar concentration of oxalic acid is 1.0 mol / L. The heating temperature is 100 °C, and the stirring speed is 60 rpm. After evaporation to dryness, the cross-linking reaction is carried out. The reaction temperature is 200 °C and the reaction time is 2 hours. After the cross-linking reaction is completed, the high-temperature reaction is continued in a muffle furnace. The high-temperature reaction temperature is 600 °C and the reaction time is 4 h. After natural cooling, the target product is obtained. The particle size of the product is between 10 and 12 nm, the band gap is 2.9 eV, and the yield of the product is 99.7%. Product purity is 99.9%, impurity content: carbon is less than 0.1%.

[0033] ...

Example Embodiment

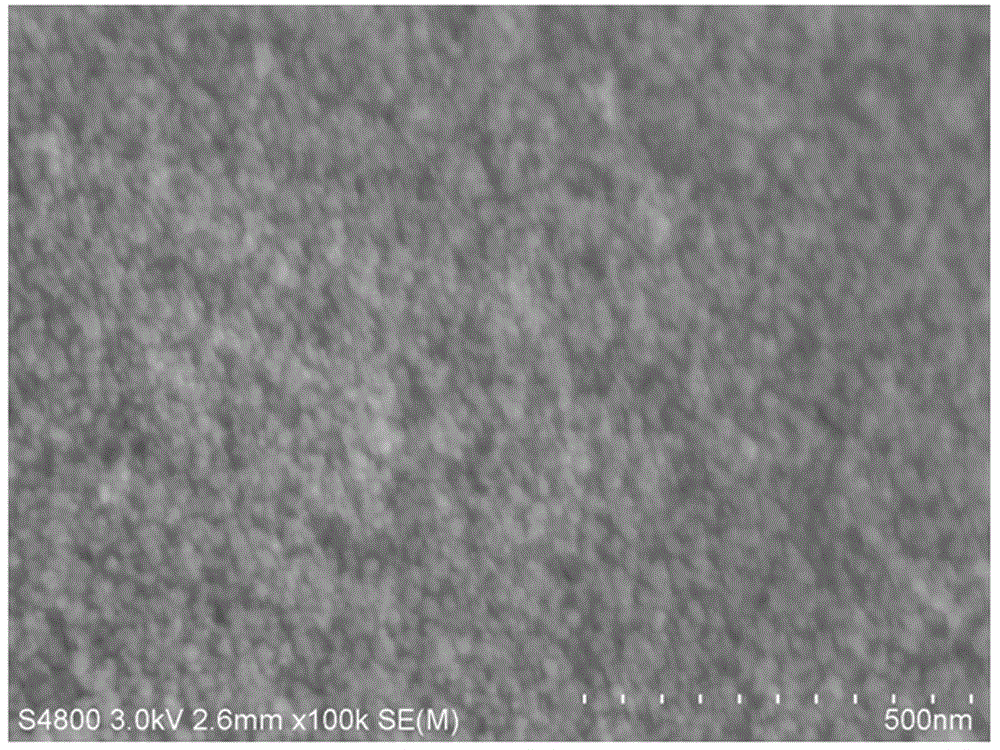

[0034] Example 2.

[0035] Tetrabutyl titanate, tin tetrachloride and oxalic acid are prepared into an aqueous solution, wherein the molar ratio of tetrabutyl titanate, tin tetrachloride and oxalic acid is 1:1:10. The molar concentration of tetrabutyl titanate is 0.01 mol / L, and the molar concentration of oxalic acid is 0.1 mol / L. The heating temperature is 100 °C, and the stirring speed is 60 rpm. After evaporation to dryness, the cross-linking reaction is carried out. The reaction temperature is 200 °C and the reaction time is 2 hours. After the cross-linking reaction is completed, the high-temperature reaction is continued in a muffle furnace. The high-temperature reaction temperature is 600 °C and the reaction time is 4 h. After natural cooling, the target product is obtained. The product particle size is between 15-20nm, the band gap is 3.0eV, and the product yield is 99.6%. Product purity 99.7%, impurity content: carbon less than 0.3%.

[0036] The prepared ultrafine nan...

Example Embodiment

[0037] Example 3.

[0038] Tetrabutyl titanate, tin tetrachloride and oxalic acid are prepared into an aqueous solution, wherein the molar ratio of tetrabutyl titanate, tin tetrachloride and oxalic acid is 1:1:20. The molar concentration of tetrabutyl titanate is 0.05 mol / L, and the molar concentration of oxalic acid is 1.0 mol / L. The heating temperature is 100 °C, and the stirring speed is 60 rpm. After evaporation to dryness, the cross-linking reaction is carried out. The reaction temperature is 200 °C and the reaction time is 2 hours. After the cross-linking reaction is completed, the high-temperature reaction is continued in a muffle furnace. The high-temperature reaction temperature is 500 °C and the reaction time is 8 h. After natural cooling, the target product is obtained. The product particle size is between 15-18nm, the band gap is 2.95eV, and the product yield is 99.0%. Product purity 99.7%, impurity content: carbon less than 0.3%.

[0039] The prepared ultrafine na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com