Joint lubricating material and preparation method thereof

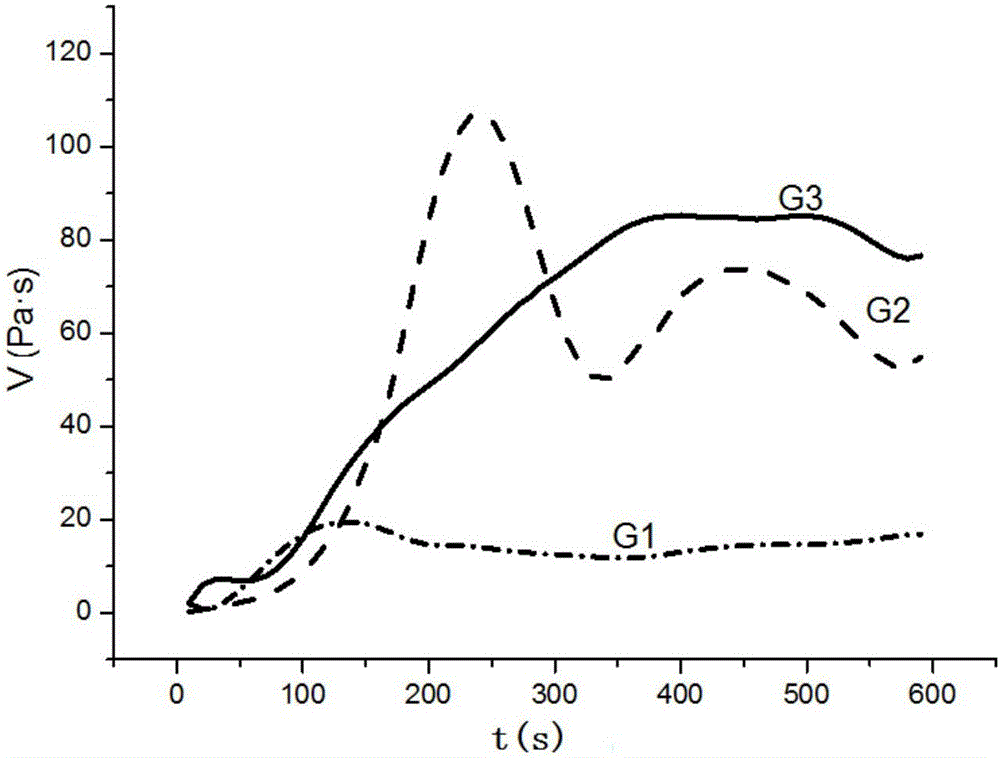

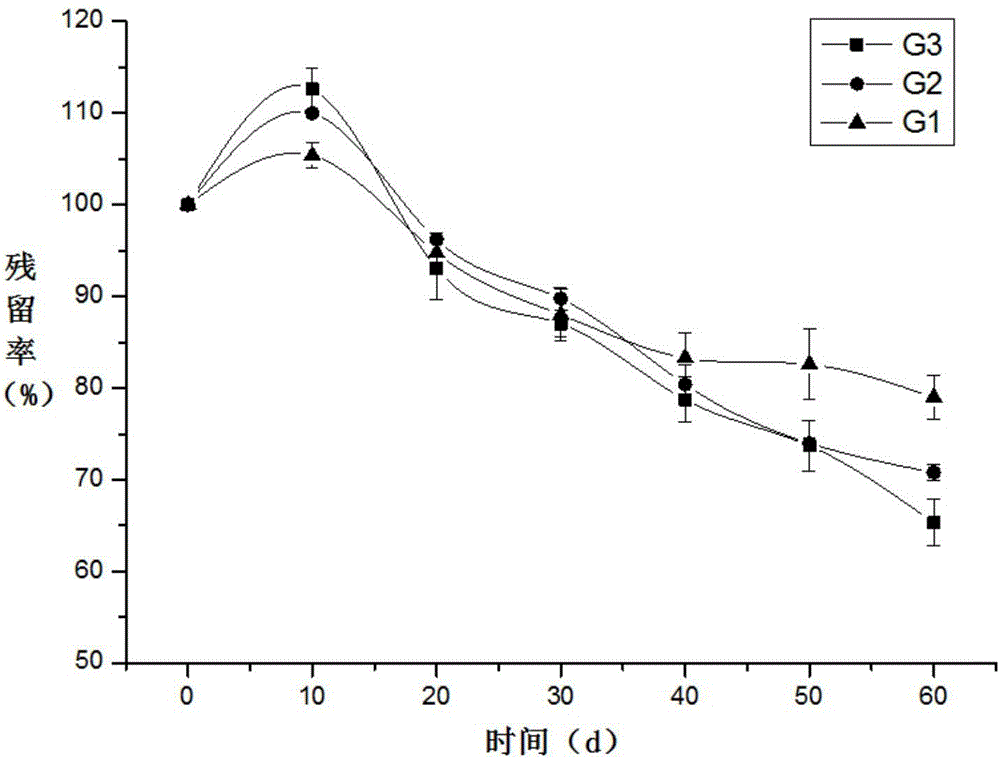

A technology for lubricating materials and joints, applied in the field of O-carboxymethyl chitosan hydrogel, which can solve problems such as the impact of histocompatibility in vivo, and achieve the effects of controllable gelation time, high water content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A1. Preparation of O-CMCH: Weigh 5.0g of chitin, and weigh 5.9g of NaOH to prepare a NaOH solution with a concentration of 20% by mass according to the ratio of chitin repeating unit to NaOH molar ratio of 1:6. Disperse the plain powder in NaOH solution, stir evenly, vacuumize in a vacuum drying oven for 30 minutes, and put it into a -20°C refrigerator overnight after the alkali penetration is complete. Thaw the next day, transfer the alkalized chitin into the reaction kettle, add 50mL of dispersant n-propanol, stir well at room temperature, add 1.86g of chloroacetic acid in four times (completely added within 1h), and react at a constant temperature of 10°C for 6h. After the reaction is finished, filter with suction, dissolve the filter residue in water, add hydrochloric acid to adjust the pH to about 8, and then filter with a 400-mesh filter cloth. The filtrate is ultra-filtered 5 times, and the volume compression ratio is 1 / 5 each time. 10,000, the concentrated solut...

Embodiment 2

[0042] A1. Preparation of O-CMCH: Weigh 5.0g of chitin, and weigh 11.03g of KOH to form a KOH solution with a mass percentage concentration of 25% according to the molar ratio of chitin repeating unit and KOH of 1:8.0. Disperse the plain powder in the KOH solution, stir evenly, vacuumize in a vacuum drying oven for 30 minutes, and freeze in a -20°C refrigerator overnight after the alkali has penetrated completely. After thawing the next day, transfer the alkalized chitin into the reaction kettle, add 75mL of dispersant isopropanol, stir well at room temperature, add 2.33g of chloroacetic acid in four times (completely added within 1h), and react at a constant temperature of 15°C for 5h. After the reaction is finished, filter with suction, dissolve the filter residue in water, add hydrochloric acid to adjust the pH to about 8, and then filter with a 400-mesh filter cloth. The filtrate is ultra-filtered 5 times, and the volume compression ratio is 1 / 5 each time. 10,000, the conc...

Embodiment 3

[0046] A1. Preparation of O-CMCH: Weigh 5.0g of chitin, and weigh 8.87g of NaOH to prepare a NaOH solution with a mass percentage concentration of 35% according to the molar ratio of chitin repeating unit and NaOH of 1:9.0. Disperse the plain powder in NaOH solution, stir evenly, vacuumize in a vacuum drying oven for 30 minutes, and put it into a -20°C refrigerator overnight after the alkali penetration is complete. Thaw the next day, transfer the alkalized chitin into the reaction kettle, add 90mL of dispersant isopropanol, stir well at room temperature, add 3.49g of chloroacetic acid in four times (completely added within 1h), and react at a constant temperature of 20°C for 3.5h . After the reaction is finished, filter with suction, dissolve the filter residue in water, add hydrochloric acid to adjust the pH to about 8, and then filter with a 400-mesh filter cloth. The filtrate is ultra-filtered 5 times, and the volume compression ratio is 1 / 5 each time. 10,000, the concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com