Grinding device for cement production

A grinding and cement technology, applied in grain processing, etc., can solve the problems affecting the use effect of cement, uneven powder size, low production efficiency, etc., achieve good particle size uniformity, improve use effect, hardness and durability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

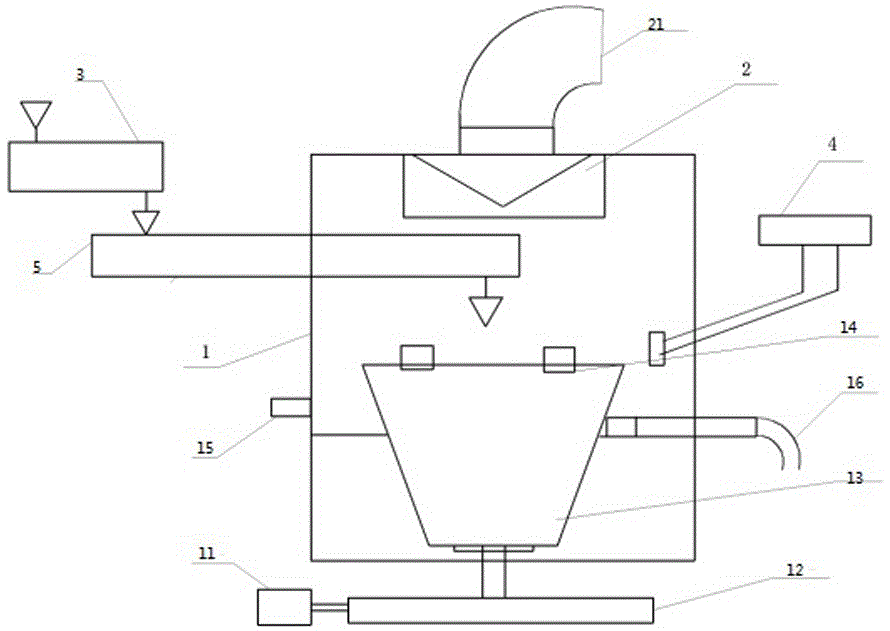

[0013] Such as figure 1 As shown, the present invention provides a grinding device for cement production, including a pulverizer body 1, the bottom end of the pulverizer body 1 is provided with a grinding disc 13 with an upward opening, and the grinding disc 13 is connected to a decelerating machine located outside the pulverizer body 1. machine 12, the reducer 12 is connected to the motor 11, a feeder 3 is arranged on one side of the pulverizer body 1, and a dryer 5 for receiving materials in the feeder 3 is arranged below the feeder 3, so The dryer 5 extends into the pulverizer body 1 and is located above the grinding disc 13. The dryer 5 is used to send materials to the grinding disc 13. The top of the pulverizer body 1 is located directly above the grinding disc 13 and is equipped with an intelligent powder selection device. Machine 2, the intelligent powder separator 2 is provided with a fine powder outlet 21, one side of the pulverizer body 1 is provided with an air inle...

Embodiment 2

[0015] Such as figure 1 As shown, the material is first placed in the feeder 3 and falls into the grinding disc 13 after being dried by the dryer 5. The material moves from the middle to the periphery under the action of the centrifugal force generated by the rotation of the grinding disc 13. The 13 raceways are fully pulverized by extrusion and grinding, and the electrical control system 4 is started, which sprays air into the grinding disc 13, and the air enters the grinding disc 13 and rotates up, bringing the pulverized materials to the grinding disc 13. Go to the upper powder separator 2 for powder selection, the coarse particles fall naturally, and at the same time mix with the newly added materials, and then enter the grinding table 13 again, and the fine particle clinker passes through the powder separator 2 from the fine powder outlet 21 After passing through a stainless steel filter screen, it is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com