Bend cutting device

A cutting device and elbow technology, which is applied in the field of pipe fittings processing, can solve the problems such as the difficulty of clamping, feeding and cutting that the efficient cutting and separation technology of elbows has not been solved satisfactorily, and achieves low production cost and fast clamping. , to ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

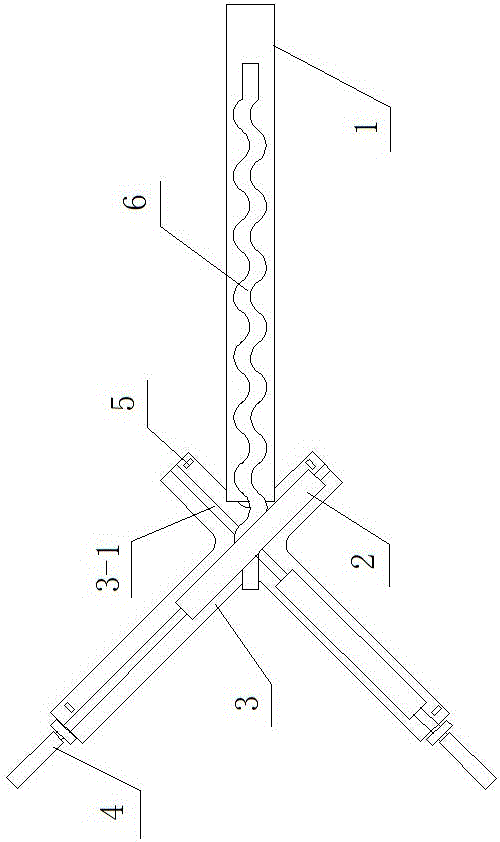

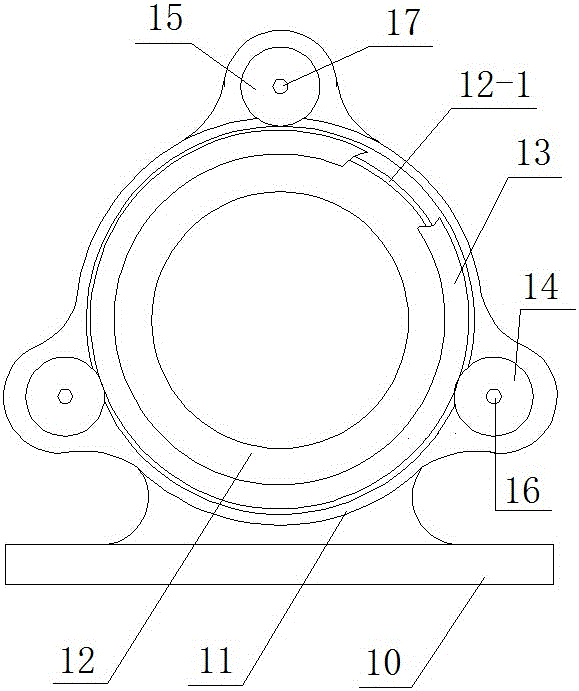

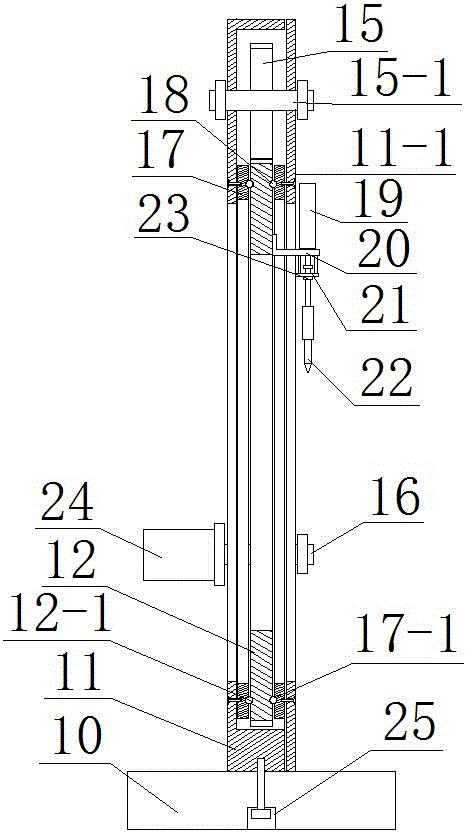

[0030] Such as figure 1 As shown, the elbow cutting device of the present invention includes a rotary laser cutting mechanism 2 and a blank feeding mechanism 1 , and the blank feeding mechanism 1 is located on one side of the rotary laser cutting mechanism 2 . The feeding direction of the billet feeding mechanism 1 is inclined to the rotation axis of the rotary laser cutting mechanism 2, so as to meet the cutting needs of the incision of the multi-joint elbow relative to the axis of the elbow. In view of the fact that the elbow cutting incisions are alternately at two angles relative to the axis of the elbow, the elbow cutting device of the present invention is provided with two rotary laser cutting mechanisms 2, and are set at different angles to alternately cut the elbow. The two rotary laser cutting mechanisms 2 can share a base 3 , and two sliding rails 3 - 1 are intersected on the top surface of the base 3 , respectively slidingly connected with the two rotary laser cutti...

Embodiment 2

[0041] see Figure 6 , as a further improvement of the technical solution of the first embodiment, a rotary mechanism can be set at the bottom of the rotary laser cutting mechanism 2, the rotary mechanism includes a base 3a and a push-pull cylinder 7, and the base 3a is connected to the rotary laser through a thrust bearing The cutting mechanism 2 is connected, and the push-pull cylinder 7 can be fixedly connected with the base 3a through a connector. The telescopic end of the push-pull cylinder 7 is hinged with the rotary laser cutting mechanism 2 through a hinged connector, and a rotation limiter is arranged on the base. In this structure, after the previous cut is completed, the push-pull cylinder 7 is activated, so that the rotary laser cutting mechanism 2 can rotate an angle to cut the next cut. The structure is simpler and brings a series of beneficial effects. The elbow cutting device can also be equipped with a controller (not shown in the figure), which is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com