Low-sugar regenerated rice production process and product thereof

A production process, the technology of regenerated rice, applied in the field of food processing, can solve the problems of rapid blood sugar rise, low utilization rate of rice processing by-products, waste of food, etc., and achieve the effect of improving utilization, reducing waste and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

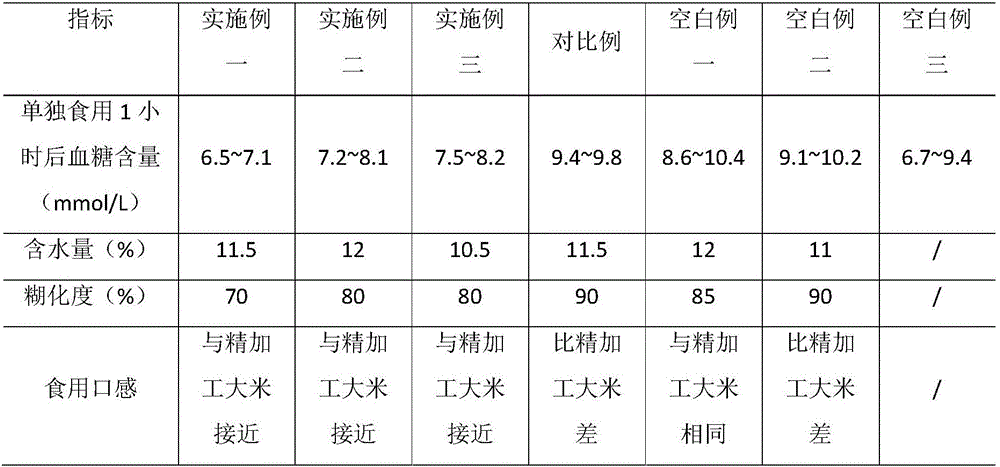

Examples

Embodiment 1

[0015] Embodiment 1. In this embodiment, each part of the raw material is pulverized separately, the rice bran powder is passed through a 120-mesh sieve, and the rest of the raw materials are passed through a 80-mesh sieve for later use. Wherein the ingredients of each raw material are respectively by weight fraction: broken rice powder 36, rice bran powder 5, coarse powder 7, bitter gourd powder 20, yam powder 7, lotus seed powder 9, barley powder 8, taro powder 8. Put the raw materials into the mixer, add water at a temperature of 42°C for stirring and tempering, and adjust to a final moisture content of 20%; send the tempered raw materials into a twin-screw extruder for extrusion granulation, and the feeding section of the extruder and The temperature of the metering section is controlled at 55° C., the temperature of the compression section is controlled at 90° C., and the screw speed is controlled at 260 revolutions per minute. The extruded rice grain raw material is sent...

Embodiment 2

[0016] Embodiment 2. In this embodiment, each part of the raw material is pulverized separately, the rice bran powder is passed through a 120-mesh sieve, and the rest of the raw materials are passed through a 80-mesh sieve for use. Wherein the raw material components are respectively by weight fraction: 15 broken rice flour, 10 rice bran flour, 10 coarse flour, 23 bitter gourd flour, 8 yam flour, 12 lotus seed flour, 12 barley flour and 10 taro flour. Put the raw materials into the mixer, add water at a temperature of 45°C for stirring and tempering, and adjust to a final moisture content of 20%; send the tempered raw materials into a twin-screw extruder for extrusion granulation, and the feeding section of the extruder and The temperature of the metering section is controlled at 50°C, the temperature of the compression section is controlled at 85°C, and the screw speed is controlled at 240 rpm. The extruded rice grain raw material is sent to the two-stage gradient hot air dry...

Embodiment 3

[0017] Embodiment 3. In this embodiment, each part of the raw material is pulverized separately, the rice bran powder is passed through a 120-mesh sieve, and the rest of the raw materials are passed through a 80-mesh sieve for use. Wherein the ingredients of each raw material are respectively by weight fraction: broken rice powder 45, rice bran powder 5, coarse powder 5, bitter gourd powder 16, yam powder 5, lotus seed powder 8, barley powder 8, taro powder 8. Put the raw materials into the mixer, add water at a temperature of 40°C for stirring and tempering, and adjust to a final moisture content of 20%; send the tempered raw materials into a twin-screw extruder for extrusion granulation, and the feeding section of the extruder and The temperature of the metering section is controlled at 60° C., the temperature of the compression section is controlled at 90° C., and the screw speed is controlled at 270 revolutions per minute. The extruded rice grain raw material is sent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com