Layered ultrasonic impact treatment method capable of optimizing structure and performance of weld

A technology of ultrasonic impact and treatment method, used in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of high equipment requirements, difficult on-site construction, and inability to change the structure of the weld, to optimize mechanical properties, weld The effect of improved impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

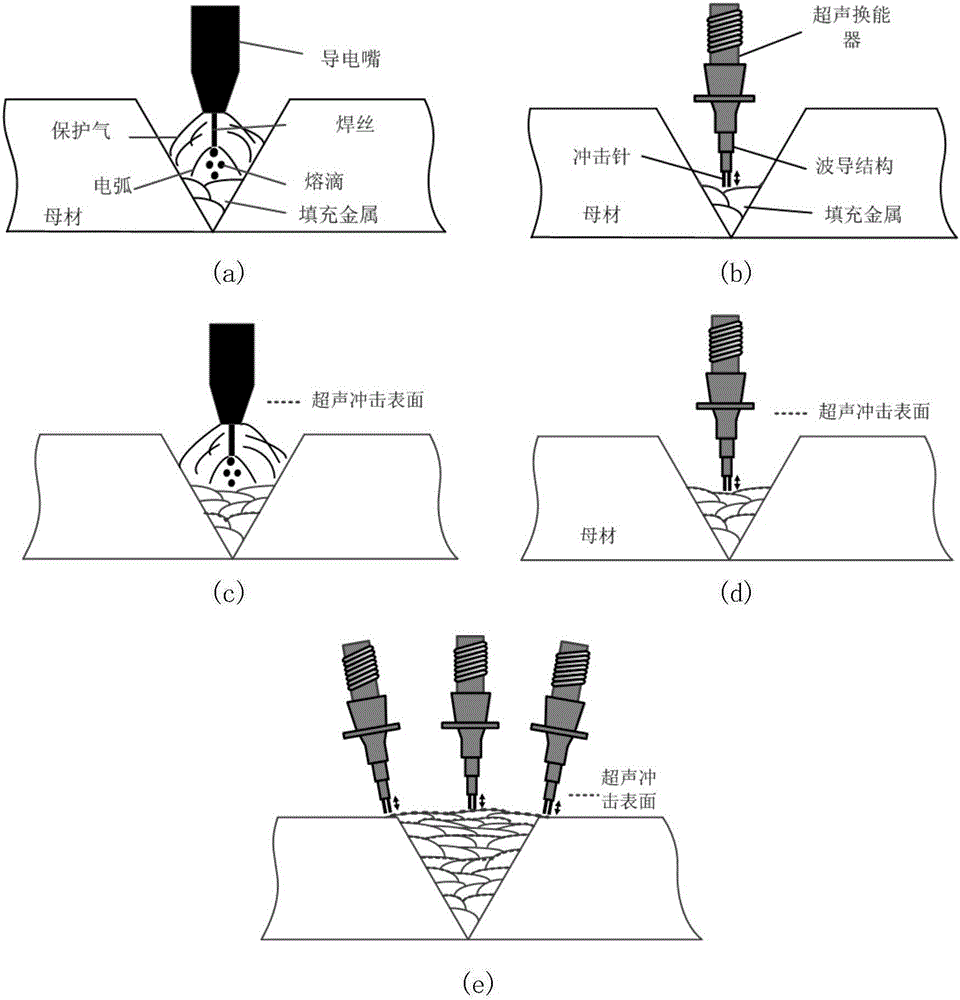

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

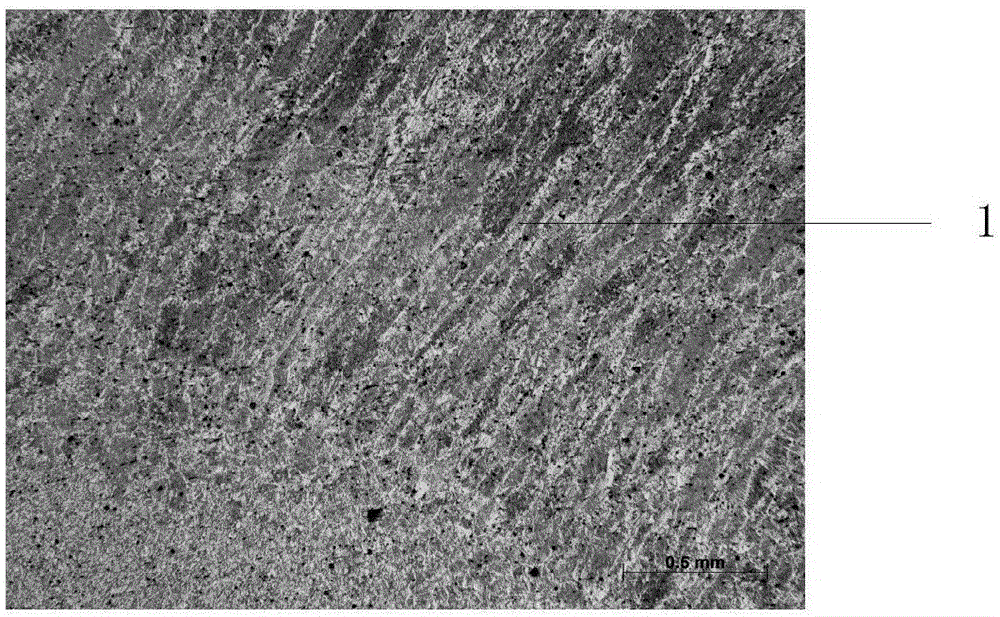

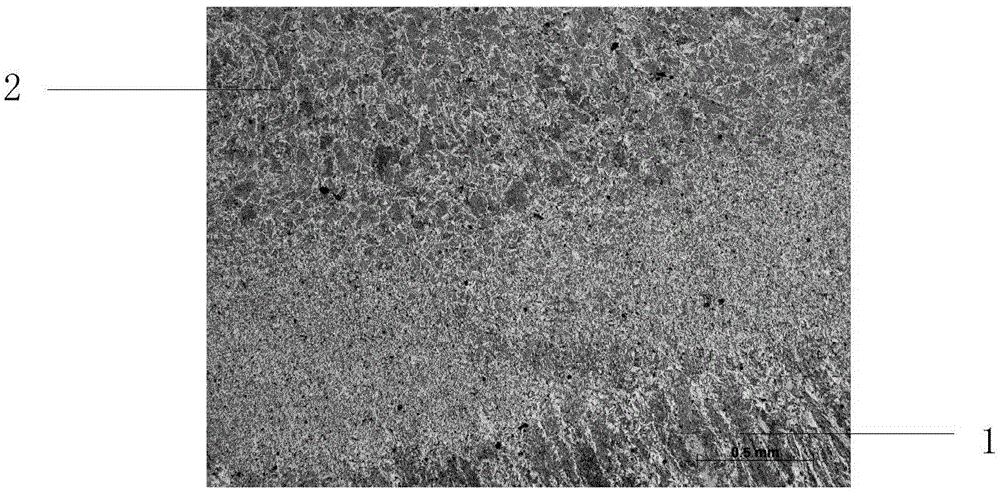

[0025] In this embodiment, two test pieces A and B are welded under carbon dioxide gas shielding. The test piece A is a weldment without ultrasonic impact, and the test piece B is a weldment processed by a layered ultrasonic impact method. Both test piece A and test piece B are 55mm thick Q345 steel plates, the weld groove angle is 60 degrees, the welding method is carbon dioxide gas shielded welding, and test piece A and B are welded under the same welding parameters. Specimen A is used as a comparative test, and the welding process and parameters are consistent with those of layered ultrasonic impact test B. like figure 1 As shown, the specific steps of the process are as follows:

[0026] Step 1: Preparations before welding: Clean the base metal in the weld groove of test piece A and test piece B with alcohol to remove the oil stain attached to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com