Electronic device's waterproof and drop-proof shell and its preparation method

An electronic equipment, drop-proof technology, applied in the direction of electrical equipment casing/cabinet/drawer, electrical components, sealed casing, etc., can solve the problem that carbon fiber materials cannot realize the waterproof function of mobile phones, and cannot meet the functional requirements, toughness and impact resistance of 3C electronic products Poor resistance and other problems, to achieve the effect of poor impact resistance and easy cracking, excellent drop resistance and water resistance, and the whole machine is light and thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

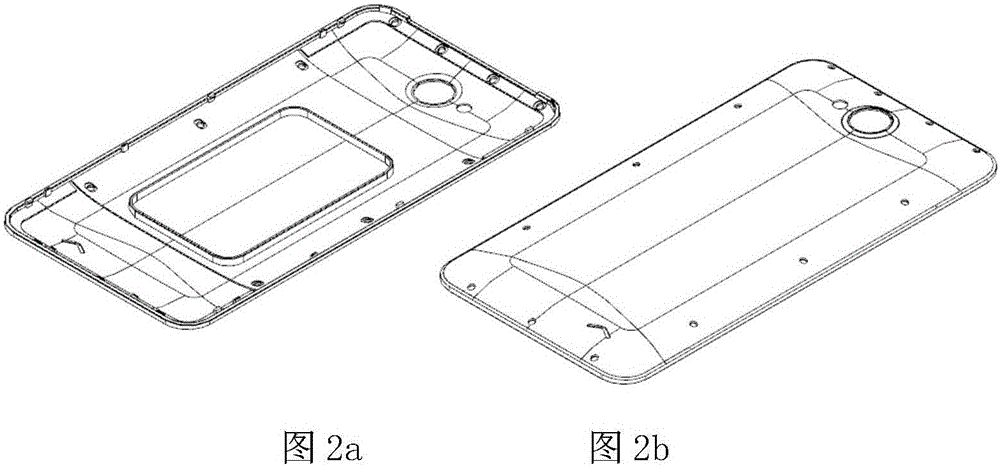

[0042] refer to Figure 1a to Figure 5b , in one embodiment, a waterproof and drop-proof housing for electronic equipment, including a carbon fiber sheet structure 1, an injection molding structure 2 integrally formed on the back and surroundings of the carbon fiber sheet structure 1, and an integrally formed on the carbon fiber sheet structure 1 The soft rubber protection structure 3 on the front of the sheet structure 1 and the silicone waterproof structure 4 integrally formed on the injection molding structure 2, wherein the carbon fiber sheet structure 1 and the injection molding structure 2 are combined to form a fixed shape A part of the injection molding structure 2 forms a package on the peripheral side of the carbon fiber sheet structure 1, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com