Facility using circulated water for aquaculture and method thereof

An aquaculture, water body technology, applied in chemical instruments and methods, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as non-recyclable use, achieve fast growth, obvious economic benefits, and facility path design clever effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

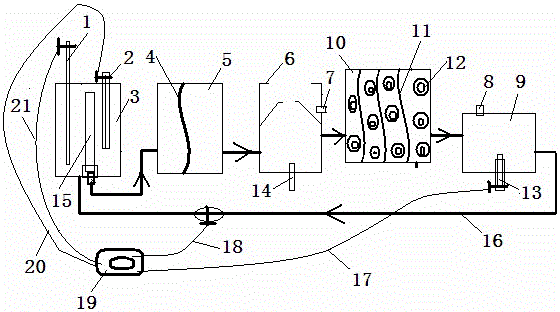

[0028] like figure 1 An aquaculture facility using a circulating water body is shown, having the following ponds or tanks connected in sequence:

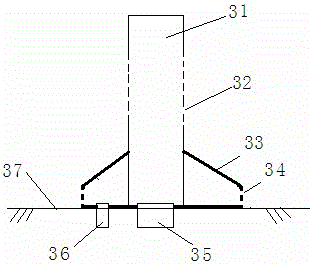

[0029] 1) Aquatic pond 3, where separation components, air pipe 1 and temperature regulating pipe 2 are installed. like figure 2 As shown, the separation assembly includes a fish and shrimp retaining ring 33 and a solid-liquid separation device 31 , a plurality of solid waste discharge holes 34 are distributed on the fish and shrimp retaining ring 33 , and a plurality of aqueous solution discharge holes 32 are distributed on the solid-liquid separation device 31 . The fish and shrimp retaining ring 33 is arranged on the periphery of the solid-liquid separation device 31, and the bottom of the pool between the two is connected with a solid waste discharge hole 34, which is connected to a solid waste discharge pipe 36; the solid-liquid separation device 31 is internally connected to the waste water outlet and waste water discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com