Decoration panel with concealed touch control display function, and preparation method thereof

A touch display and decorative panel technology, which is applied in the input/output process of data processing, instruments, electrical and digital data processing, etc. Impact strength, the effect of enhancing surface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

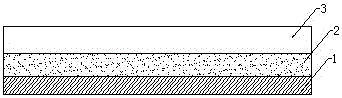

[0035] In this embodiment, the method for preparing a decorative panel with an invisible touch display function, the specific steps of the preparation method are as follows:

[0036] (1) Treat the glass with a thickness of 0.3mm through chemical strengthening, semi-tempered or fully tempered process to obtain a tempered glass panel with a thickness of 1.5mm;

[0037] (2) On the tempered glass panel, a decorative film with a thickness of 500µm and a light transmittance of 90% is added through a series of processes of silk screen printing, embossing, coating and transfer printing to form a high-transparency decorative film layer;

[0038] (3) On the high-transparency decorative film layer, vacuum coating is used to coat a layer of highly dense non-conductive film with high light transmittance and high color emission rate to form a high-density film with a thickness of 10nm and a light transmittance of 70%. Transparent and highly reflective non-conductive coating;

[0039] (4) O...

Embodiment 2

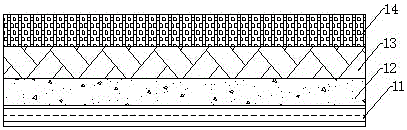

[0042] In this embodiment, the method for preparing a decorative panel with an invisible touch display function, the specific steps of the preparation method are as follows:

[0043] (1) Treat the glass with a thickness of 4.2mm through chemical strengthening, semi-tempered or full-tempered process to obtain a tempered glass panel with a thickness of 5.5mm;

[0044] (2) On the tempered glass panel, a decorative film with a thickness of 500µm and a light transmittance of 70% is added through a series of processes of silk screen printing, embossing, coating and transfer printing to form a high-transparency decorative film layer;

[0045] (3) On the high-transparency decorative film layer, vacuum coating is used to coat a layer of highly dense non-conductive film with high light transmittance and high color emission rate to form a high-density film with a thickness of 1000nm and a light transmittance of 10%. Transparent and highly reflective non-conductive coating;

[0046] (4) ...

Embodiment 3

[0049] In this embodiment, the method for preparing a decorative panel with an invisible touch display function, the specific steps of the preparation method are as follows:

[0050] (1) Treat the glass with a thickness of 4.3mm through chemical strengthening, semi-tempered or full-tempered process to obtain a tempered glass panel with a thickness of 5.5mm;

[0051] (2) On the tempered glass panel, a decorative film with a thickness of 500µm and a light transmittance of 55% is added through a series of processes of silk screen printing, embossing, coating and transfer printing to form a high-transparency decorative film layer;

[0052] (3) On the high-transparency decorative film layer, a non-conductive film with high density and high light transmittance and high color-emitting rate is coated by vacuum coating method to form a high-density film with a thickness of 455nm and a light transmittance of 40%. Transparent and highly reflective non-conductive coating;

[0053] (4) On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com