Integrated sealing axle box bearing for locomotive axle box

An axle box bearing, an integral technology, applied in the direction of shafts and bearings, bearing components, roller bearings, etc., can solve the problems of damaged raceway surface quality, bearing raceway fatigue failure, bearing raceway uneven force, etc., to achieve Reduce contact stress, improve the effect of compact structure and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

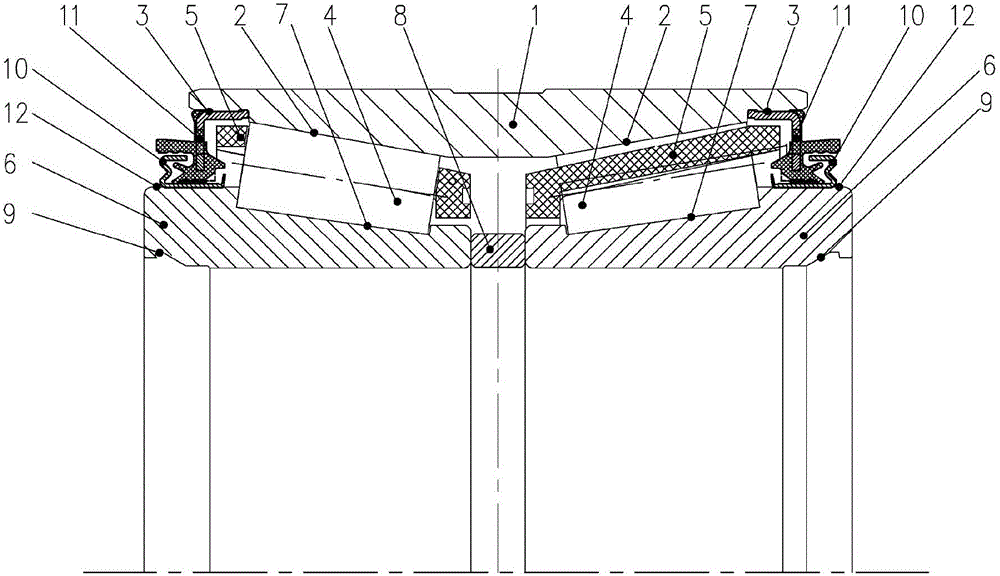

[0021] Such as figure 1 Shown is a semi-sectional view of an integrally sealed axlebox bearing for a locomotive axlebox, a kind of integrally sealed axlebox bearing for a locomotive axlebox. The outer ring 1 of the bearing has two symmetrical raceways 2, each on the inner diameter of the two ends of the outer ring 1. There is an annular tooth mouth 3, which is convenient to cooperate with the sealing assembly and improve the sealing performance; the rolling element 4 is placed on the pocket hole of the cage 5, and contacts with the bearing inner ring 6 raceway 7 to form an inner ring assembly, which is in the pocket of the cage 5 All the holes are loaded into the rolling body 4, the rolling body 5 will not fall out, and the rolling body 4 maintains good performance; the two inner ring assemblies are placed inside the outer ring 1 from both ends of the bearing outer ring 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com