Influence analytical method for identifying load error of static-pressure rotary table and analyzing influence of load error on machining error of machine tool

A technology of static pressure turntable and load error, which is used in computer control, instruments, simulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

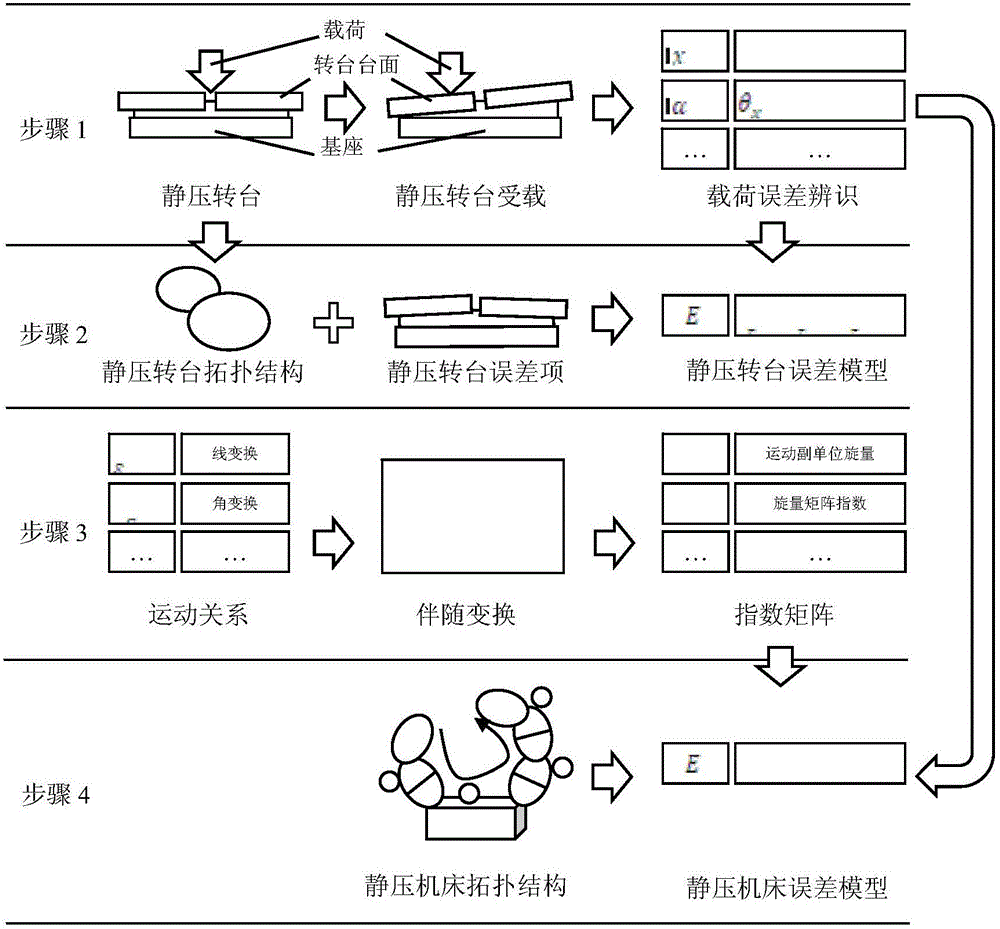

Method used

Image

Examples

Embodiment Construction

[0060] Calculation example: Taking CNC gantry mobile turning and milling heavy machine tool as an example

[0061] Step 1: Deduce the load error model of the static pressure turntable based on the theory of fluid mechanics

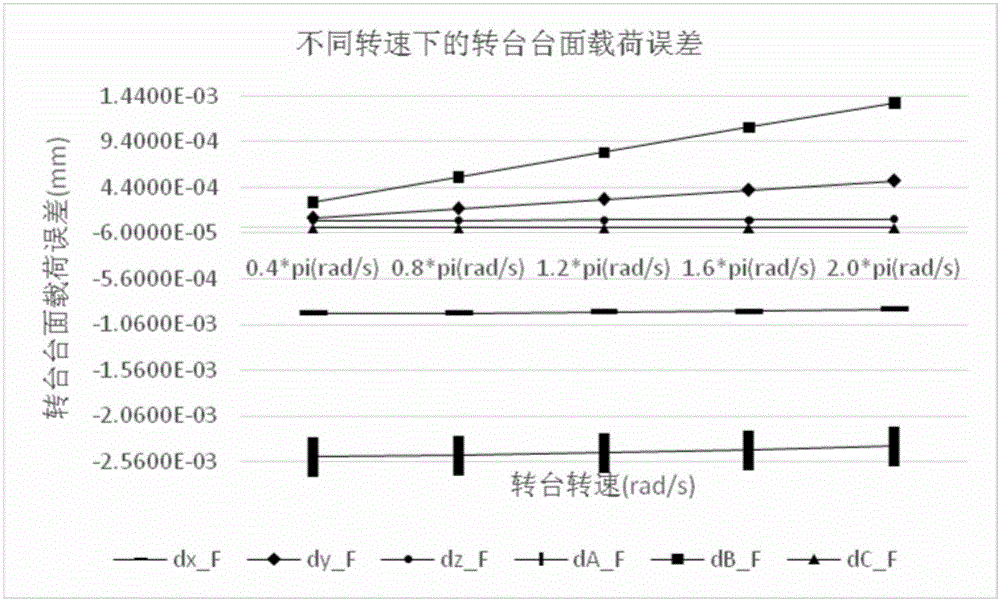

[0062] Starting from the consideration of the influence of the load error of the machine tool, the identification of the load error of the static pressure turntable table derived by means of the N-S equation and the thin film hypothesis theory is given; the load error model of the static pressure turntable is given based on the multi-body theory, and the load error is calculated and analyzed The influence on the error of the turntable, the results show that as the rotation speed of the turntable increases, the error in the Z direction of the turntable decreases, and the errors in the X and Y directions increase; with the increase of the load force or loading radius, the errors in all directions of the turntable will increase.

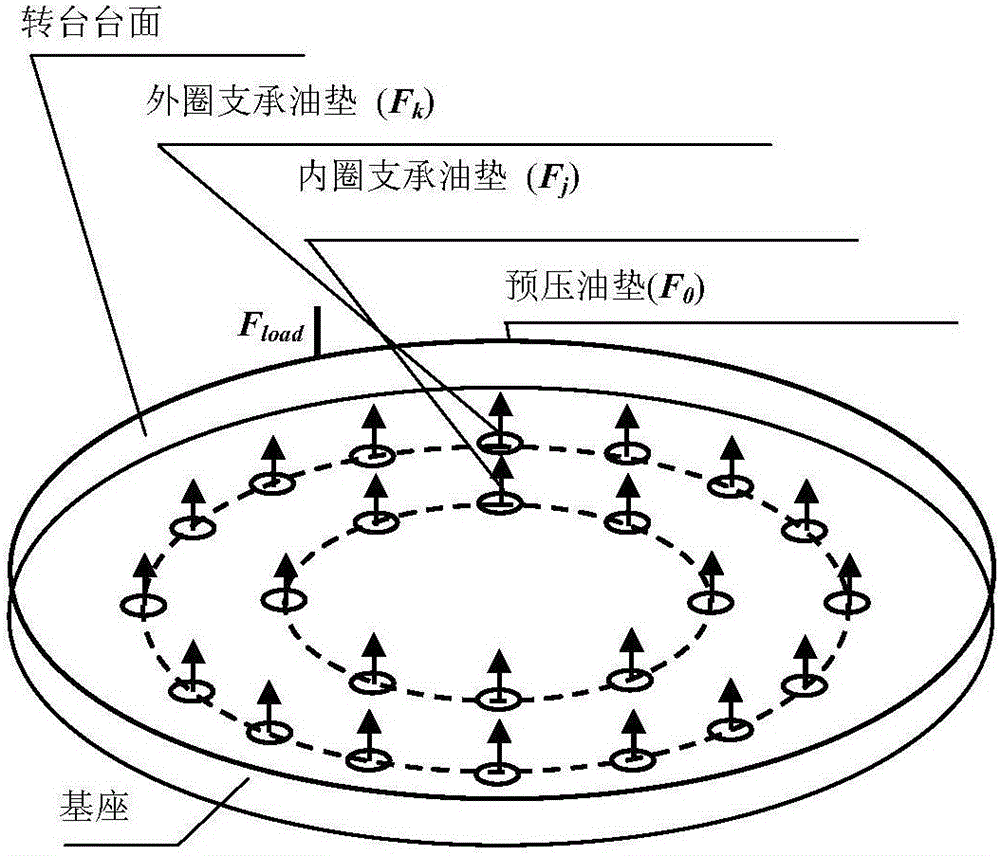

[0063] Step 1.1 Identify th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com