Miniaturized wet-heat type abrasion testing machine

A wear test, damp heat technology, applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of inability to detect rubber, can not truly reflect the use situation, great differences, etc., achieve high practicability, optimize resistance to damp heat wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

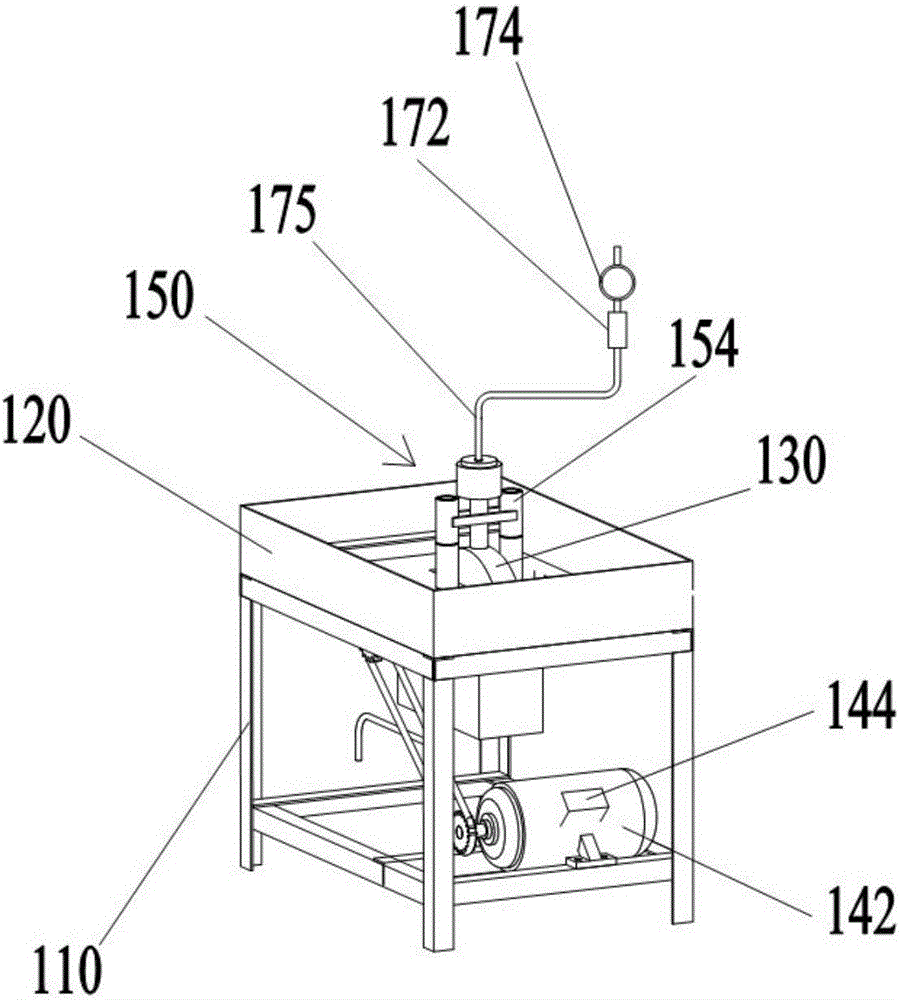

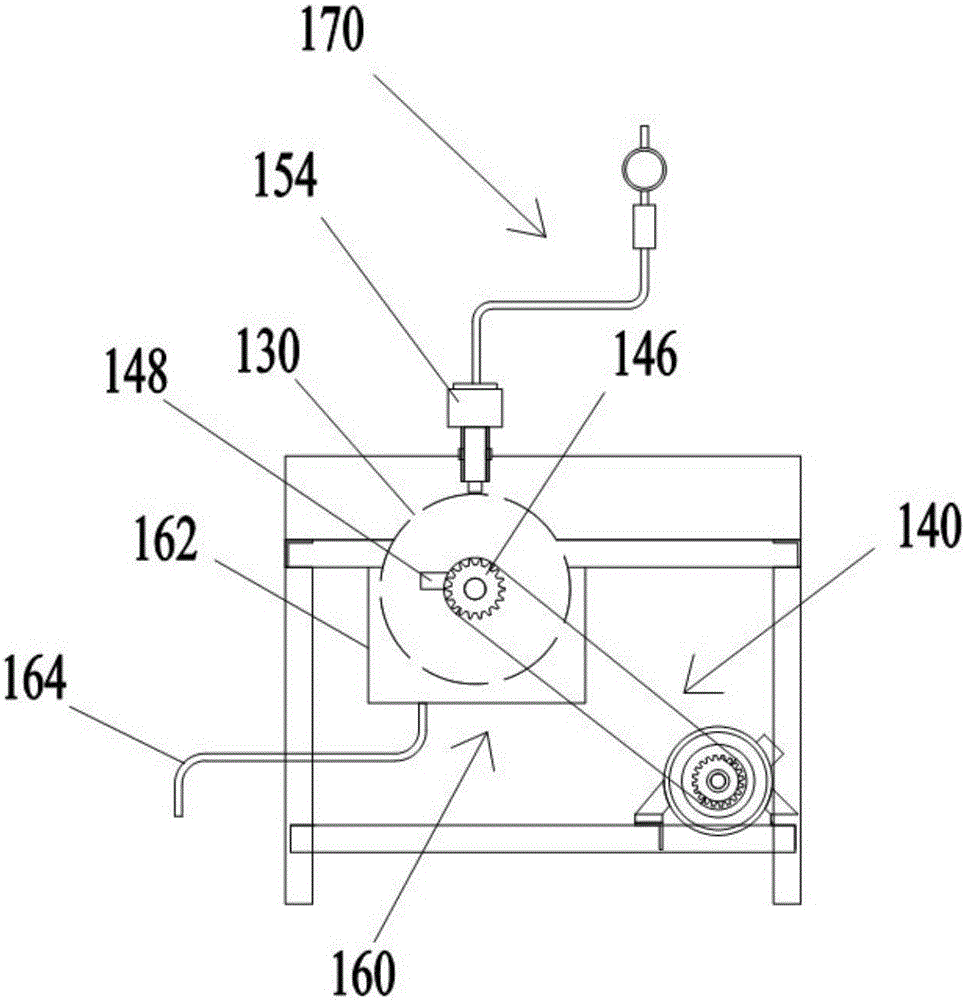

[0023] Such as Figure 1 to Figure 2 As shown, the miniaturized wet heat abrasion testing machine provided by the present invention includes a bracket 110, an abrasive grinding wheel 130, a protective cover 120 and a driving device 140, and also includes a constant pressure device 150 for providing a constant pressure for the sample, and a water collection device. 160 and the damp heat supply device 170 used to ensure the constant temperature experiment of the sample, the protective cover 120 is installed on the top of the bracket 110, the abrasive grinding wheel 130 and the driving device 140 are installed in the bracket 110, and the constant pressure device 150 is arranged directly above the abrasive grinding wheel 130 , the water collection device 160 is arranged directly below the grinding wheel 130, and the constant pressure device 150 is provided with a mounting hole for installing the damp heat supply device 170, and the duckbill nozzle 175 at the end of the damp heat su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com