Resistive welding electrode and method for spot welding steel and aluminum alloy workpieces with the resistive welding electrode

A technology of resistance welding and aluminum alloy, which is applied in the direction of resistance welding equipment, welding/welding/cutting items, welding equipment, etc., which can solve the problems of long-time placement and high consumption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

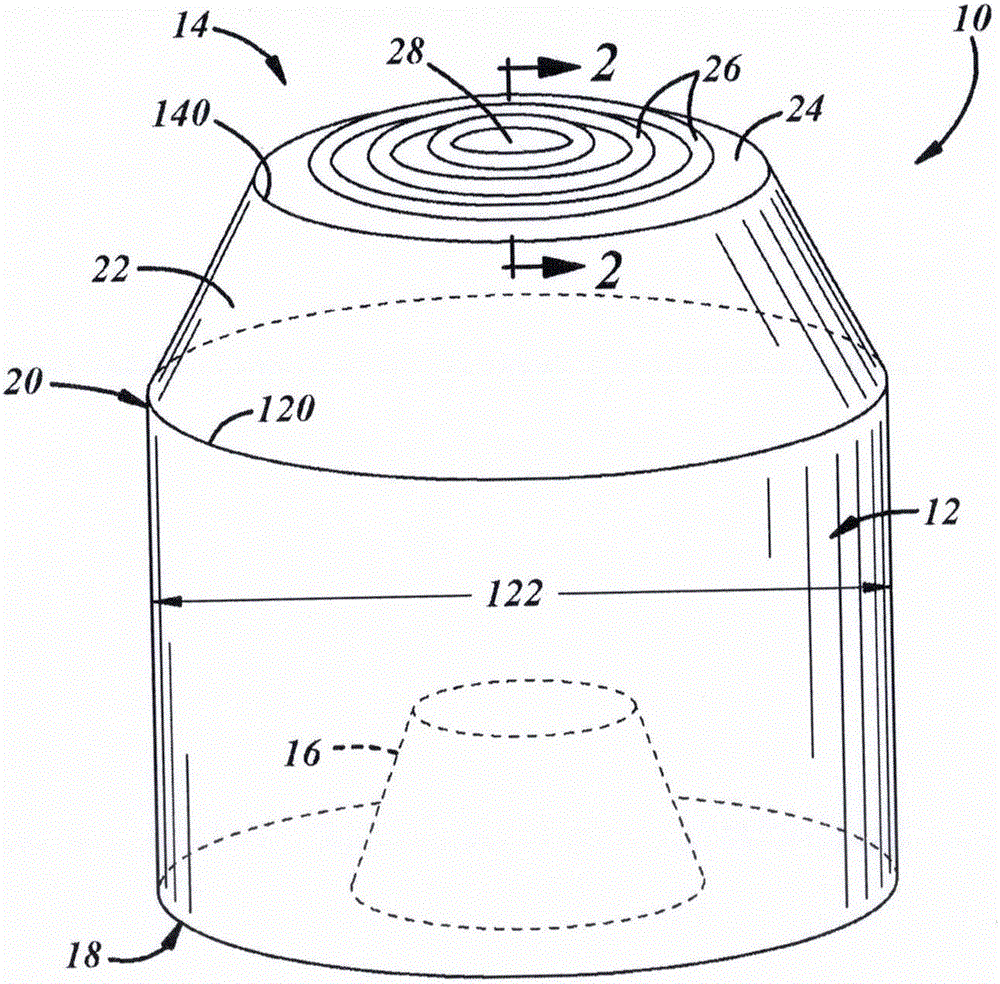

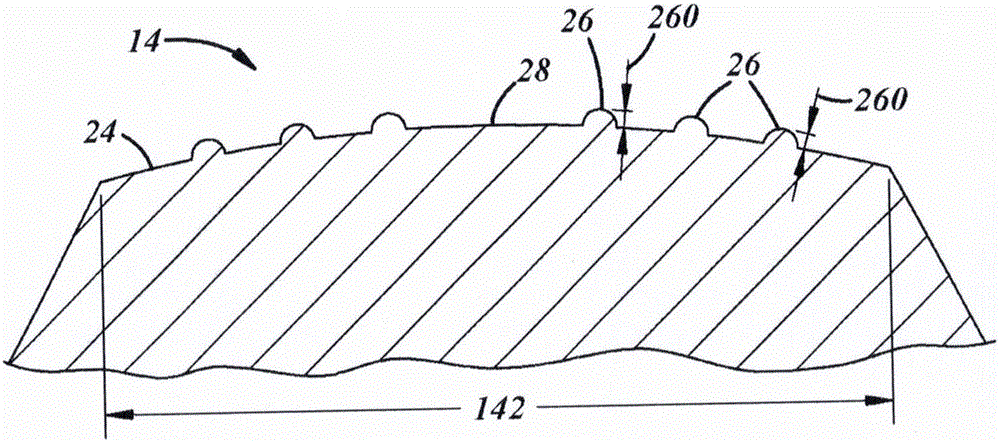

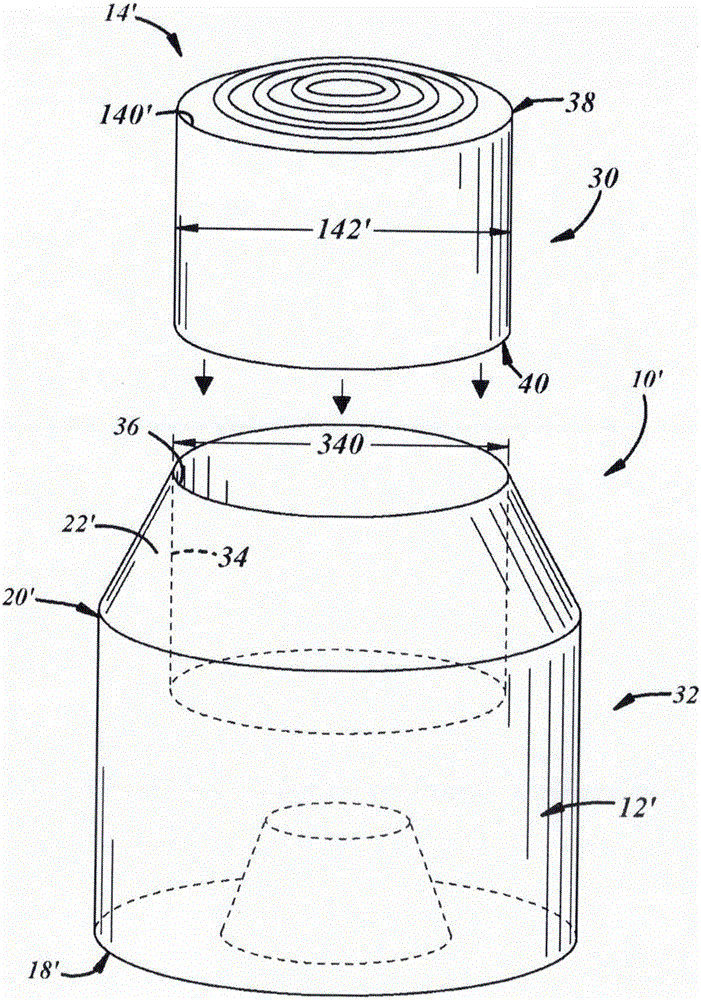

[0059] The resistance welding electrodes described below include at least a weld face (which may be smooth or contain raised surface features) composed of a refractory base material exhibiting an electrical conductivity less than or equal to that specified by the International Standard for Annealed Copper ( 65% of the conductivity of commercially pure annealed copper as defined by the IACS). In other words, the refractory base material has less than 3.8×10 7 S / m conductivity. Some examples of resistance welding electrodes are Figure 1-3 shown. When used for resistance spot welding workpiece stacks (which include aluminum alloy workpieces, which are placed in overlapping contact with steel workpieces, examples of which are in Figure 5-8 ), the resistance welding electrode contacts and presses against the aluminum alloy workpiece, while the second welding electrode contacts and presses against the steel workpiece. In addition, if Figure 12-13 As shown and described below...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com