Method for detecting gas line defect of glass tube

A detection method, glass tube technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as difficult production line rhythm, coordination, eye fatigue of operators, etc., to ensure physical health and product quality , to avoid the effect of eye fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

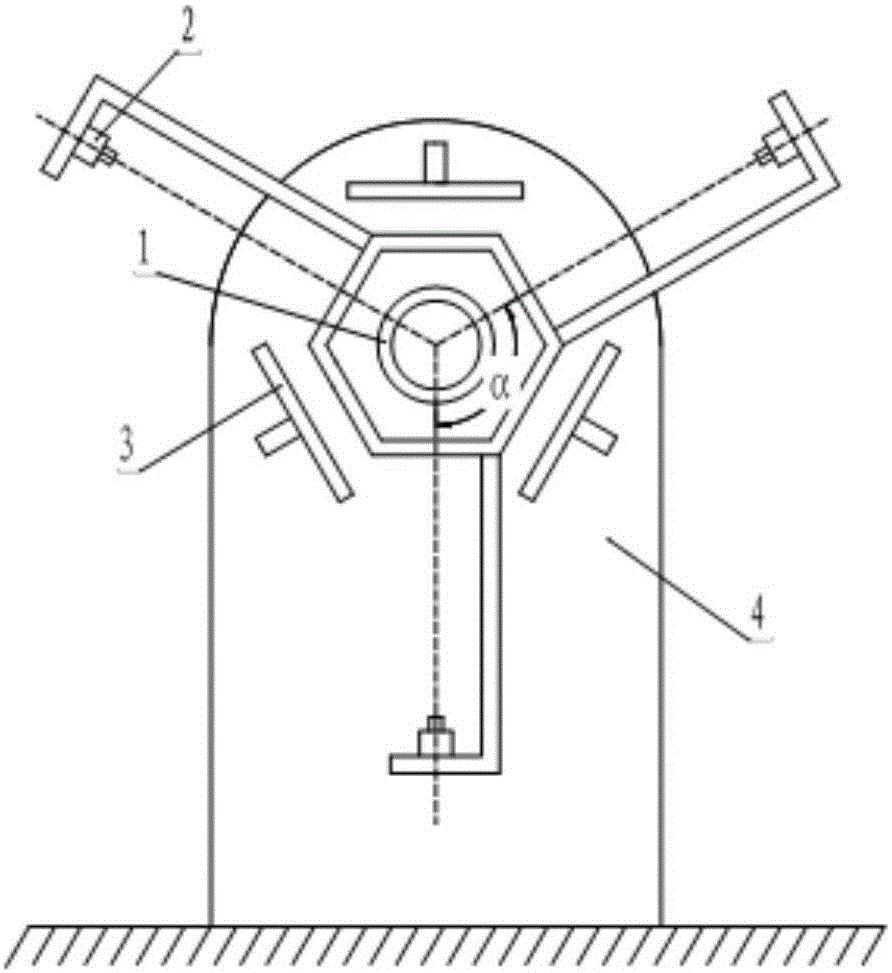

[0021] see figure 1 , figure 2 , the detection method of the gas line defect of the glass tube according to the present invention uses three groups of camera equipment arranged on the glass tube pulling line to take pictures of the glass tube to collect all-round image information of the glass tube product after thermal drawing, The processor analyzes and judges the quality status of glass tube products, and then the control system promptly and accurately eliminates unqualified products to ensure the product quality of the bottle making process.

[0022] A specific embodiment of the present invention is aimed at The detection of the air line in the glass tube product. At this time, the pulling speed of the glass tube pulling line is 70mm / s. The specific operation steps are as follows:

[0023] a. Three groups of camera equipment 2 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com