LC resonance and PTC (positive temperature coefficient) resistance band-based electric power storage device heating method

A technology of electric storage devices and resistance bands, which is applied in battery/fuel cell control devices, transportation and packaging, battery/battery traction, etc., and can solve problems such as complex circuit structure and impact on battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

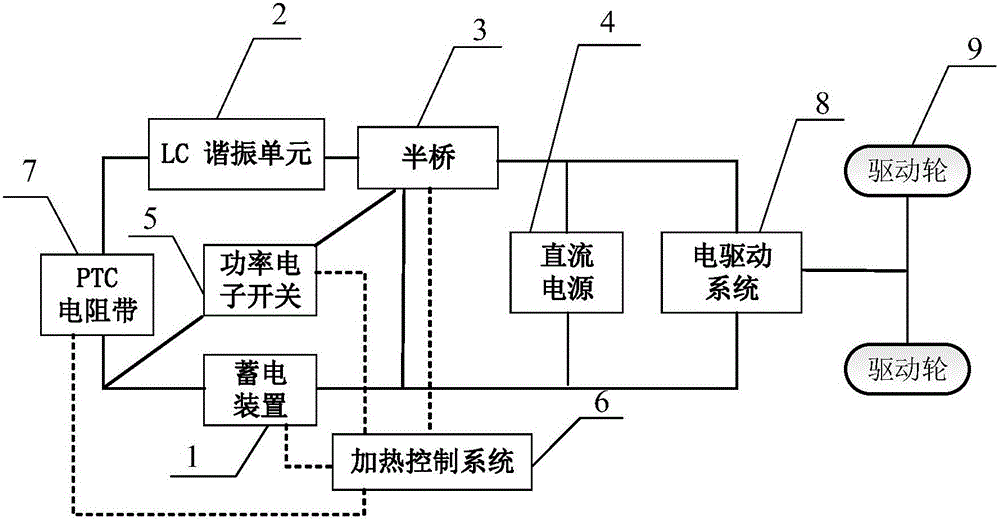

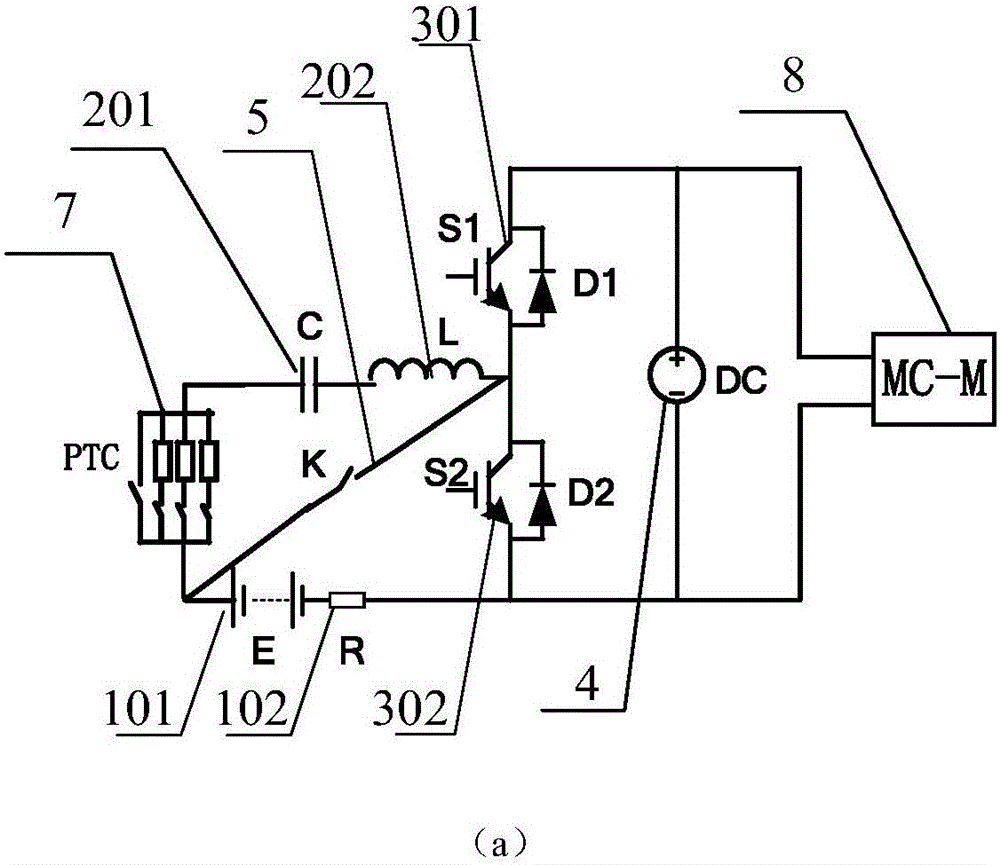

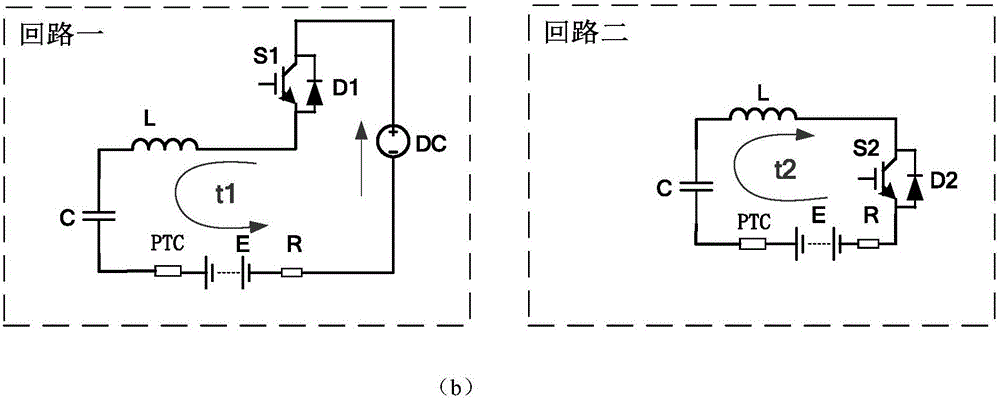

[0067] Such as figure 1 As shown, the power supply system for heating based on LC resonance and PTC resistance band of the present invention consists of a DC power supply 4, a heating control system 6, a power electronic switch 5, a half bridge 3, an LC resonance unit 2, an electrical storage device 1, and a PTC resistance The belt 7 is composed; the DC power supply 4 is connected to the half bridge 3; the heating control system 6 obtains the status information of the power storage device 1, controls the power electronic switch 5 to be on and off, adjusts the resistance value of the PTC resistance belt 7, and determines The switching frequency of half-bridge 3; as figure 2 As shown in (a), the half bridge 3 includes an upper bridge arm 301 and a lower bridge arm 302, the upper and lower bridge arms can use IGBT or MOSFET power tubes, the negative pole of the power storage device 1 is connected to the lower bridge arm 301, and the positive pole is connected to the lower bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com