Resin foam and foamed member

A technology of resin foam and components, which is applied in the direction of synthetic resin layered products, transportation and packaging, chemical instruments and methods, etc., can solve the problems of changing the physical properties of foam and complex production processes, etc., and achieve excellent processability, The effect of preventing foam breakage and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

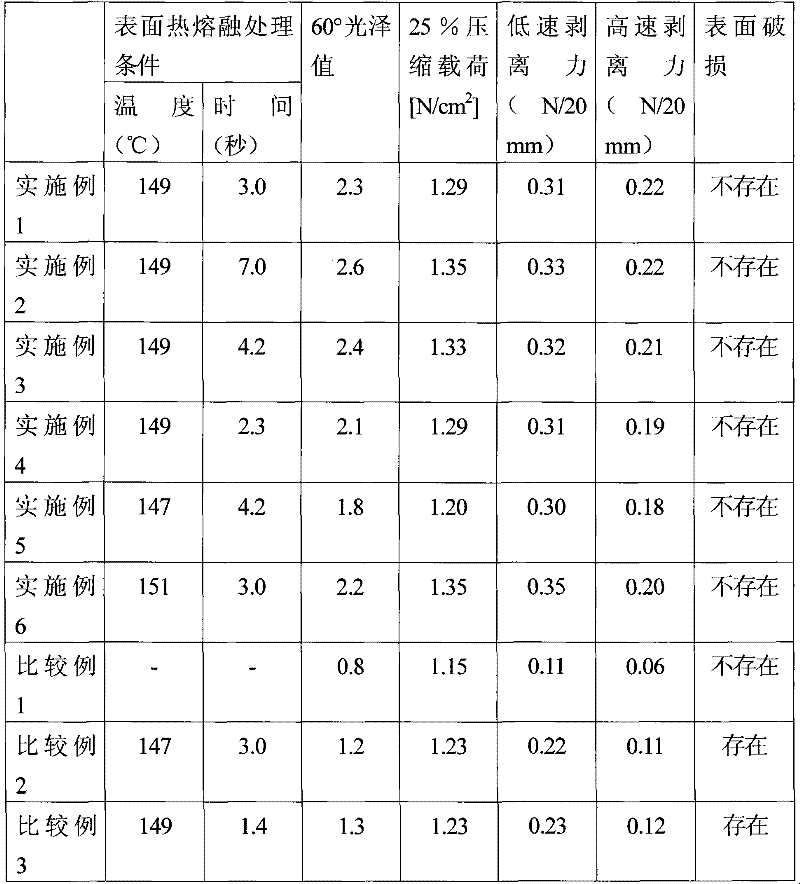

Embodiment 1

[0123] Using a twin-screw extruder manufactured by Japan Steel Works (Japan Steel Works, Ltd.,) (JSW), at 200°C, 40 parts by weight of polypropylene [melt flow rate (MFR): 0.35g / 10min ], 55 parts by weight of polyolefin-based elastomer [melt flow rate (MFR): 6g / 10min, JIS hardness A: 79°], 6 parts by weight of carbon black (trade name "Asahi#35", produced by Asahi Carbon produced by the company) and 10 parts by weight of magnesium hydroxide (average particle diameter: 0.7 μm) as a powder flame retardant are kneaded, then extruded into strips, water-cooled, and formed into pellets. The softening point of the pellets is 155°C and the density of the pellets is 0.95 g / cm 3 .

[0124] The pellets were charged into a single-screw extruder manufactured by Nippon Steel Works, and carbon dioxide gas was injected under a pressure of 22 (19 after injection) MPa in an environment of 220°C. After the carbon dioxide is fully saturated, the pellets are cooled to a temperature suitable for ...

Embodiment 2

[0129] One surface of the resin foam (A) was subjected to surface heat fusion treatment in the same manner as in Example 1 except that the resin foam (A) was brought into contact with the heat roll for 7.0 seconds. As a result, a resin foam having a surface with a 60° gloss value of 2.6 was obtained.

Embodiment 3

[0131] In the same manner as in Example 1, except that the resin foam (A) was brought into contact with the heat roll for 4.2 seconds, one surface of the resin foam (A) was subjected to surface heat fusion treatment. As a result, a resin foam having a surface with a 60° gloss value of 2.4 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com