Dust removal waste gas purification treatment equipment

A treatment equipment and exhaust gas purification technology, applied in chemical instruments and methods, external electrostatic separators, electrode structures, etc., can solve problems affecting the health of operators, poor operating environment for collecting cotton wool, and increased fan power, so as to save energy. Consumption, removal of lint, and reduction of drag coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

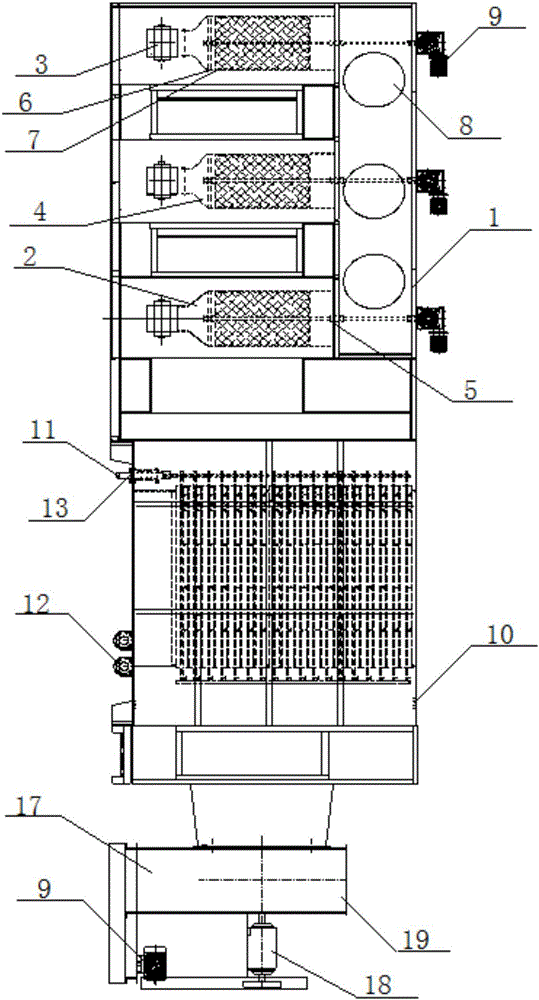

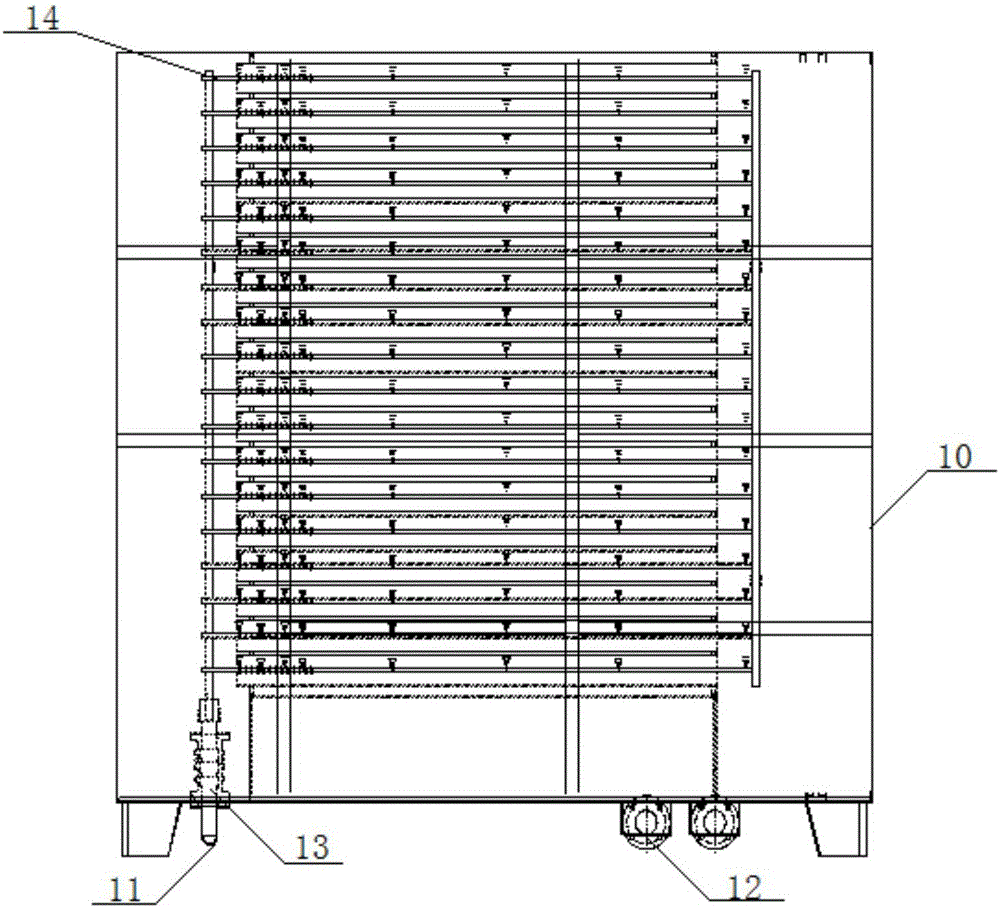

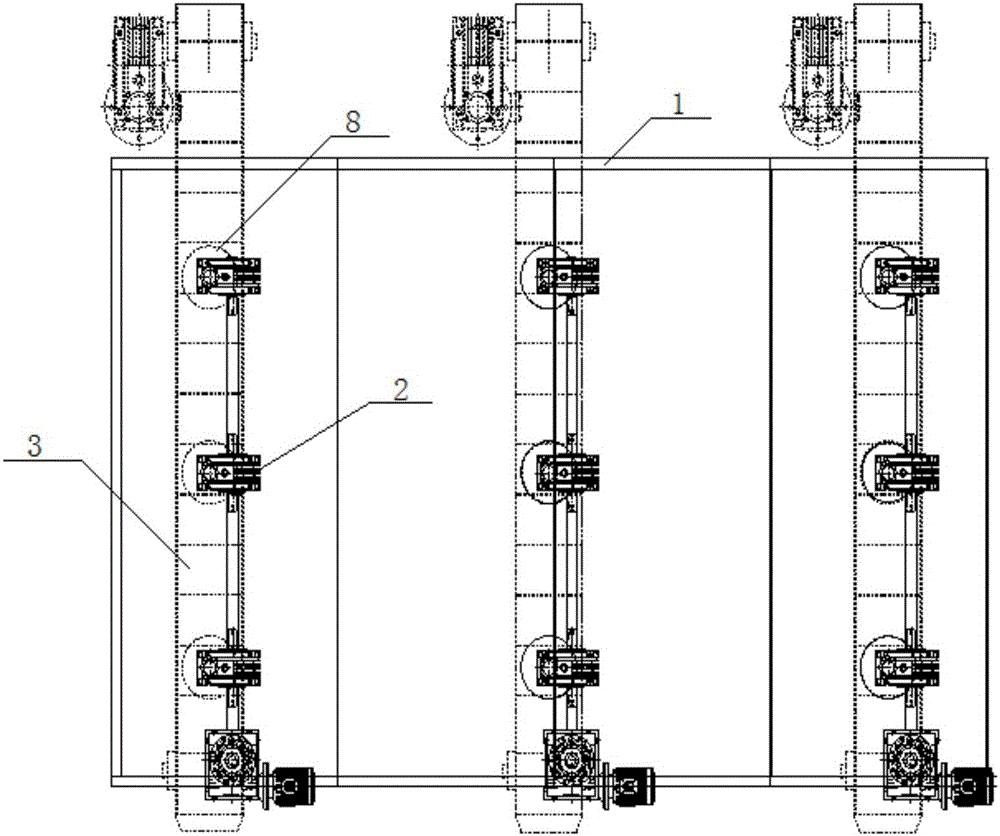

[0027] Such as Figure 1~7 The schematic diagram of the structure of the dust removal and exhaust gas purification treatment equipment of the present invention is shown; it includes a dust removal device and a high-voltage ionization device. Axis 5, scraper 6, nylon mesh 7, air inlet 8, motor 9, second box 10, water inlet 11, drain 12, insulating flange pipe 13, high-frequency and high-voltage electrostatic tube 14, gear piece 15, water outlet Hole 16, integrated fan 17, pulley 18, air outlet 19 and positive voltage tube 20.

[0028] In the first box body 1 of the dust removal device, there are multiple electric reducer rotary cloth bags 2 parallel to each other in the vertical direction. One of the more preferred solutions is to set up three electric reducer rotary cloth bags 2 without a license. Conveyor belts 3 are arranged at the bottom of the three electric reducer rotary bags 2 arranged in a row; three conveyor belts 3 are arranged parallel to each other in the first bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com