Device used for rapidly drying product formed through hard alloy

A cemented carbide and fast drying technology, which is applied in drying, drying machines, heating devices, etc., can solve the problems of heating and vacuuming, long drying time, and long drying time in the shade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

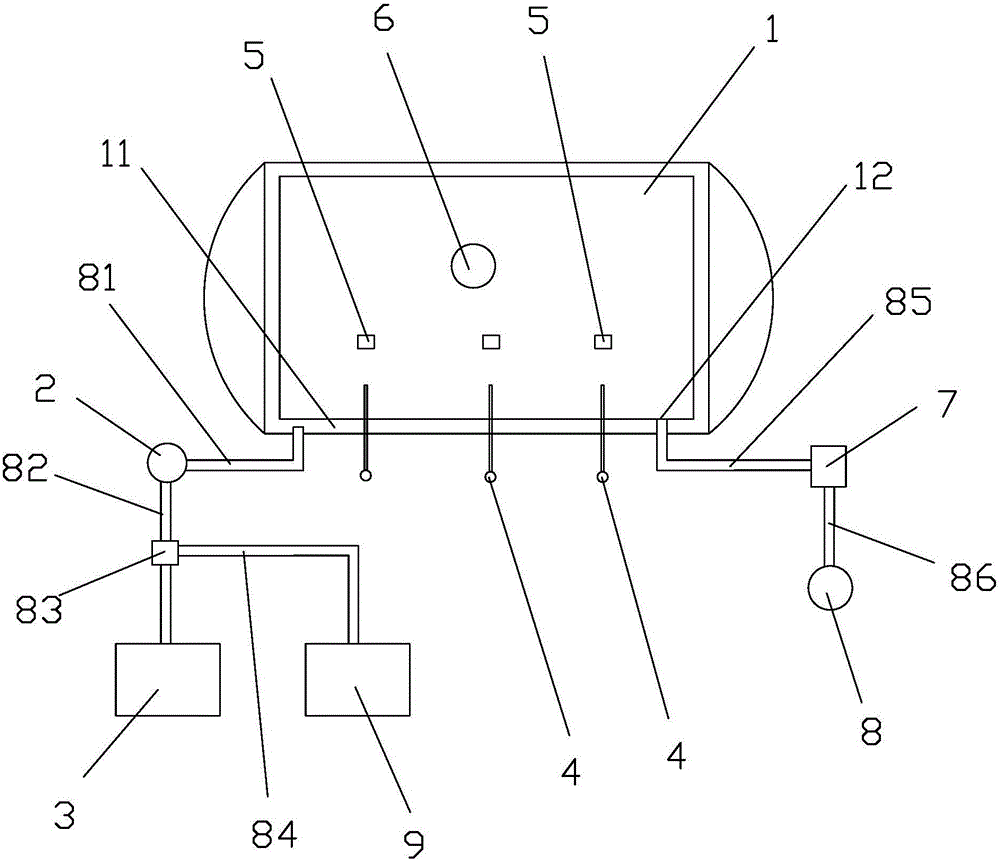

[0016] A device for quickly drying hard alloy molded products according to the present invention includes a furnace body 1 capable of being closed, and a water bath chamber 11 is arranged in the furnace wall of the furnace body, and the water bath chamber 11 is connected by a water pump 2 A hot water tank 3, so that the hot water in the hot water tank 3 can be sent into the inner cavity of the furnace body 1, so as to realize the water bath drying of the cemented carbide molded products put into the inner cavity of the furnace body; the inner cavity of the furnace body 1 A thermocouple 4 is respectively installed at the left, middle and right positions of the bottom of the furnace body to detect the temperature of the furnace body cavity; the body of furnace 1 is also provided with three temperature displays 5, which are connected to the furnace body 1 respectively. Three thermocouples 4 are connected in phase to display the temperature value corresponding to the thermocouple 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com