MVR belt sludge drying machine

A technology of belt drying machine and sludge, which is applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc. It can solve the problems of safety risks, lower oxygen content, high energy consumption, etc. problems, to achieve the effect of long service life, suppression of volatilization, and less wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

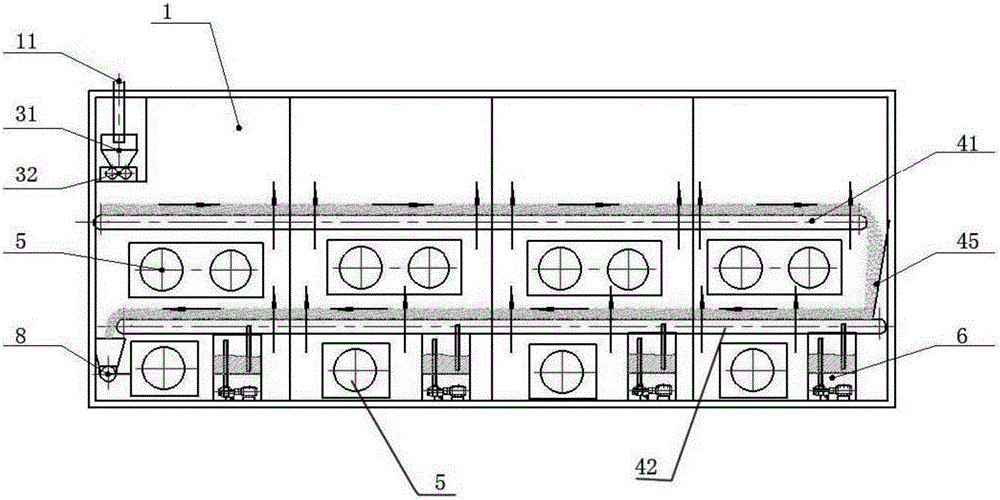

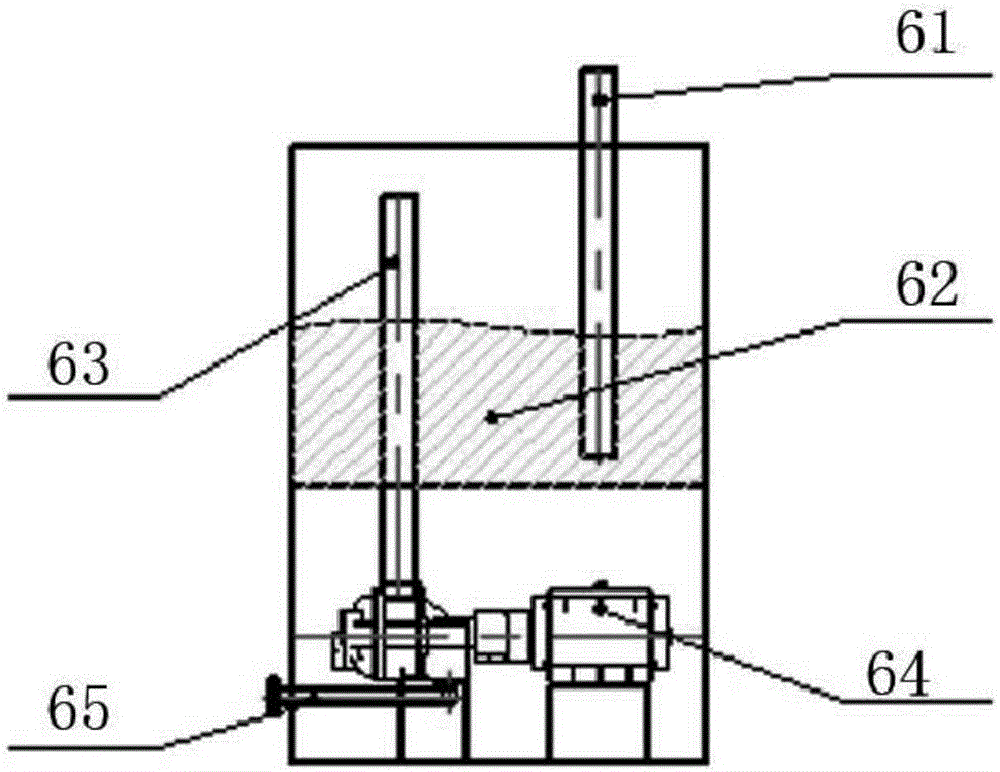

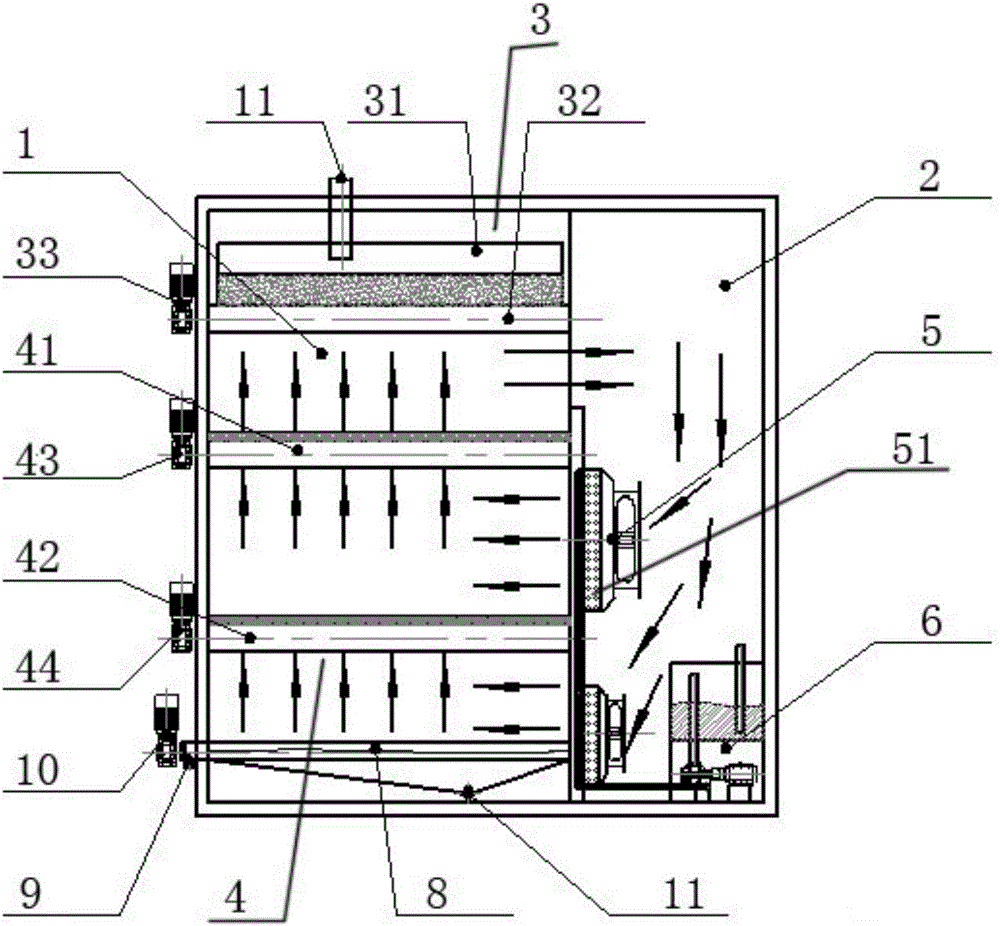

[0032] Such as figure 1 , figure 2 As shown, the MVR sludge belt dryer includes a drying box 1, an auxiliary box 2, a sludge forming device 3, at least one layer of mesh belt 4, a steam heater 5, an MVR vapor compression device 6 and a sludge exchange The heater 7, the auxiliary box 2 and the drying box 1 are connected through an air duct, and the drying box 1 is provided with at least one layer of mesh belt 4, and the upper part of one end of the mesh belt 4 is provided with a sludge feeding port 11, and the sewage Below the mud feed port 11 is a sludge forming device 3, which is used to form the sludge to be dried onto the mesh belt 4, and the steam heater 5 and the MVR vapor compression device 6 are installed in the drying box 1 in the auxiliary box 2 on the side.

[0033] The preferred two-layer mesh belt in this embodiment, the first la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com