Light distributing mirror of anti-fog automobile lamp and anti-fog automobile lamp

A technology for automotive lights and light distribution mirrors, applied in electric light sources, motor vehicles, road vehicles, etc., can solve the problem of affecting the appearance and optical effect of the lights, the flow of anti-fog coatings, and the inability to maintain the anti-fogging effect for a long time. The problem is to avoid fogging of the light distribution mirror and solve the fogging of the headlights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

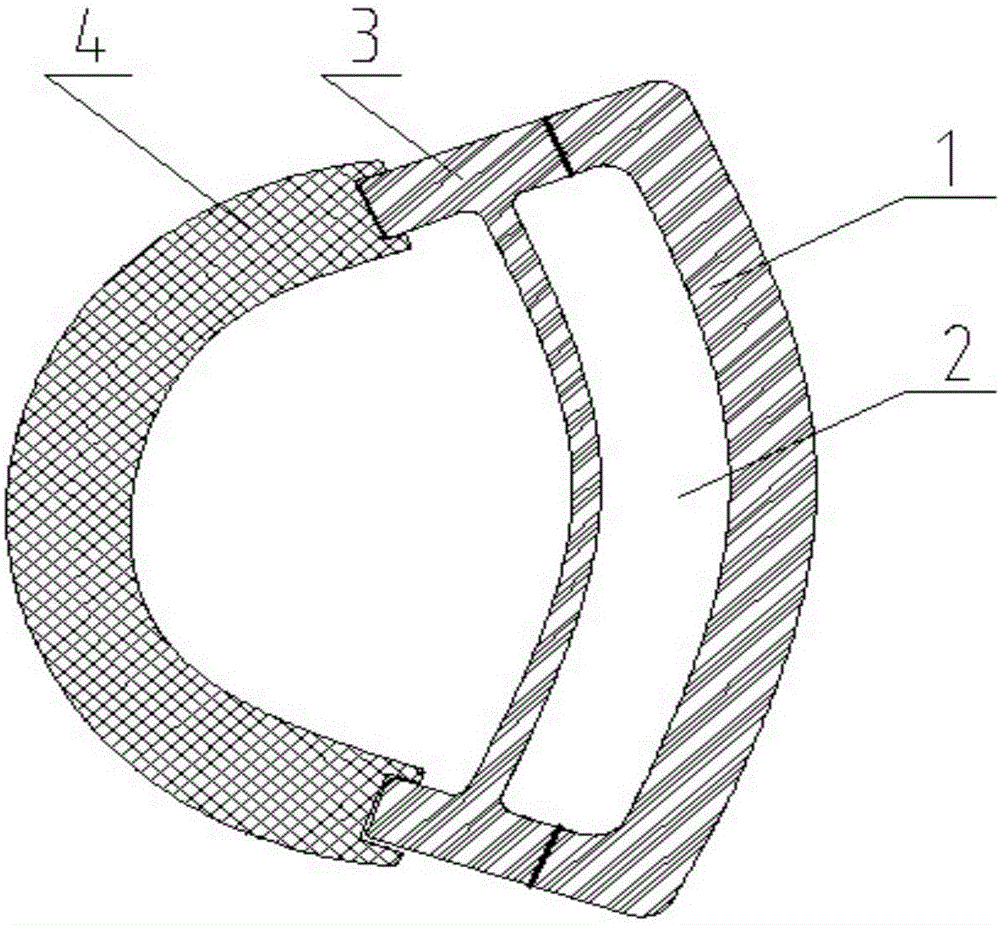

[0021] The invention discloses an anti-fogging light distribution mirror for automobile lamps (which may be referred to as a light distribution mirror for short), which is provided with at least two layers of lenses, and the gap between the adjacent two layers of lenses is in a sealed vacuum state. Each layer of lens is the exterior part of the car lamp or a part thereof capable of transmitting light.

[0022] Most of the fogging phenomenon is caused by the temperature difference between the inside and outside of the lamp. Specifically, the temperature on the light distribution mirror of the lamp is lower than the dew point of the humid air in the lamp cavity, so the moisture condensation occurs on the inner surface of the light distribution mirror. The anti-fogging automotive light distribution mirror of the present invention is used to form a theoretical heat insulating layer by setting a vacuum closed gap between two adjacent layers of the optical distribution mirror lens, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com