Detection tool for distinguishing different standards of flanges and detection method thereof

A technology of inspection fixtures and flanges, which is applied in the field of inspection fixtures to distinguish flanges of different standards, can solve problems such as low measurement accuracy and efficiency, inability to penetrate bolts, uneven outer diameters, etc., to improve batch detection efficiency and rapid detection , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

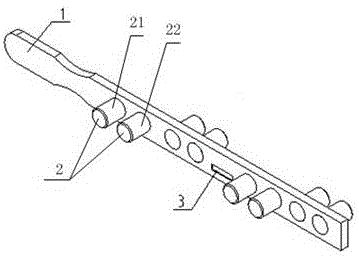

[0019] Embodiment one, as figure 1 As shown, the present invention is specifically a kind of inspection tool for distinguishing different standard flanges. Each detection surface is provided with two inner detection pins 22 and two outer detection pins 21, the outer detection pins are located at the periphery of the inner detection pins, and the distance between each adjacent inner and outer detection pins is the same, each There is also a marking mark on the first detection surface. The four test pins on each test surface of the test fixture body 1 match the relevant dimensions of the standard specification flange, that is, a point on the surface of the test fixture body 1 is used as a symmetrical reference, and the nominal size of the center-to-center distance between the two inner test pins on this surface is equal to that of the standard method. The nominal dimension of the diameter of the center circle of the threaded hole of the flange, the nominal dimension of the cent...

Embodiment 2

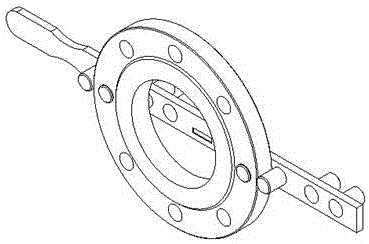

[0021] Embodiment two, such as figure 2 As shown, if the external dimensions of the inspection tool body 1 are reasonably designed, one inspection surface can be added, and three inspection surfaces can be set.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com