Release film for green sheet manufacturing, release film manufacturing method for green sheet manufacturing, green sheet manufacturing method, and green sheet

A technology for a printed circuit substrate and a manufacturing method, which is applied in the field of release films for the manufacture of printed circuit substrates, can solve the problems of local thickness and unevenness of pinholes that are prone to occur in printed circuit substrates, and achieve excellent peelability, excellent smoothness, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

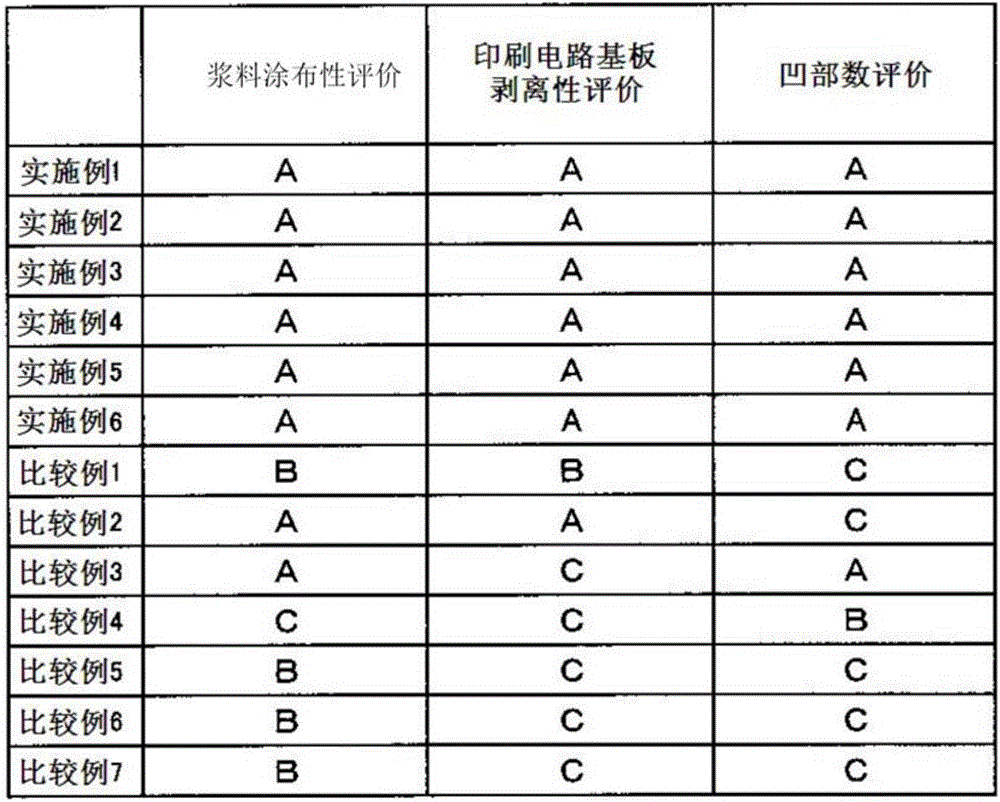

Examples

Embodiment 1

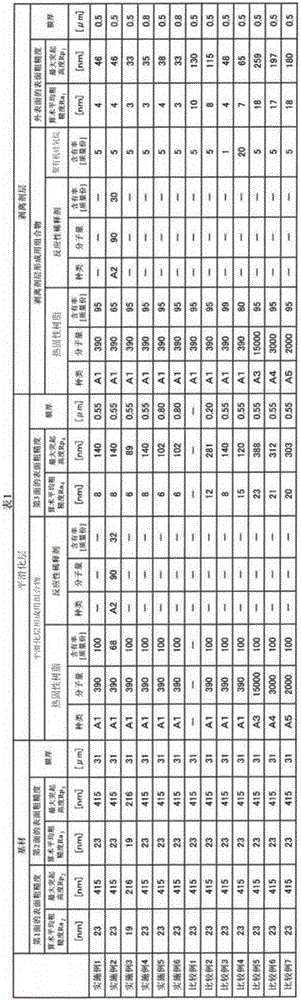

[0219] First, prepare a biaxially oriented polyethylene terephthalate film [thickness: 31 mm, arithmetic average roughness Ra of the first surface] as a base material 2 : 23nm, the maximum protrusion height Rp of the first surface 2 : 415nm, the arithmetic mean roughness Ra of the second surface 3 : 23nm, the maximum protrusion height Rp of the second surface 3 : 415nm].

[0220] Then, 100 parts by mass of melamine resin [manufactured by Mitsui Cytec Co., Ltd., trade name "Symel 303", hexamethoxymethylmelamine, mass average molecular weight 390, solid content 100 mass %], and 5 p-toluenesulfonic acid as an acidic catalyst Parts by mass and a mixed solvent (mass ratio 4 / 1) of isopropanol and isobutanol were mixed to obtain a composition for forming a smoothing layer with a solid content of 15% by mass.

[0221] Then, the obtained composition for smoothing layer formation was apply|coated on the 1st surface 111 of the base material 11 with the bar coater, and the 1st coating ...

Embodiment 2

[0225] Except having used the composition for smoothing layer formation obtained as follows, and the composition for release agent layer formation, it carried out similarly to Example 1, and manufactured the release film for printed circuit board manufacture.

[0226] Melamine resin [manufactured by Mitsui Cytec Corporation, trade name "Symer 303", hexamethoxymethylmelamine, mass average molecular weight 390, solid content 100% by mass] 65 parts by mass, and a diol compound [2- Methyl-1,3-propanediol, manufactured by Tokyo Chemical Industry Co., Ltd., mass average molecular weight 90, solid content 100%] In a mixture of 30 parts by mass, 5 parts by mass of p-toluenesulfonic acid as an acidic catalyst, and isopropanol and isopropanol A mixed solvent of butanol (mass ratio 4 / 1) was used to obtain a composition for forming a smoothing layer with a solid content of 15% by mass.

[0227] In addition, 65 parts by mass of melamine resin [manufactured by Mitsui Cytec Co., Ltd., trade ...

Embodiment 3

[0229] Except using biaxially oriented polyethylene terephthalate film [thickness: 31mm, arithmetic mean roughness Ra of the 1st side 2 : 19nm, the maximum protrusion height Rp of the first surface 2 : 216nm, the arithmetic mean roughness Ra of the second surface 3 : 19nm, the maximum protrusion height Rp of the second surface 3 : 216 nm], except that it was used as a base material, it carried out similarly to Example 1, and produced the release film for printed circuit board manufacture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com