Vertical type shell-and-tube heat exchanger

A shell-and-tube heat exchanger, vertical technology, applied in the direction of heat exchanger duct, heat exchanger type, heat exchanger shell, etc. The baffle is easy to accumulate liquid and other problems, so as to achieve the effect of good overall heat transfer coefficient and comprehensive performance, long service life, and improved heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

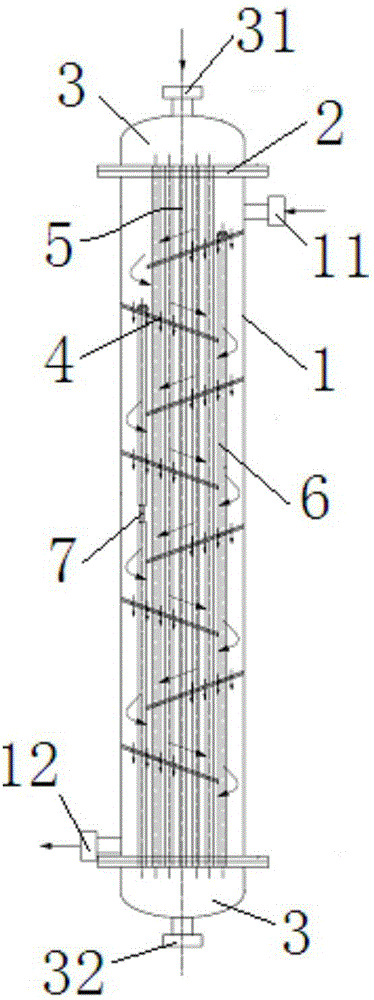

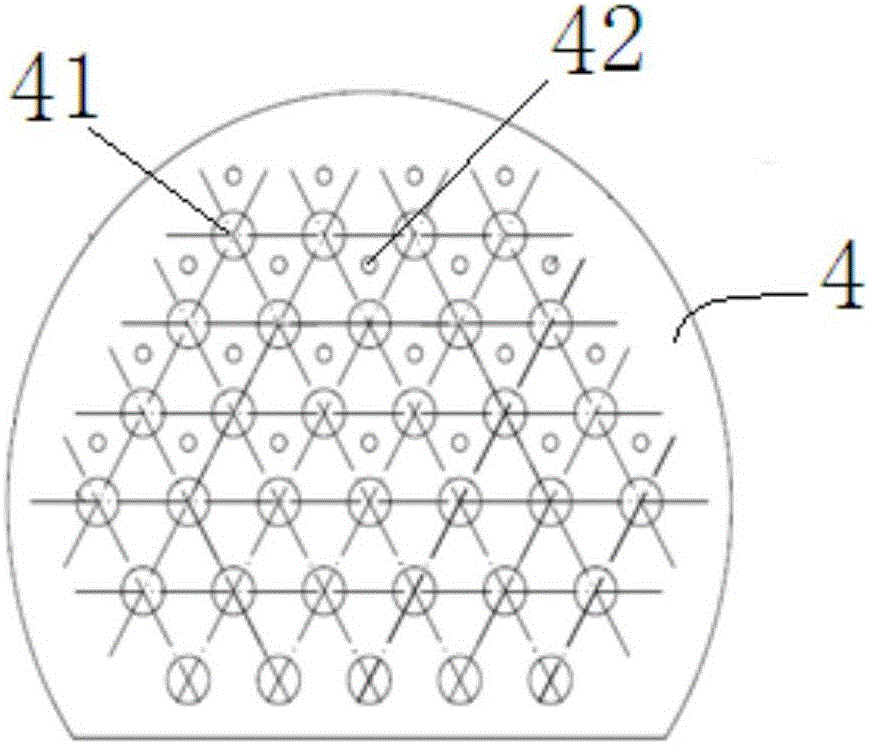

[0015] Such as figure 1 As shown, the present invention proposes a vertical shell-and-tube heat exchanger, which includes a vertically arranged shell 1, and the upper and lower ends of the shell 1 are respectively connected to a tube box 3 through a tube plate 2. A shell-side inlet pipe 11 is arranged on one side of the upper end of the shell 1 , and a shell-side outlet pipe 12 is arranged on one side of the lower end of the shell 1 . A pipe-side inlet pipe 31 is arranged on the top of the pipe box 3 at the upper end, and a pipe-side outlet pipe 32 is arranged at the bottom of the pipe box 3 at the lower end. A plurality of baffles 4 with notches are arranged alternately at intervals inside the housing 1 (such as figure 2 shown). Two adjacent baffles 4 are fastened to the side walls on different sides of the housing 1 , and fluid communication cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com