A processing fixture and processing method for realizing aluminum-nickel bonding of ceramic chip packaging devices

A patch packaging and processing method technology, which is applied in the manufacture of semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve problems such as inability to achieve quantitative uniformity, affect device quality, and affect bonding strength. Clamping and alignment time, ensuring appearance quality, and avoiding assembly difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

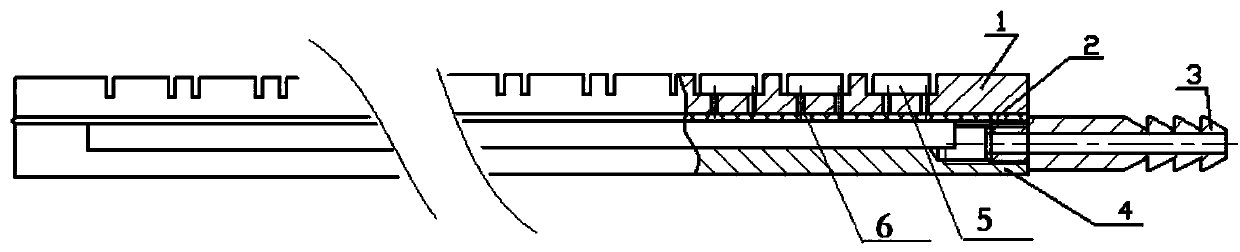

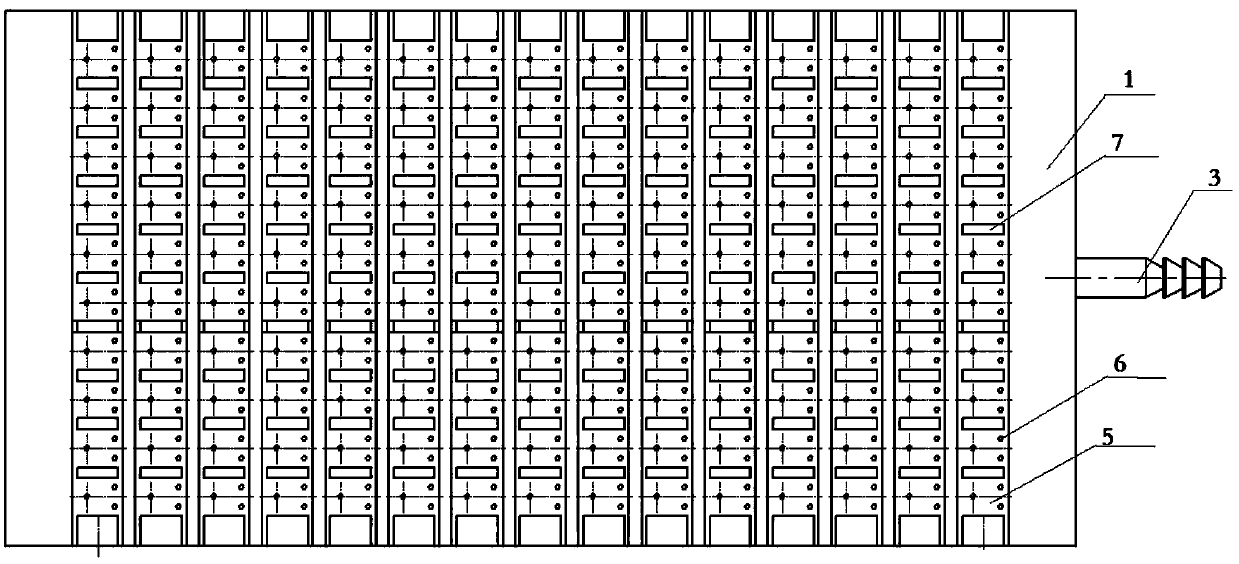

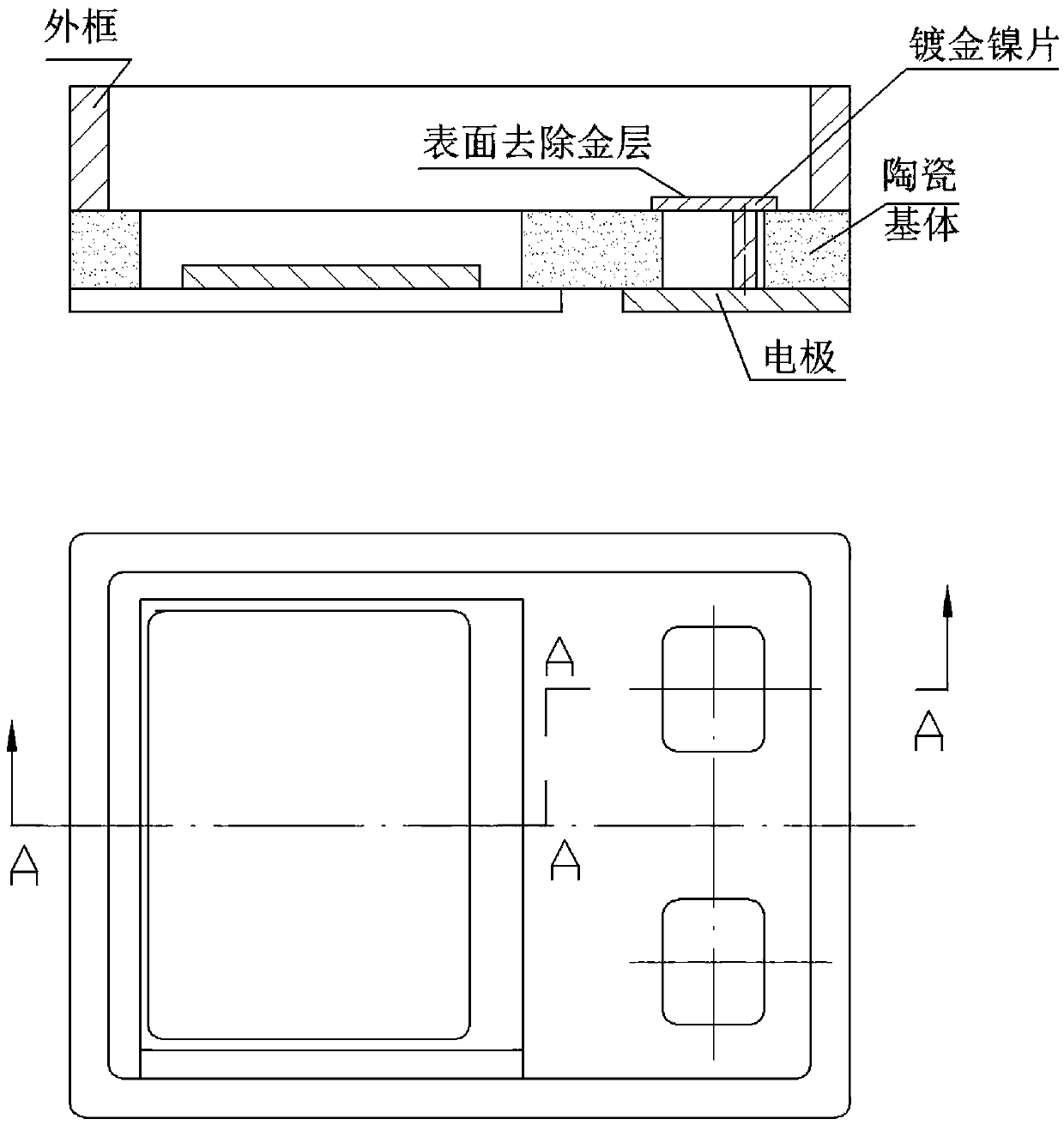

[0029] A processing fixture for realizing aluminum-nickel bonding of ceramic chip packaged devices; including a base plate 4, the base plate 4 is provided with a large-area groove in the middle of the upper end, and an air nozzle 3 is installed on one side of the base plate 4, and the air nozzle 3 is connected to the In the groove on the bottom plate 4, a rubber pad 2 is installed on the upper end of the bottom plate 4, and a plurality of cavities 5 are arranged on the upper end of the positioning plate 1, and each cavity 5 is separated by a partition 7, and the cavities There are three air holes 6 through which the positioning plate 1 is penetrated in the vertical direction.

[0030] The shape, size and area of the end faces of the positioning plate 1, the rubber pad 2 and the bottom plate 4 are all the same.

[0031] The rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com