A device and method for storing, unloading, and deodorizing raw sludge

A sludge storage and sludge technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve problems such as poor unloading, impact on the surrounding environment, and unpleasant smell of original sludge, and achieve good airtightness and pollution The effect of smooth mud discharge and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

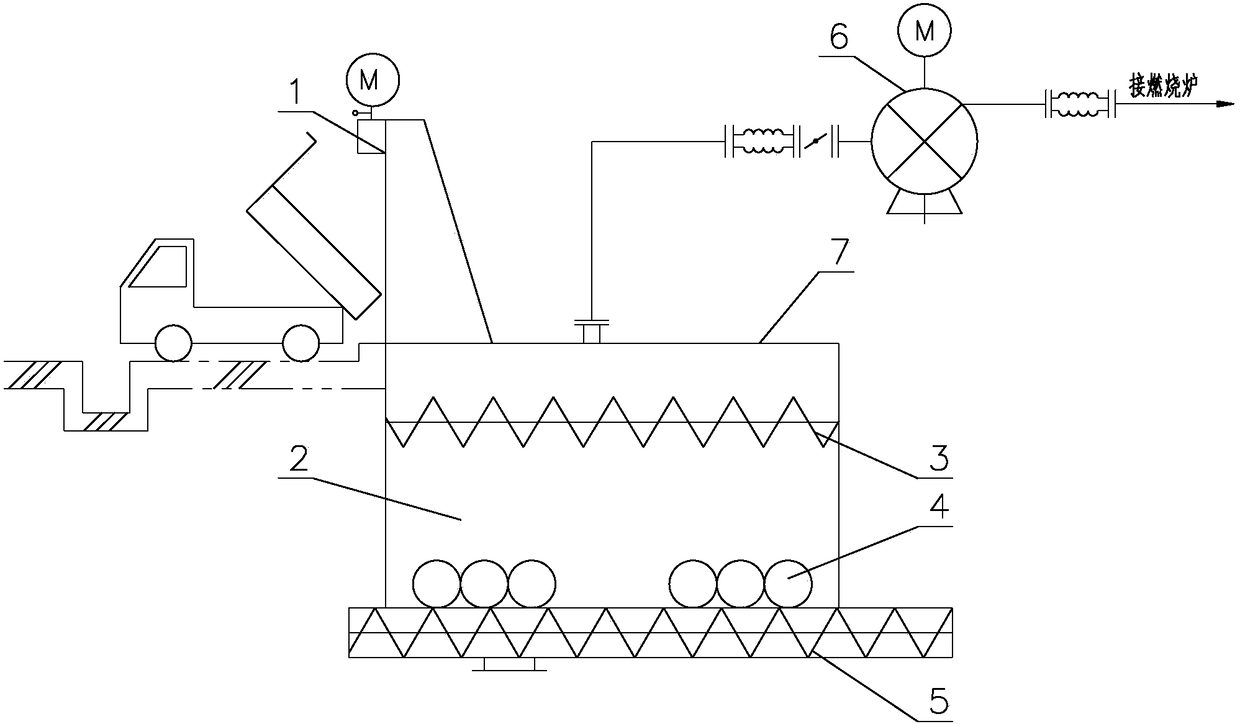

[0026] Such as figure 2 As shown, an original sludge storage, unloading and deodorization device includes a sludge tank 2, a leveling screw 3, a stirring screw 4, a discharge screw 5 and a deodorizing fan 6; the top of the sludge tank 2 is loaded An electric door 1 is provided on one side, a top cover 7 is provided on the top, and an exhaust pipe is provided in the middle of the top cover 7 to connect the combustion air inlet pipe of the combustion furnace through the deodorizing fan 6; A screw 5 and a sludge outlet are provided at the bottom of the discharge screw 5; a stirring screw 4 is provided above the discharge screw 5.

[0027] The leveling screw 3, the stirring screw 4, and the discharging screw 5 are all arranged horizontally, wherein the stirring screw 4 and the discharging screw 5 are vertically arranged.

[0028] The leveling screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com