Counter electrode for dye-sensitized solar cell and preparation method thereof

A solar cell and dye sensitization technology, applied in the field of solar cells, can solve the problems of complex synthesis process and high cost, and achieve the effects of wide sources, low production cost, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

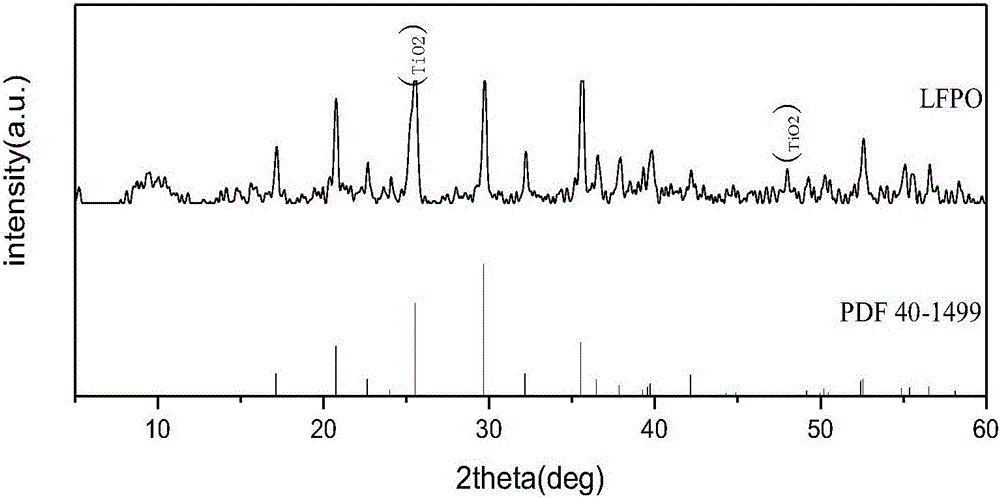

[0026] 1. Preparation of LiFePO 4 Base counter electrode paste:

[0027] 2 g of commercial battery-grade LiFePO 4 (the massfraction of carbon element is less than 0.2%), 0.2g particle diameter is the nano-titanium dioxide of 25nm, 1g ethyl cellulose ethanol solution and 4ml terpineol are mixed and stirred evenly, and mixed material is through QM-3B type high-speed ball mill with 1200 revs / Grinding for 2 hours at a speed of 10 minutes to obtain uniform and viscous LiFePO 4 base counter electrode paste.

[0028] 2. Prepare the counter electrode:

[0029] Clean FTO (doped with fluorine SnO2 Transparent conductive glass) two ends stick 3M adhesive tape, be fixed on the platform, film thickness is controlled by the number of layers of 3M adhesive tape, all is single-layer 3M adhesive tape among the present invention. First LiFePO prepared in step 1 4 The base-counter electrode slurry is dropped on the conductive surface of FTO, and the slurry is scraped back and forth by scra...

Embodiment 2

[0033] 1. Preparation of LiFePO 4 Base counter electrode paste:

[0034] 4 g of commercial battery-grade LiFePO 4 (the mass fraction of carbon element is less than 0.2%), 0.3g particle diameter is the nano-titanium dioxide of 25nm, 1.5g ethyl cellulose ethanol solution and 6ml terpineol are mixed and stirred evenly, be placed in ball-milling jar ball-milling 1.5h, obtain uniform LiFePO 4 base counter electrode paste.

[0035] 2. Prepare the counter electrode:

[0036] LiFePO 4 The base-counter electrode paste is scraped and coated on a clean ITO (indium tin oxide semiconductor transparent conductive glass), and the subsequent steps are the same as in the first embodiment.

Embodiment 3

[0038] 1. Preparation of LiFePO 4 Base counter electrode paste:

[0039] 6 g of commercial battery-grade LiFePO 4 (the mass fraction of carbon element is less than 0.2%), 0.4g of nano-titanium dioxide with a particle size of 25nm, 2g of ethyl cellulose ethanol solution and 8ml of terpineol are mixed and stirred evenly, and placed in a ball mill jar for ball milling for 1.5h to obtain a uniform LiFePO 4 base counter electrode paste.

[0040] 2. Prepare the counter electrode:

[0041] LiFePO 4 The base-counter electrode slurry is scraped and coated on clean AZO (aluminum-doped zinc oxide (ZnO) transparent conductive glass), and the subsequent steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com