Electric wire applied in transformer substation

A technology for substations and electric wires, applied in the direction of power cables, circuits, insulated cables, etc., can solve problems such as electric shock accidents, power transportation losses, etc., and achieve a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

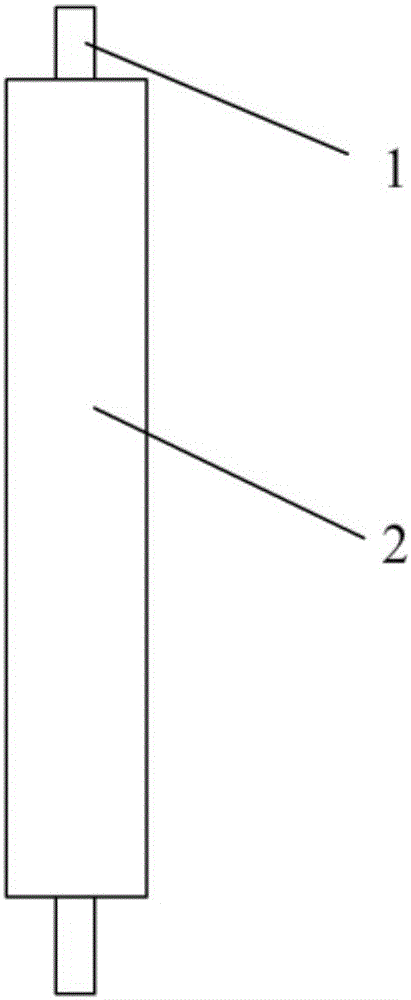

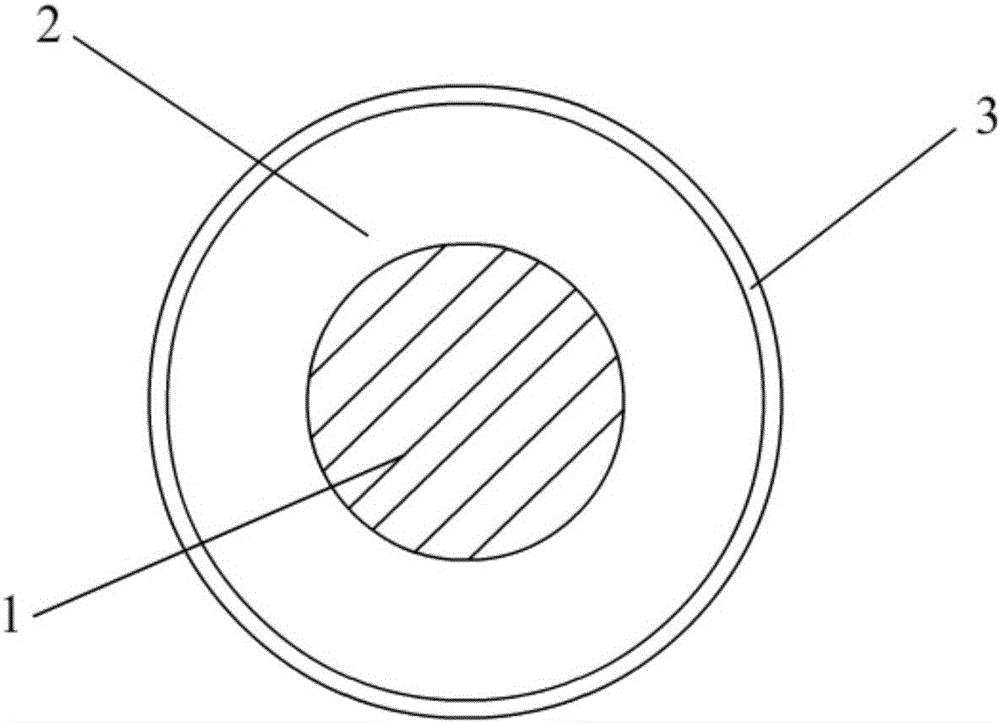

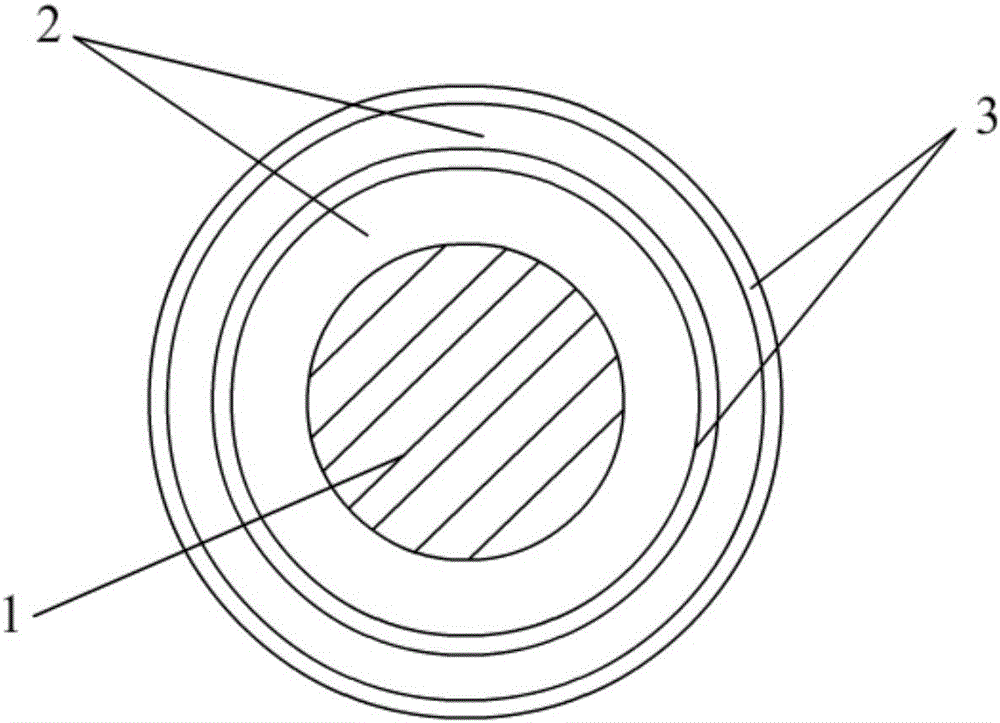

Image

Examples

Embodiment 1

[0034] A coating liquid applied to electric wires in substations, characterized in that it comprises the following plant tissue raw materials in parts by weight:

[0035] There are 32 parts of the leaves of Boswellia chinensis, 61 parts of the leaves of Arrowroot, and 54 parts of the petals of Hexagonal chrysanthemum.

[0036] A method for preparing a coating liquid applied to electric wires in substations, characterized in that it comprises the following steps:

[0037] (1) Choose 32 parts by weight of fresh Leuvengrass leaves, 61 parts by weight of arrowroot leaves, and 54 parts by weight of chrysanthemum pterygium petals, and soak them in clear water for 7 hours. The added clear water is as follows: standard;

[0038] (2) Take the plant material out of the clean water, put it in the freezer and freeze it at a temperature between -20°C and -30°C for 24 hours;

[0039] (3) Take out the plant material from the refrigerator and add 100 parts by weight of water, put it into a ...

Embodiment 2

[0045] A coating liquid applied to electric wires in substations, characterized in that it comprises the following plant tissue raw materials in parts by weight:

[0046] There are 55 parts of the leaves of Boswellia chinensis, 80 parts of the leaves of Arrowroot, and 75 parts of the petals of Hexaphyllum pterygium.

[0047] A method for preparing a coating liquid applied to electric wires in substations, characterized in that it comprises the following steps:

[0048](1) Choose 55 parts by weight of fresh Leucophyllum fragrans leaves, 80 parts by weight of arrowroot leaves, and 75 parts by weight of chrysanthemum pterygium petals, and soak them in clear water for 7 hours. standard;

[0049] (2) Take the plant material out of the clean water, put it in the freezer and freeze it at a temperature between -20°C and -30°C for 48 hours;

[0050] (3) Take out the plant material from the refrigerator and add 150 parts by weight of water, put it into a blender and stir for 5 minutes...

Embodiment 3

[0056] A coating liquid applied to electric wires in substations, characterized in that it comprises the following plant tissue raw materials in parts by weight:

[0057] Thirty-five parts of the leaves of Boswellia chinensis, 69 parts of leaves of Arrowroot Arrowroot, and 60 parts of petals of Hexagonal chrysanthemum.

[0058] A method for preparing a coating liquid applied to electric wires in substations, characterized in that it comprises the following steps:

[0059] (1) Choose 35 parts by weight of fresh Leucophyllum fragrans leaves, 69 parts by weight of arrowroot leaves, and 60 parts by weight of chrysanthemum chrysanthemum petals, and soak them in clear water for 7 hours. standard;

[0060] (2) Take the plant material out of the clean water, put it into the freezer and freeze it at a temperature between -20°C and -30°C for 40 hours;

[0061] (3) Take out the plant material from the refrigerator and add 120 parts by weight of water, put it into a blender and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com