Preparation method of iron ion croscarmellose in-situ growing Prussian-blue microsphere adsorbing material

A technology of carboxymethyl cellulose and cross-linked carboxymethyl, which is applied in the field of preparation of iron ion cross-linked carboxymethyl cellulose in-situ grown Prussian blue microsphere adsorption material, achieving simple preparation process, low energy consumption, and easy synthesis The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

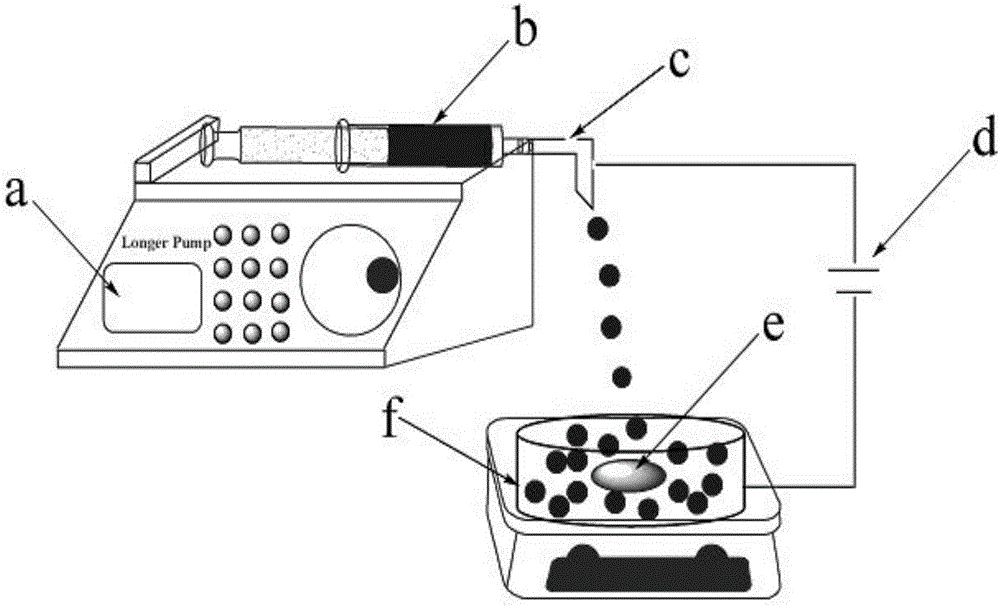

[0040] A preparation method for iron ion cross-linked carboxymethyl cellulose in-situ growth Prussian blue microsphere adsorption material, comprising the following steps:

[0041] Step 1, dissolving carboxymethyl cellulose in ultrapure water, stirring for 6 hours to obtain a sol with a concentration of 3 wt%, and ultrasonically degassing the sol for 10 minutes; the ultrasonic power of the ultrasonic degassing is 150W, and the ultrasonic frequency is 20KHz; The viscosity of the carboxymethyl cellulose is 1400mpa.s;

[0042] Step 2, use the electrospray device to electrospray the ultrasonically degassed sol into the receiving device with a concentration of 6wt% iron ion solution, and stir the iron ion solution during the electrospraying process; Add 2 mL of glutaraldehyde dropwise, stir for 12 h at a speed of 350 r / min, and filter to obtain iron ion-loaded gel microspheres;

[0043] Step 3. Place 7 g of the gel microspheres prepared in step 2 in a circulating water type vacuum...

Embodiment 2

[0045] A preparation method for iron ion cross-linked carboxymethyl cellulose in-situ growth Prussian blue microsphere adsorption material, comprising the following steps:

[0046] Step 1, dissolving carboxymethyl cellulose in ultrapure water, stirring for 5 hours to obtain a sol with a concentration of 3 wt%, and ultrasonically degassing the sol for 12 minutes; the ultrasonic power of the ultrasonic degassing is 1000W, and the ultrasonic frequency is 24KHz; The viscosity of the carboxymethyl cellulose is 1000mpa.s;

[0047] Step 2, use the electrospray device to electrospray the ultrasonically degassed sol into the receiving device with a concentration of 7wt% iron ion solution, and stir the iron ion solution during the electrospraying process; Add 0.2 mL of glutaraldehyde dropwise, stir for 13 h at a speed of 250 r / min, and filter to obtain iron ion-loaded gel microspheres;

[0048] Step 3: Place 8 g of the gel microspheres prepared in step 2 in a circulating water vacuum f...

Embodiment 3

[0050] A preparation method for iron ion cross-linked carboxymethyl cellulose in-situ growth Prussian blue microsphere adsorption material, comprising the following steps:

[0051] Step 1, dissolving carboxymethyl cellulose in ultrapure water, stirring for 6 hours to obtain a sol with a concentration of 5 wt%, and ultrasonically degassing the sol for 14 minutes; the ultrasonic power of the ultrasonic degassing is 800W, and the ultrasonic frequency is 20KHz; The viscosity of the carboxymethyl cellulose is 1200mpa.s;

[0052] Step 2, use the electrospray device to electrospray the ultrasonically degassed sol into the receiving device with a concentration of 9wt% iron ion solution, and stir the iron ion solution during the electrospraying process; Add 0.5 mL of glutaraldehyde dropwise, stir for 18 h at a speed of 200 r / min, and filter to obtain gel microspheres loaded with iron ions; the electrospray device includes a high-voltage power supply, a syringe pump, a syringe and a rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com