Motor bearing online monitoring and intelligent early warning system

A technology of motor bearing and early warning system, which is used in mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as affecting motor performance, failing to notify operators in time, and not performing bearing monitoring and early warning. , to achieve the effect of improving early warning and processing speed, improving maintenance efficiency, and improving early warning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

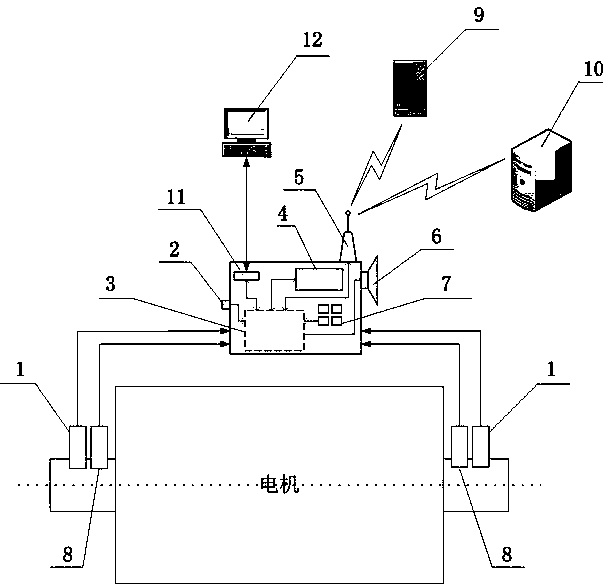

[0027] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0028] like figure 1 As shown, the front and rear bearings of the motor have a bearing temperature sensor (1) and a bearing noise sensor (8) respectively. The four sensors are penetrated through the drilling holes of the motor end cover and adhere to the outer ring of the bearing. The temperature and noise data are sent to the measurement analysis module (3). The ambient temperature sensor (2) measures the ambient temperature and is connected with the measurement and analysis module (3). The measurement and analysis module (3) subtracts the temperature of the outer ring of the bearing from the ambient temperature to obtain the real-time temperature rise of the outer ring of the bearing.

[0029] The measurement and analysis module (3) analyzes the temperature rise and temperature change trend of the outer ring of the bearing, and combines the data of the bearing noi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com