Corrugated fin heat exchange structure for mine air cooler and design method of corrugated fin heat exchange structure

A technology of corrugated fins and heat exchange structure, which is applied in the field of heat exchange, can solve the problems of large volume of heat exchange equipment, difficult to use, easy to accumulate dust and scale, etc., and achieve low investment cost, reasonable structure design, and simple processing and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

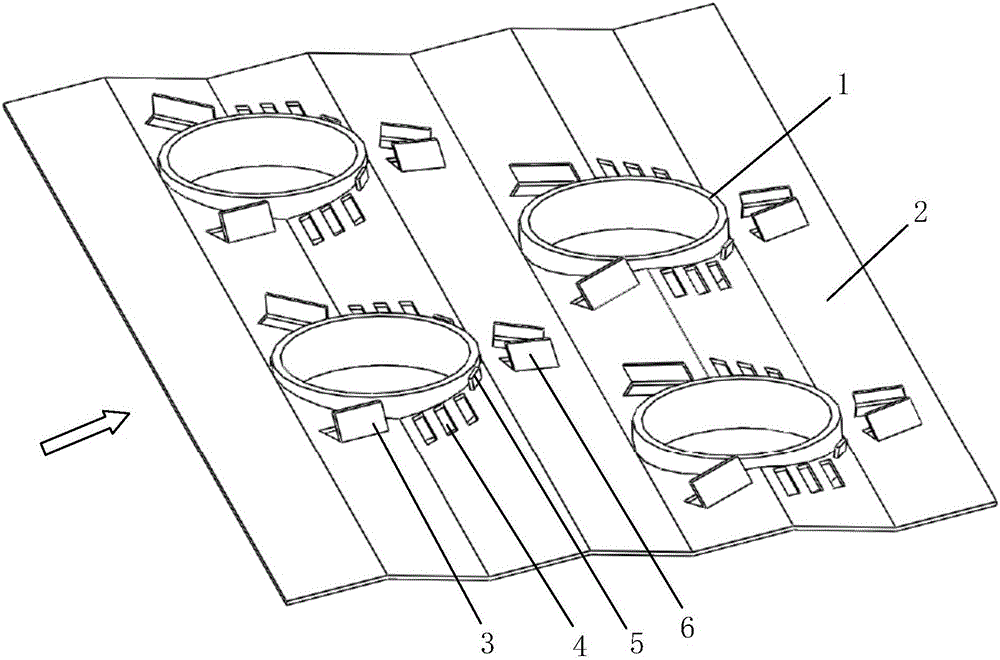

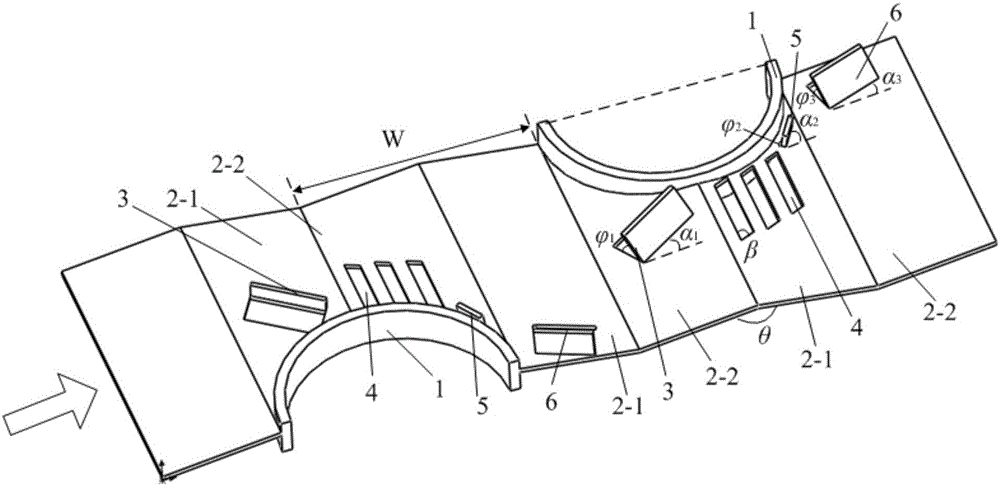

[0042] Such as figure 1 , figure 2 The shown corrugated fin heat exchange structure for the mine air cooler includes multiple rows of heat exchange tubes 1 and corrugated fins 2 installed on the multiple rows of heat exchange tubes 1, and the corrugated fins 2 are zigzag corrugated plates; Multiple rows of heat exchange tubes 1 are evenly arranged, and each row of heat exchange tubes 1 includes a plurality of heat exchange tubes 1 arranged from front to back along the length direction of the corrugated fins 2, and the plurality of heat exchange tubes 1 are all arranged on the same straight line, the structure and size of the plurality of heat exchange tubes 1 are the same and they are evenly arranged; the heat exchange tubes 1 in two adjacent rows of heat exchange tubes 1 are arranged in a staggered manner; The corrugated fins 2 are composed of a plurality of corrugated fin units arranged from back to front along the flow direction of the airflow. The structure and size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com