Method for eliminating sulfur dioxide in sulfited semi-finished fruits

A technology of sulfur dioxide and sulfur storage of fruit, which is applied in the direction of food science, etc., can solve the problems of lack of Cantonese-style preserved fruit desulfurization process, unfavorable preserved fruit production process, and increase the time of desulfurization process, so as to achieve positive local characteristics and economic significance, improve The effect of raw material appearance, synergistic color protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

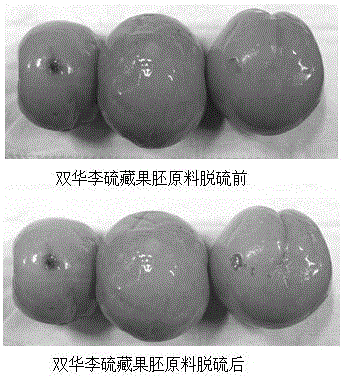

[0050] Example 1 Selection of desulfurization method

[0051] 1. Select the appropriate desulfurization method for the raw material of Cantonese-style preserved fruit sulfur storage.

[0052] (1) Raw materials: Cantonese-style preserved fruit Shuanghua plum, olive, bergamot, plum, and hawthorn slices.

[0053] Each fruit embryo was divided into 6 groups for testing.

[0054] (2) Method:

[0055] Group 1: Soak fruit embryos in 30% acetic acid solution and heat to 50°C.

[0056] Group 2: Soak in 4% citric acid solution at 80°C for 20 minutes.

[0057] Group 3: heating, soaking and rinsing method: repeatedly soak and rinse the fruit embryos with hot water, soak for 12 hours during the day, and change the water every hour; soak for 12 hours at night without changing the water.

[0058] Group 4: Soak in 0.04% sodium hydroxide solution for 8 hours.

[0059] Group 5: Ozone desulfurization in a closed environment.

[0060] (3) The desulfurization effect of the postembryons before ...

Embodiment 2

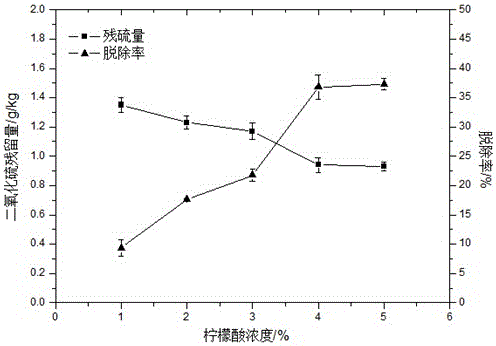

[0064] Example 2 Optimization test of citric acid solution concentration

[0065] In this example, the volume concentration of the citric acid solution was used as the single factor variable, and the citric acid solution was soaked for 15 minutes at 80° C. to optimize the concentration of the citric acid solution. For other operations, refer to Example 1. The test results are attached figure 2 As shown, as the concentration of citric acid solution increases, the sulfur content gradually decreases and the desulfurization rate increases gradually. Taking other factors into consideration, a volume concentration of 1-5% is selected, preferably a volume concentration of 2-4%, and most preferably a volume concentration of 4%.

Embodiment 3

[0066] Example 3 Optimization Test of Heating Conditions

[0067] In this example, the soaking heating temperature is taken as the single factor variable, and the soaking heating temperature is soaked in 4% citric acid solution for 15 minutes, and the optimization experiment of the soaking heating temperature is carried out, and other operations refer to Example 1. The test results showed that with the increase of soaking heating temperature, the sulfur content tended to decrease gradually, but when the temperature was too high, it would cause severe damage to the pericarp of the fruit embryo, soft pulp tissue and severe browning. Therefore, taking other factors into consideration, the heating temperature is selected to be 60°C to 90°C, preferably 70°C to 90°C, and most preferably 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com