Method And Device For Adjusting The Amplitudes Of Oscillation Of Swing Fire Installations For Material Treatment Or Synthesis

A technology of oscillating combustion and burner, which is applied in combustion methods, gas fuel burners, burners, etc., and can solve problems such as incomparability of material properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

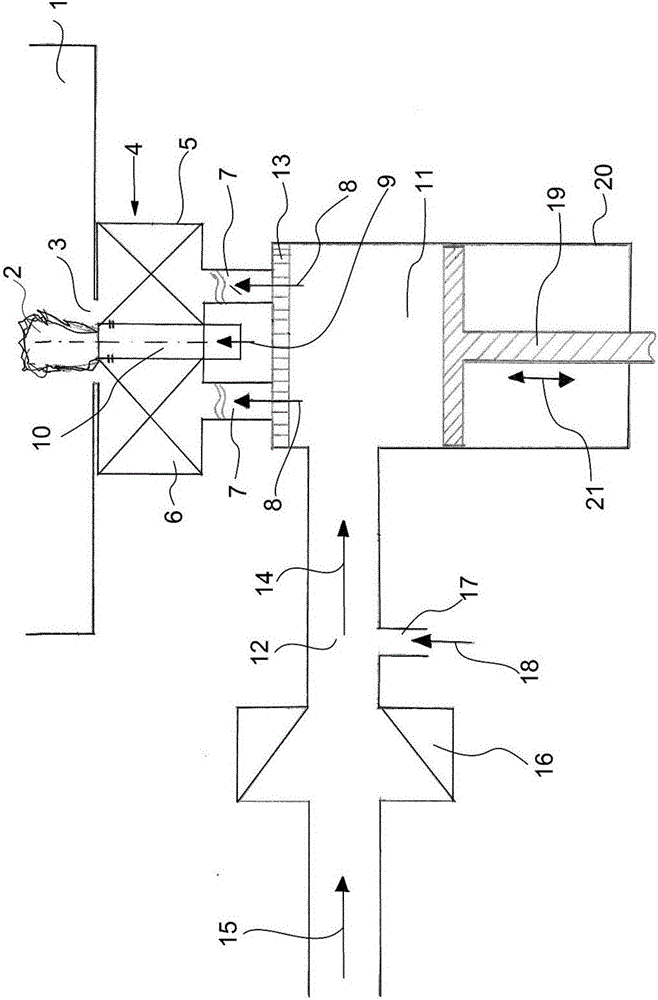

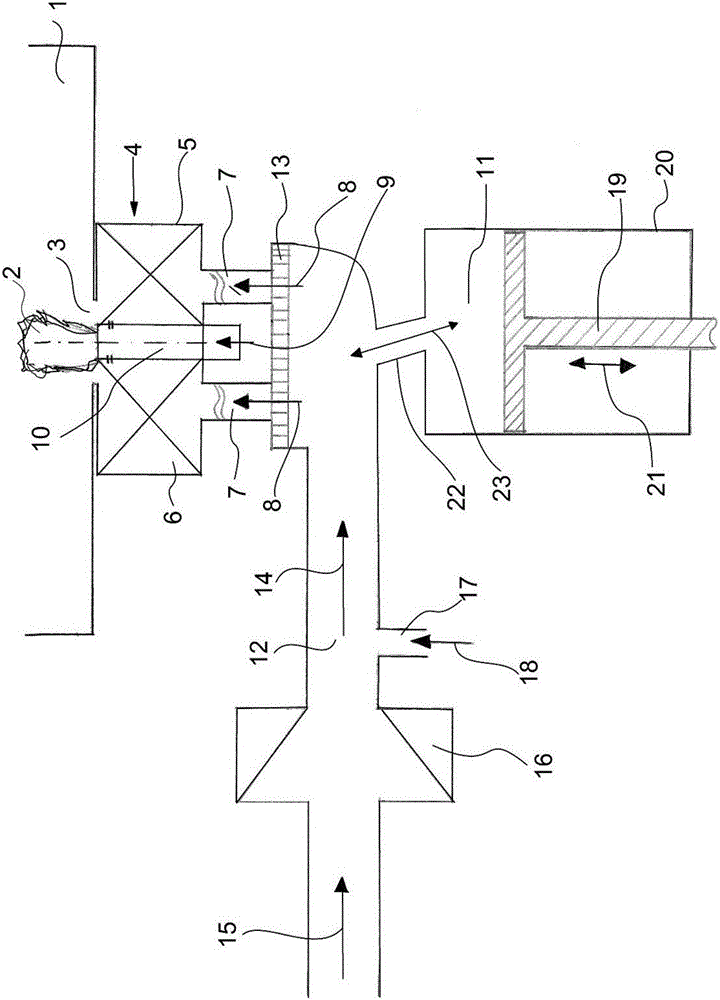

[0059] exist figure 1 A schematic diagram of the device according to the invention is shown in .

[0060] The combustion chamber 1 can be seen, into which the flame 2 is directed.

[0061] The flame 2 is generated at the burner outlet 3 of the burner 4 . In this case, the section of the system which is fluidly situated upstream of the burner outlet is considered to be the cold side of the burner.

[0062] The flame 2 pulsates and thus causes a system-specific resonant gas column pulsation in the combustion chamber and / or in a reaction chamber downstream of this combustion chamber. The educts are fed into this combustion chamber or reaction chamber, processed in an oscillating gas column from the hot gas, and finally the products thus produced are removed from the hot gas stream, for example by means of a hot gas filter, cyclone separator or the like.

[0063] Flame 2 pulsation is a self-excited combustion instability, where the frequency of its self-excited oscillations is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com