Metal shell, manufacturing method and mobile terminal

A technology of metal shell and metallic luster, which is applied in metal shell, telephone structure, telephone communication, etc., can solve the problems affecting the ability of the antenna to transmit and receive communication signals, etc., so as to enhance the metal feeling and aesthetic appearance of the whole machine, The effect of reducing the process flow and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

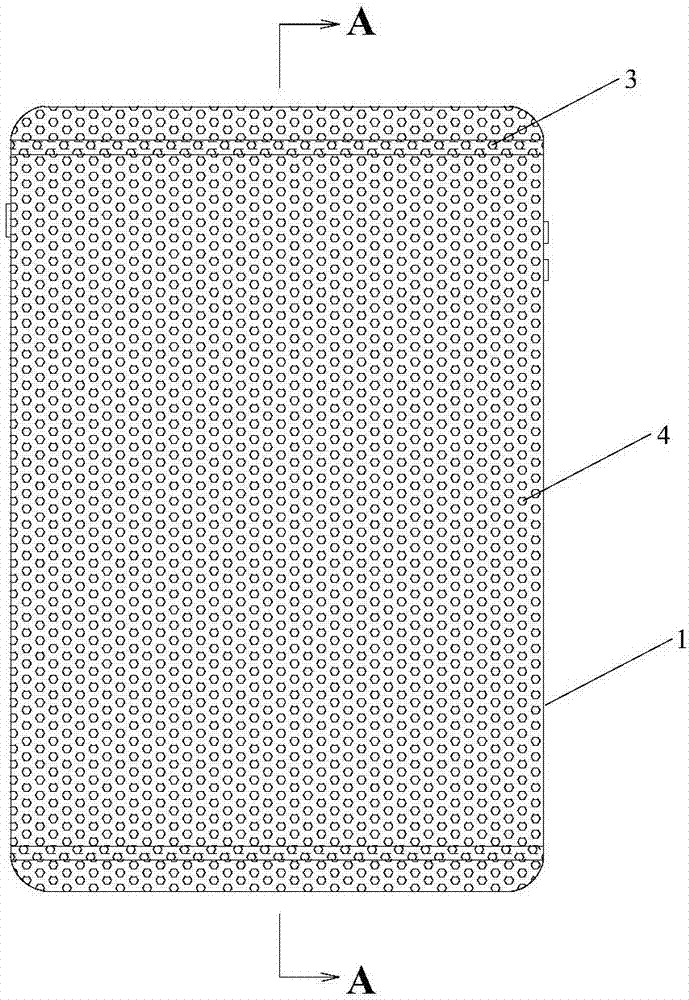

[0018] Figure 1a A schematic diagram of the metal casing in Embodiment 1 of the present invention is shown. Such as Figure 1a As shown, there is a gap on the metal shell 1; the gap is filled with an insulator 3, and the insulator 3 includes a plastic material, a first pigment and a second pigment, wherein the first pigment is used for the plastic material Coloring, so that the insulator 3 presents the same color as the finished metal shell (the color layer 4 can be formed in the area of the metal shell without gaps through a surface treatment process, thereby obtaining the finished metal shell), and the second pigment is used In order to change the luster of the plastic material, the insulator 3 has the same metallic luster as the finished metal shell.

[0019] The mass percentage of the first pigment in the insulator 3 is 0.1%-0.5%, the mass percentage of the second pigment is 0.1%-1%, and the rest is plastic material. The plastic material includes polyphenylene sulfide ...

Embodiment 2

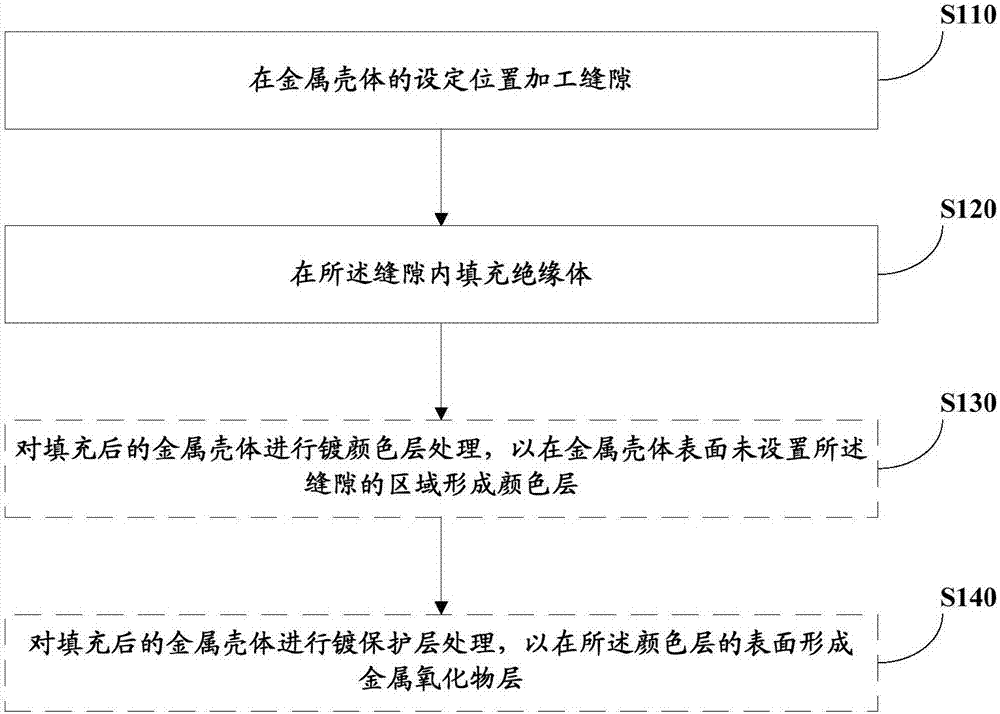

[0027] Figure 2a A flow chart of the manufacturing method of the metal shell in the second embodiment of the present invention is shown. This method is applicable to the situation of preparing the metal shell in the above-mentioned embodiment, such as Figure 2a As shown, the manufacturing method of the metal shell comprises the following steps:

[0028] Step 110, machining gaps at the set positions of the metal shell.

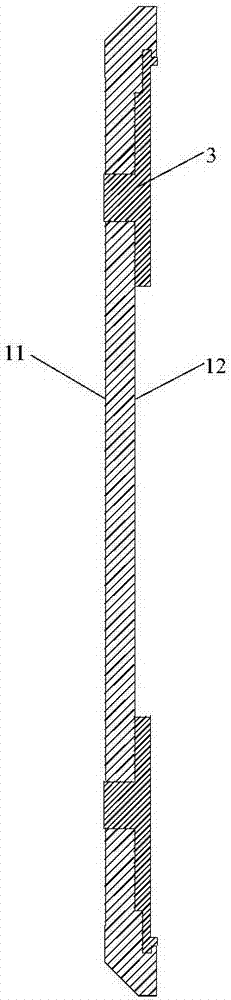

[0029] Figure 2b It shows a schematic diagram of the metal shell processed with gaps in the manufacturing method of the metal shell provided in the second embodiment of the invention. Such as Figure 2b As shown, taking the back shell of a smart phone as an example, a through channel extending from the first surface of the back shell to the second surface is respectively opened at the top and bottom of the metal shell 1 as the gap 2, thereby destroying the metal shell 1. The closure of the housing 1.

[0030] Optionally, a slit can also be provided at ...

Embodiment 3

[0054] This embodiment provides a mobile terminal, which includes the metal casing as described in the above embodiments, and components for supporting the normal operation of the mobile terminal. Exemplarily, the mobile terminal in this embodiment may specifically be a terminal such as a mobile phone, a tablet computer, and a digital reader, preferably a smart phone. The metal casing may be the rear casing or the middle frame of the mobile terminal. The metal shell is prepared by the manufacturing method of the metal shell provided in Example 2, so that the insulator filled in the gap has the same color and luster as the finished metal shell, visually presents a seamless appearance effect, and solves the problem of the current antenna The problem of inconsistency between the appearance of the partition strip and the metal shell saves the step of spraying the paint layer on the antenna partition strip, achieving the effects of reducing the process flow, improving production ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com