Prebiotics-added formula milk powder suitable for premature infants and infants with low birth weight and preparation method thereof

A technology for low birth weight and formula milk powder, which is applied in the fields of milk preparations, dairy products, and applications, can solve the problems such as the inability to meet the growth and development needs of premature infants and low birth weight infants, and achieves protection of normal development and enhancement of immunity. , the effect of enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

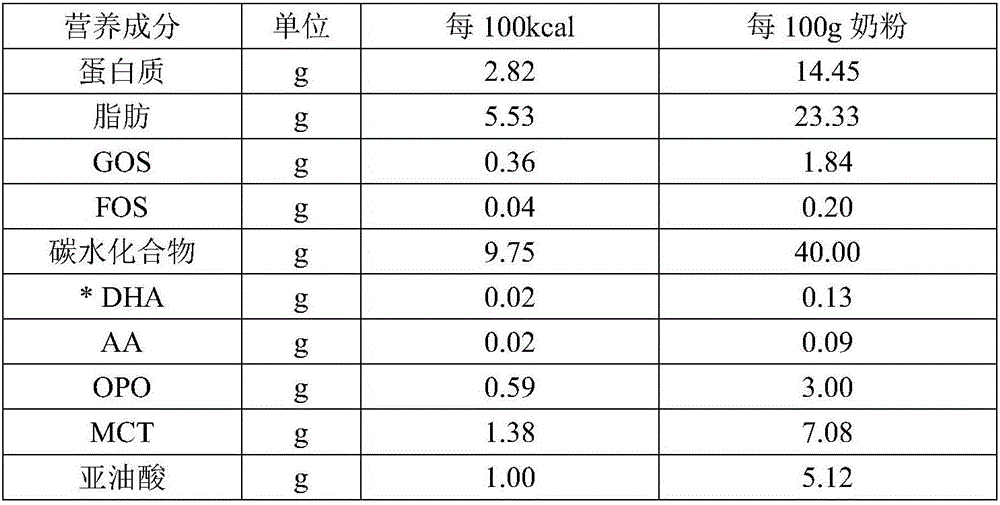

Embodiment 1

[0030] In this example, 1 kg of formula milk powder for premature infants and low birth weight infants is prepared by mixing the following components and weight percentages: 1200 g of whole milk, 250 g of D90 desalted whey powder, 30 g of whey protein powder (WPC80), and 30 g of mixed prebiotics , mixed edible vegetable oil 100g, docosahexaenoic acid (DHA) 1.5g, arachidonic acid (ARA) 0.2g, organic structure oil 1,3-dioleic acid, 2-palmitic acid triglyceride (OPO) 35g, medium chain triacylglycerol (MCT) 25g, vitamin premix 3g, mineral premix 20g, inositol 0.7g, choline bitartrate 0.5mg, taurine 70mg, L-carnitine tartrate 45mg, nuclear Glucoside 140mg.

[0031] The distribution ratio of each component and weight percentage of the mixed prebiotic is: 54% of galacto-oligosaccharide, 6% of fructo-oligosaccharide, 10% of transgalactoside oligosaccharide and 30% of lacto-oligosaccharide.

[0032] The proportion of components and weight percentages of the mixed edible vegetable oil ...

Embodiment 2

[0052] The formula milk powder for premature infants and low birth weight infants produced in 1kg is made by mixing the following components and weight percentages: 150g whole milk powder, 240g D90 desalted whey powder, 15g whey protein powder (WPC80), 80g mixed prebiotics, mixed and eaten Vegetable oil 110g, docosahexaenoic acid (DHA) 1g, arachidonic acid (ARA) 0.8g, organic structure oil 1,3-dioleic acid, 2-palmitic acid triglyceride (OPO) 40g, medium chain Triacylglycerol (MCT) 35g, vitamin premix 2.5g, mineral premix 20g, inositol 1g, choline bitartrate 0.8mg, taurine 80mg, L-carnitine tartrate 50mg, nucleotide 200mg.

[0053] The distribution ratio of each component and weight percentage of the mixed prebiotic is: 54% of galacto-oligosaccharide, 6% of fructo-oligosaccharide, 10% of transgalactoside oligosaccharide and 30% of lacto-oligosaccharide.

[0054] The distribution ratio of each component and weight percentage of the mixed edible vegetable oil is as follows: 45% o...

Embodiment 3

[0067]The formula milk powder for premature infants and low birth weight infants produced in 1kg is made by mixing the following components and weight percentages: 200g skimmed milk powder, 260g D90 desalted whey powder, 10g whey protein powder (WPC80), 50g mixed prebiotics, mixed edible vegetable oil 150g, docosahexaenoic acid (DHA) 0.8g, arachidonic acid (ARA) 0.6g, organic structure oil 1,3-dioleic acid, 2-palmitic acid triglyceride (OPO) 45g, medium chain Triacylglycerol (MCT) 30g, vitamin premix 2g, mineral premix 20g, inositol 1g, choline bitartrate 0.8mg, taurine 80mg, L-carnitine tartrate 50mg, nucleotide 400mg.

[0068] The distribution ratio of each component and weight percentage of the mixed prebiotic is: 54% of galacto-oligosaccharide, 6% of fructo-oligosaccharide, 20% of inulin-oligosaccharide, 10% of lactitol, and 10% of oligosaccharide of fructo-oligosaccharide.

[0069] The distribution ratio of each component and weight percentage of the mixed edible vegetabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com