Method for increasing hardness of copper-based multi-component alloy

A multi-alloy, copper-based technology, applied in the field of metal materials, can solve the problems of deteriorating the electrical conductivity of copper alloys, limited hardness of copper alloys, complicated processes, etc., and achieve the effects of increased density, distribution and dispersion, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The material used is a copper-based multi-element alloy cast by metal mold, and its chemical composition (mass fraction wt%) is: Cr 0.58%, Se 0.720%, Al 0.23%, Te 0.64%, Fe 0.21%, and the balance is Cu. The copper alloy sample was placed on a CS-IB type six-sided top press for high-pressure aging treatment. The pressure was 2GPa, the heating temperature was 480°C, the holding time was 120min, and the power was turned off and the pressure was released to cool to room temperature. The test results of the hardness value are shown in Table 1.

Embodiment 2

[0018] The composition and process of the materials used are the same as in Example 1. In this example, the pressure is 5GPa, the heating temperature is 550°C, the holding time is 60min, and the power is turned off and the pressure is released to cool to room temperature. The test results of the hardness value are shown in Table 1.

Embodiment 3

[0020] The composition and process of the materials used are the same as in Example 1. In this example, the pressure is 3GPa, the heating temperature is 500°C, the holding time is 100min, and the power is turned off and the pressure is released to cool to room temperature. The test results of the hardness value are shown in Table 1.

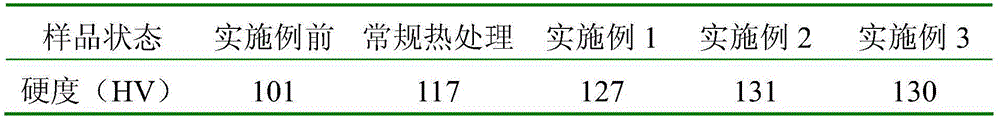

[0021] Table 1 Hardness test results of copper-based multi-element alloys in different states

[0022]

[0023] Note: Conventional heat treatment (solid solution + aging): solid solution at 950°C for 60 minutes + aging at 470°C for 120 minutes.

[0024] The above experimental results show that the copper-based multi-element alloy has a higher hardness value after being treated by the method of the present invention, which is higher than the hardness value before the embodiment and after the conventional heat treatment process (solid solution+aging).

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com