Refrigerant hydrate circulating cool storage system

A hydrate and refrigerant technology, which is applied to machines, refrigerators, and air conditioning systems that use refrigerant evaporation, can solve problems such as the increase in energy consumption due to the gap between urban power consumption peaks and valleys, and solve the problem of large equipment and energy loss. Problems, considerable effect of cold storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

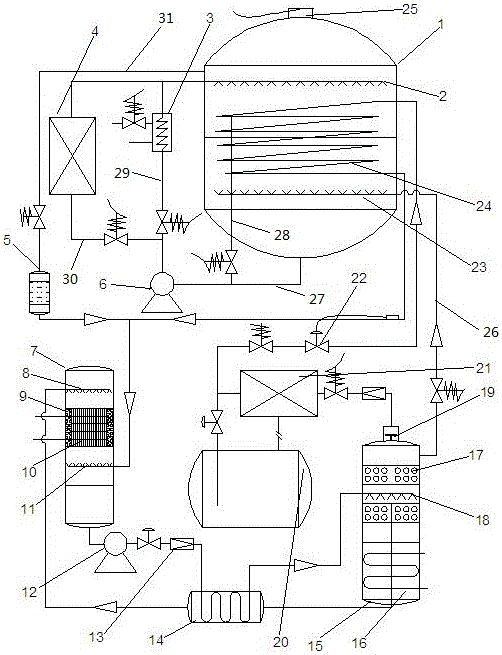

[0022] As shown in the figure, a refrigerant hydrate circulating cold storage system includes a hydrate reaction tank 1, an absorber 7, a solution pump 12, a generator 15, a condenser 21, and DMF solvent and refrigerant R134a running in the entire system The formed mixed liquid, wherein, the upper and lower parts of the absorber 7 are respectively provided with a solvent spray nozzle 8 and a refrigerant hole tube 11, and the DMF solvent and refrigerant R134a pass through the solvent spray nozzle 8 and the refrigerant hole tube respectively 11 After spraying, a mixed solution is formed at the filler layer I9 in the absorber 7, and is pumped into the generator 15 by the solution pump 12, and sprayed on the filler layer II17 in the generator 15 by the mixed solution nozzle 18. The generator 15 is provided with a heating device 16 for heating the mixed solution after spraying, so that the refrigerant R134a in the mixed solution evaporates to generate R134a vapor, and the vapor pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com