Environment-friendly cigarette package lined paper

A technology for lining paper and cigarettes, which is applied in wrapping paper, wrapping paper, packaging, etc., can solve the problems of insufficient ink and paper bonding, unclean peeling of paper, and easy wrinkling and warping of aluminized paper. The content of non-degradable components is low, which is conducive to the protection of the environment, and the pattern is clear and shiny.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

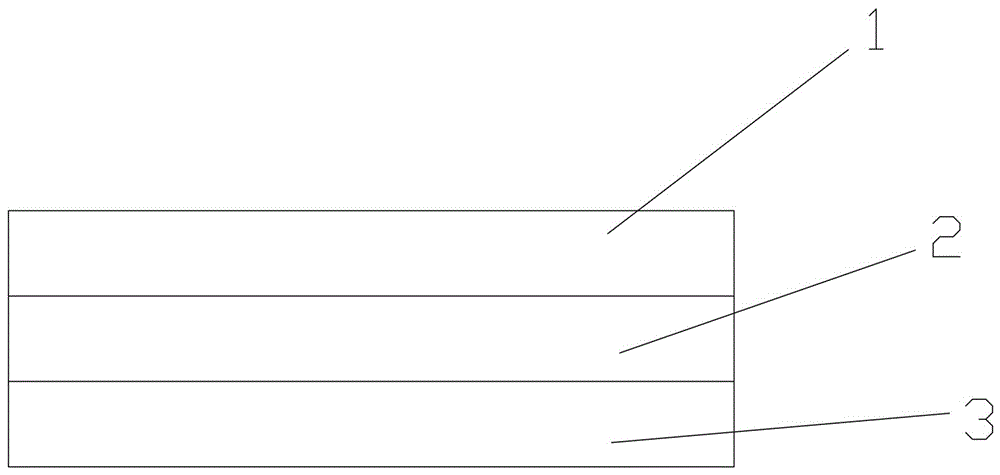

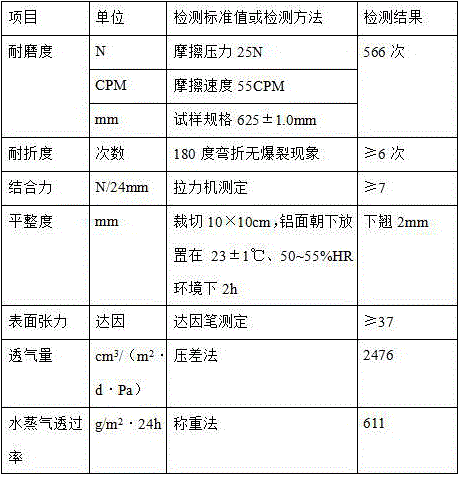

[0014] An environmentally friendly cigarette packaging lining paper, comprising a base paper 2 and a barrier layer 3, the base paper 2 and the barrier layer 3 are compounded by coating an adhesive, the base paper 2 has a coating layer 1, and the barrier layer 3 is composed of the following components in mass percentage Composition: polyvinyl alcohol 6%; polycaprolactone 10%; polyhydroxyalkanoate 10%; emulsifying wax 0.8%; montmorillonite 7%; zinc stearate 6%; the balance is water.

[0015] The adhesive comprises the following components in mass percent: 22% methyl acrylate, 23% methyl methacrylate, 7% methacrylic acid, 8% methyl acetate, 8% methyl tin mercaptide, 4% % bentonite, 2% toughening agent, and the balance is water.

Embodiment approach 2

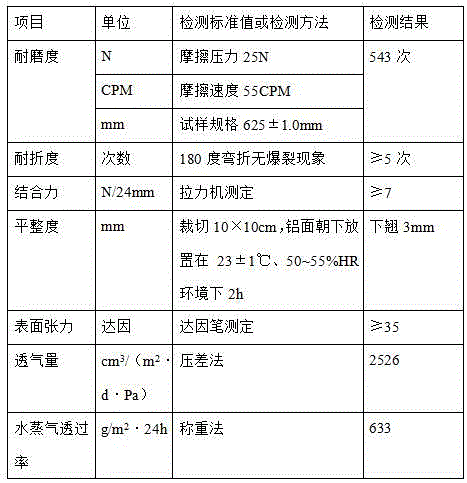

[0017] The barrier layer 3 of the packaging lining paper is composed of the following components in mass percentage: polyvinyl alcohol 5%; polycaprolactone 13%; polyhydroxyalkanoate 8%; emulsifying wax 0.5%; montmorillonite 1%; Zinc stearate 2%; the balance is water.

[0018] The adhesive comprises the following components in mass percent: 15% methyl acrylate, 10% methyl methacrylate, 4% methacrylic acid, 4% methyl acetate, 3% methyl tin mercaptide, 2% % bentonite, 1% toughening agent, and the balance is water.

Embodiment approach 3

[0020] The three barrier layers of the packaging lining paper are composed of the following components in mass percentage: polyvinyl alcohol 8%; polycaprolactone 19%; polyhydroxyalkanoate 5%; emulsifying wax 0.3%; montmorillonite 1%; Zinc stearate 1%; the balance is water.

[0021] The adhesive comprises the following components in mass percent: 13% methyl acrylate, 13% methyl methacrylate, 11% methacrylic acid, 1% methyl acetate, 2% methyl tin mercaptide, 2% % bentonite, 1% toughening agent, and the balance is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com