Non-contact packed piston for ultralow-temperature refrigerator

A non-contact technology for ultra-low temperature refrigerators, applied in mechanical equipment, variable displacement pump components, machines/engines, etc., can solve problems affecting the stability of refrigeration performance of refrigerators, pistons scratching cylinders, and increased labyrinth seal gaps, etc. problems, to achieve the effect of reducing the difficulty of processing and assembly, ensuring the accuracy of shape and position, and ensuring the coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

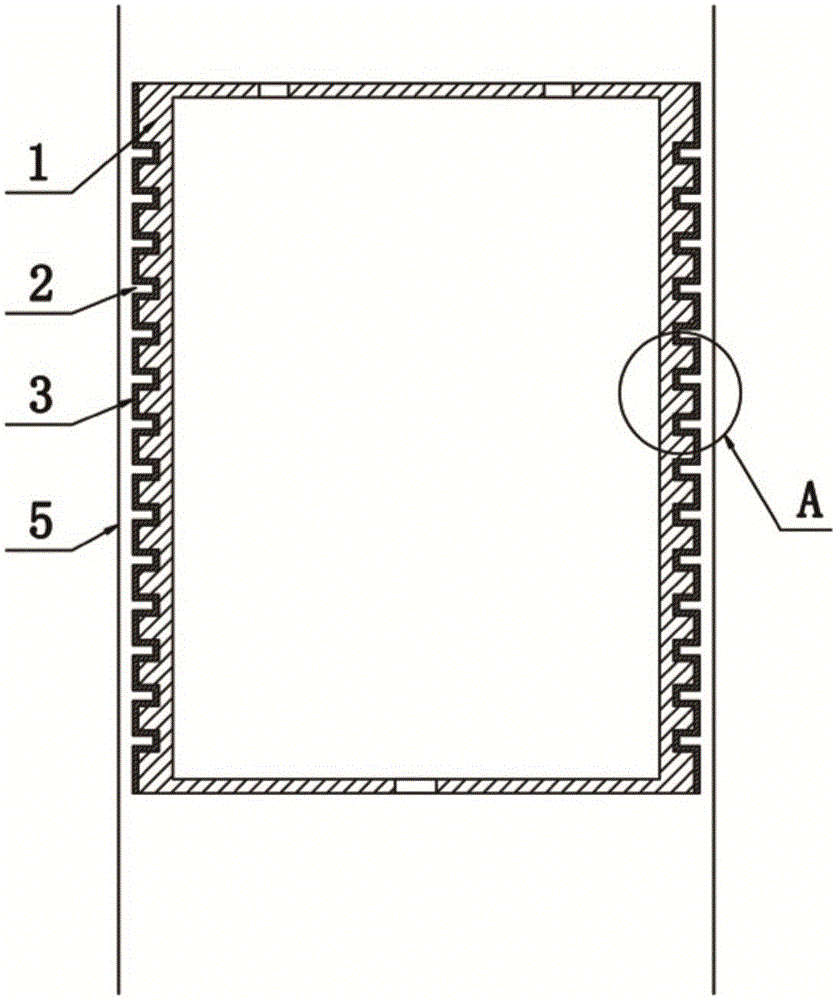

[0031] In order to better understand the improvements made by the present invention relative to the prior art, before describing the specific embodiments of the present invention in detail, the prior art mentioned in the background art will be described with reference to the accompanying drawings.

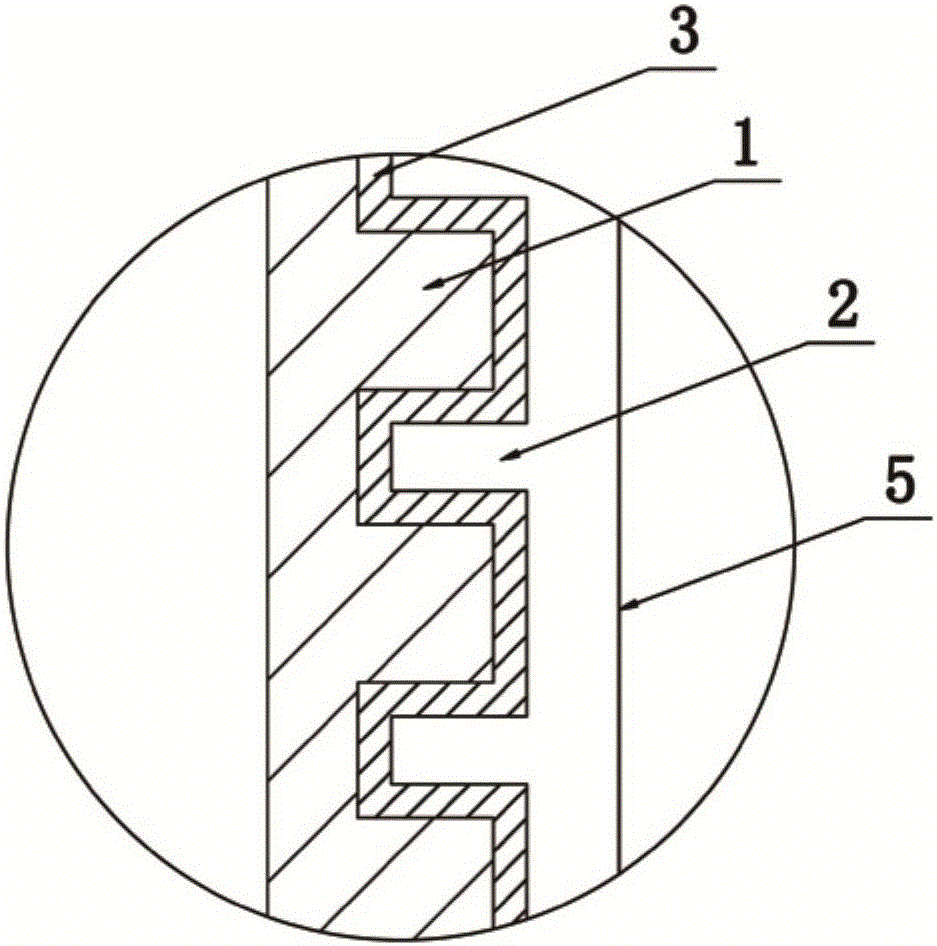

[0032] figure 1 Shown is the piston structure in the Chinese invention patent "Labyrinth Seal Piston for GM Refrigerator" mentioned in the prior art. The piston is located inside the cylinder 5 and is directly machined on the surface of the piston base 1 perpendicular to the axis of the piston base 1 , And then spray a layer of wear-resistant coating 3 on its surface. For comparison, figure 1 Enlarge the area A with groove 2 in the middle to get figure 2 . Observed figure 2 It can be seen that the groove 2 is directly processed on the piston base 1, which will weaken the overall strength of the piston base 1, and the uneven distribution of the strength of each part of the piston bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com