A heat transfer oil roof radiant heating system with fresh air preheating function

A technology of fresh air preheating and radiant heating, applied in heating systems, heating methods, household heating, etc., can solve the problems of high boiling point and low freezing point of heat transfer oil, and achieve high surface temperature, rapid temperature rise, and thermal comfort Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

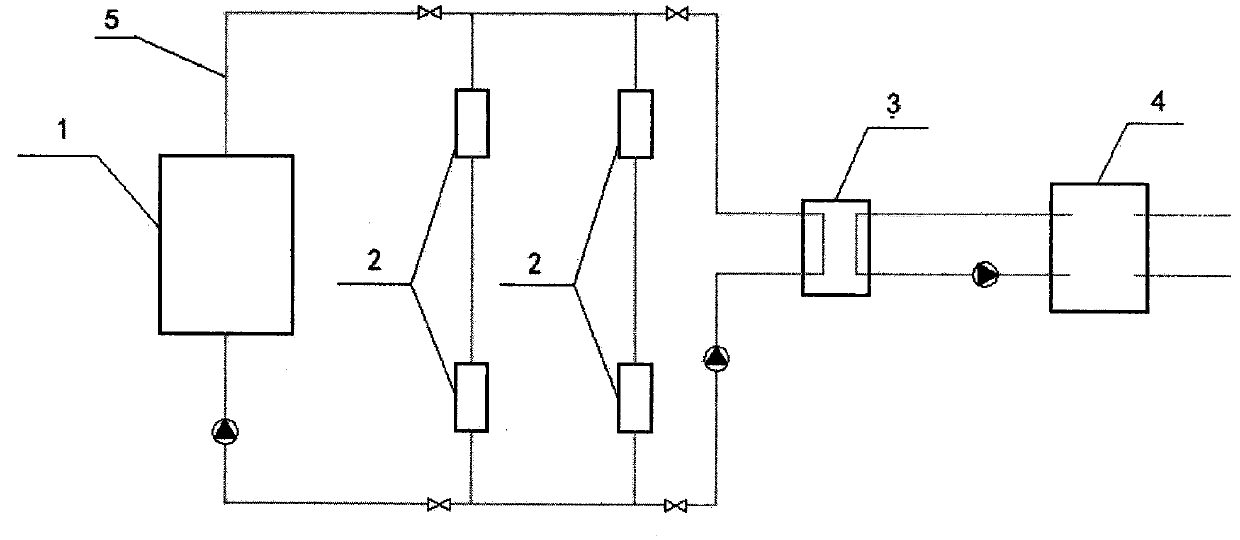

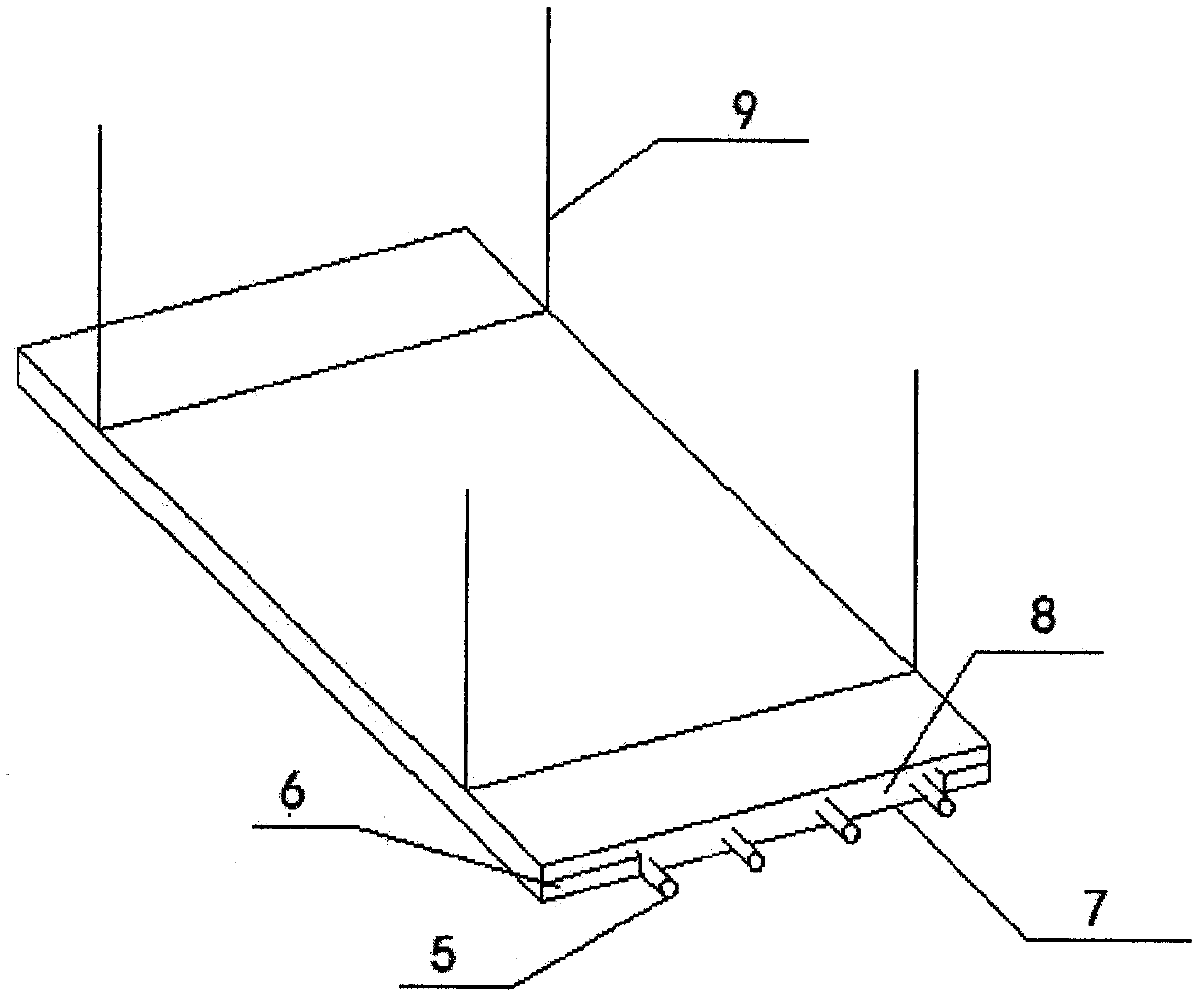

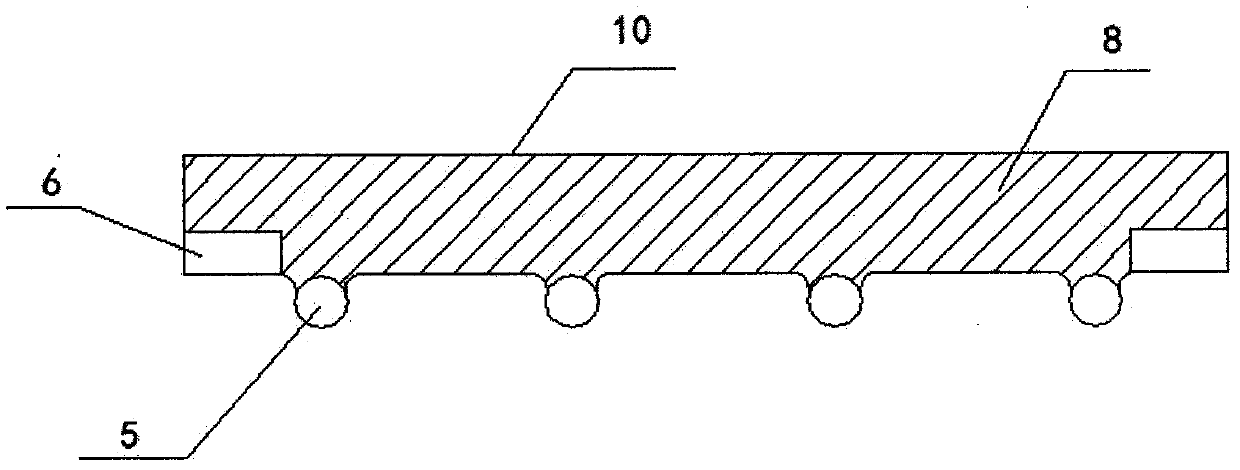

[0027] Such as figure 1 , figure 2 with Figure 5 As shown, a heat transfer oil roof radiant heating system with fresh air preheating function provided by the embodiment of the present invention includes: heat transfer oil furnace 1, oil pump, multiple heat transfer oil radiation plates 2, multiple control valves and heat transfer oil pipelines 5 , the oil pump is installed on the heat-conducting oil furnace 1, and a plurality of control valves are distributed on the heat-conducting oil pipeline 5, the heat-conducting oil furnace 1 communicates with the heat-conducting oil pipeline 5 through the oil pump and a plurality of control valves, and the heat-conducting oil pipeline 5 passes through a plurality of heat-conductin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com