Healthy electronic cigarette cotton

A tobacco cotton, healthy technology, applied in the field of electronic cigarettes, to achieve the effect of good taste, low cost, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

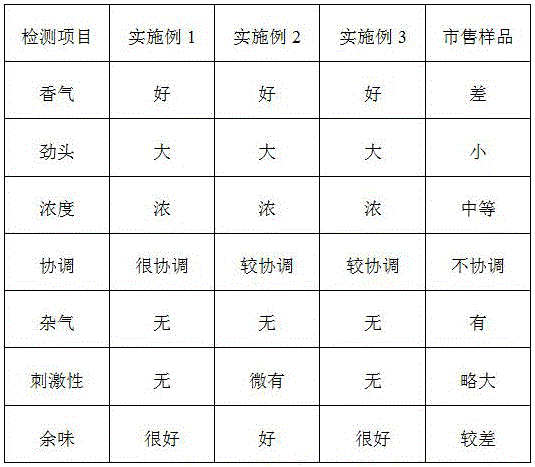

Examples

Embodiment 1

[0021] A healthy electronic cigarette cotton, comprising the following components by weight percentage:

[0022] Tobacco stem fiber 45%, tobacco dust fiber 35%, calcined shell powder 20%.

[0023] The particle size of the calcined shell powder is 20-50 μm.

[0024] The preparation method of described calcined shell powder comprises the following steps:

[0025] A. After washing and crushing the shells, soak them in 10% sodium hydroxide solution for 8.5 hours;

[0026] B. Rinse the soaked shells with water to neutrality and dry;

[0027] C. Calcining the dried shells in a muffle furnace at 820° C., maintaining the temperature for 7 hours, grinding the calcined products, and sieving to obtain calcined shell powder.

Embodiment 2

[0029] A healthy electronic cigarette cotton, comprising the following components by weight percentage:

[0030] Tobacco stem fiber 55%, tobacco dust fiber 30%, calcined shell powder 15%.

[0031] The particle size of the calcined shell powder is 20-50 μm.

[0032] The preparation method of described calcined shell powder comprises the following steps:

[0033] A. After washing and crushing the shells, soak them in 10% sodium hydroxide solution for 8 hours;

[0034] B. Rinse the soaked shells with water to neutrality and dry;

[0035] C. Calcining the dried shells in a muffle furnace at 820° C., maintaining the temperature for 8 hours, grinding the calcined products, and sieving to obtain calcined shell powder.

Embodiment 3

[0037] A healthy electronic cigarette cotton, comprising the following components by weight percentage:

[0038] Tobacco stem fiber 40%, tobacco dust fiber 40%, calcined shell powder 20%.

[0039] The particle size of the calcined shell powder is 20-50 μm.

[0040] The preparation method of described calcined shell powder comprises the following steps:

[0041] A. After washing and crushing the shells, soak them in 10% sodium hydroxide solution for 10 hours;

[0042] B. Rinse the soaked shells with water to neutrality and dry;

[0043] C. Calcining the dried shells in a muffle furnace at 820° C., maintaining the temperature for 6 hours, grinding the calcined products, and sieving to obtain calcined shell powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com