discharge lamp

A technology for discharge lamps and discharge tubes, which is applied to discharge tubes/lamp parts, gas discharge lamp parts, and main electrodes of discharge tubes, etc., can solve the problems of reduced electron emission characteristics and exhaustion of emitters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

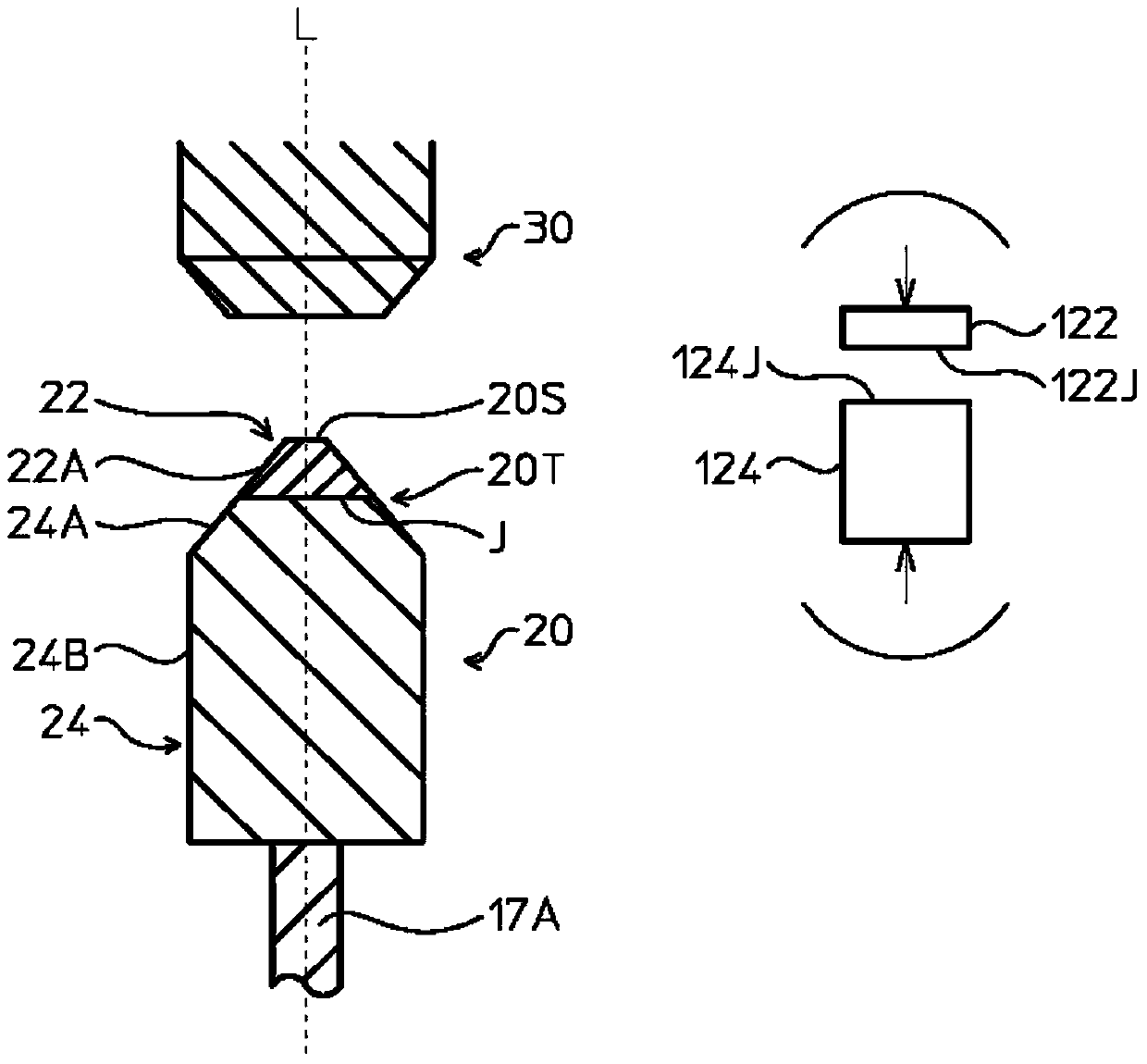

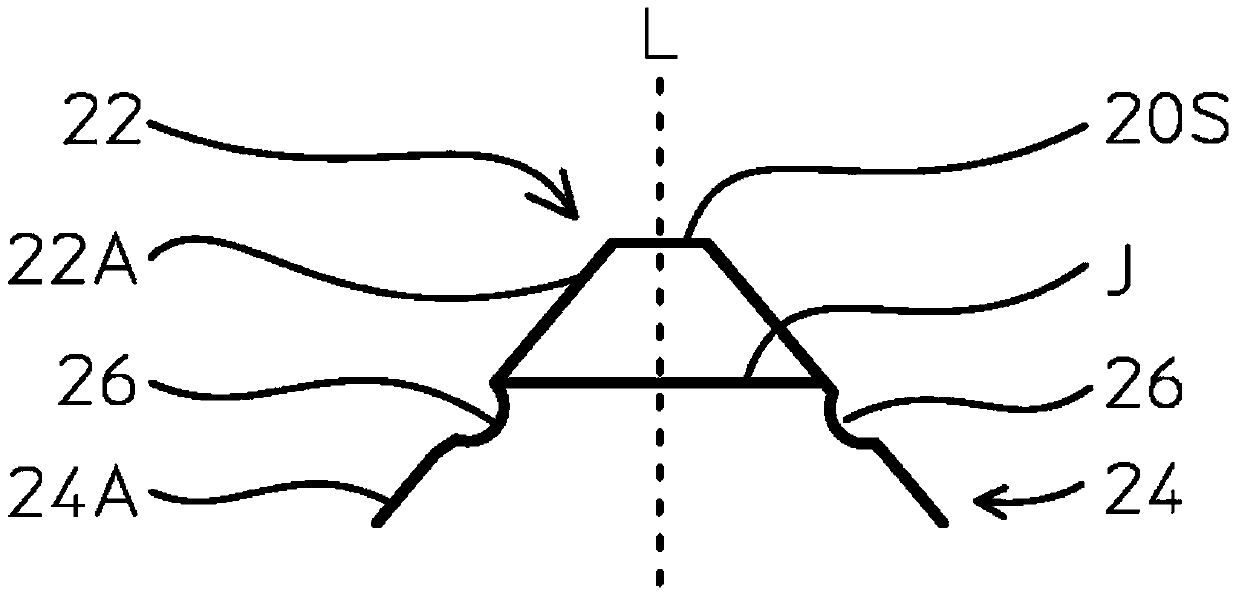

[0014] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

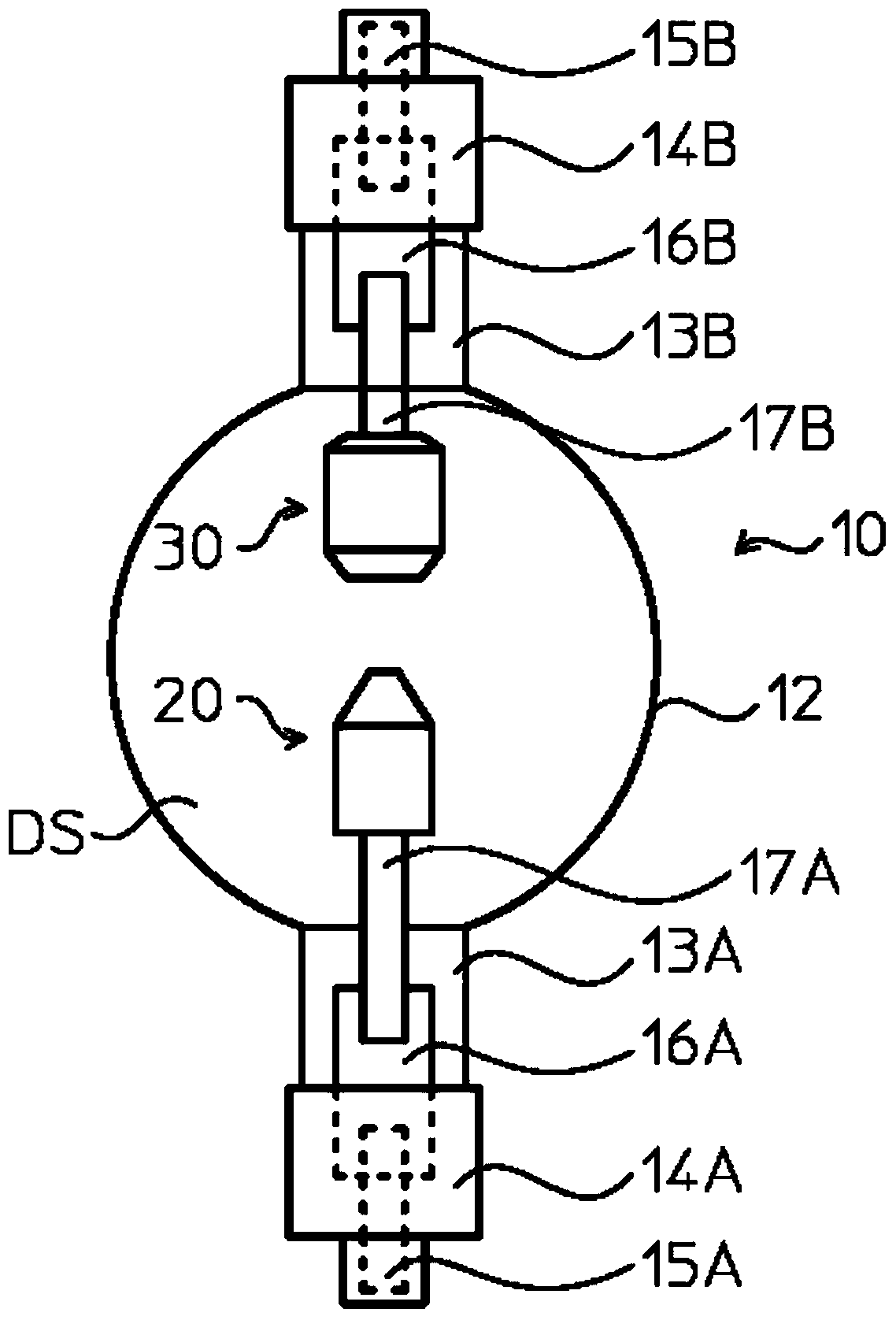

[0015] figure 1 It is a top view schematically showing the short-arc discharge lamp of the first embodiment.

[0016] The short-arc discharge lamp 10 is a discharge lamp that can be used as a light source of a pattern forming exposure device (not shown), and includes a discharge tube (light emitting tube) 12 made of transparent quartz glass. In the discharge tube 12, the cathode 20 and the anode 30 are arranged facing each other with a predetermined interval therebetween.

[0017] On both sides of the discharge tube 12, sealing tubes 13A, 13B made of quartz glass are provided integrally with the discharge tube 12 so as to face each other, and both ends of the sealing tubes 13A, 13B are sealed by caps 14A, 14B. Here, the discharge lamp 10 is arranged along the vertical direction so that the anode 30 is on the upper side and the cathode 20 is on the lower side.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com