Energy-saving efficient garbage incinerator

A waste incinerator, energy-saving technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problem of high processing cost, achieve the effect of reducing equipment investment, increasing temperature, and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

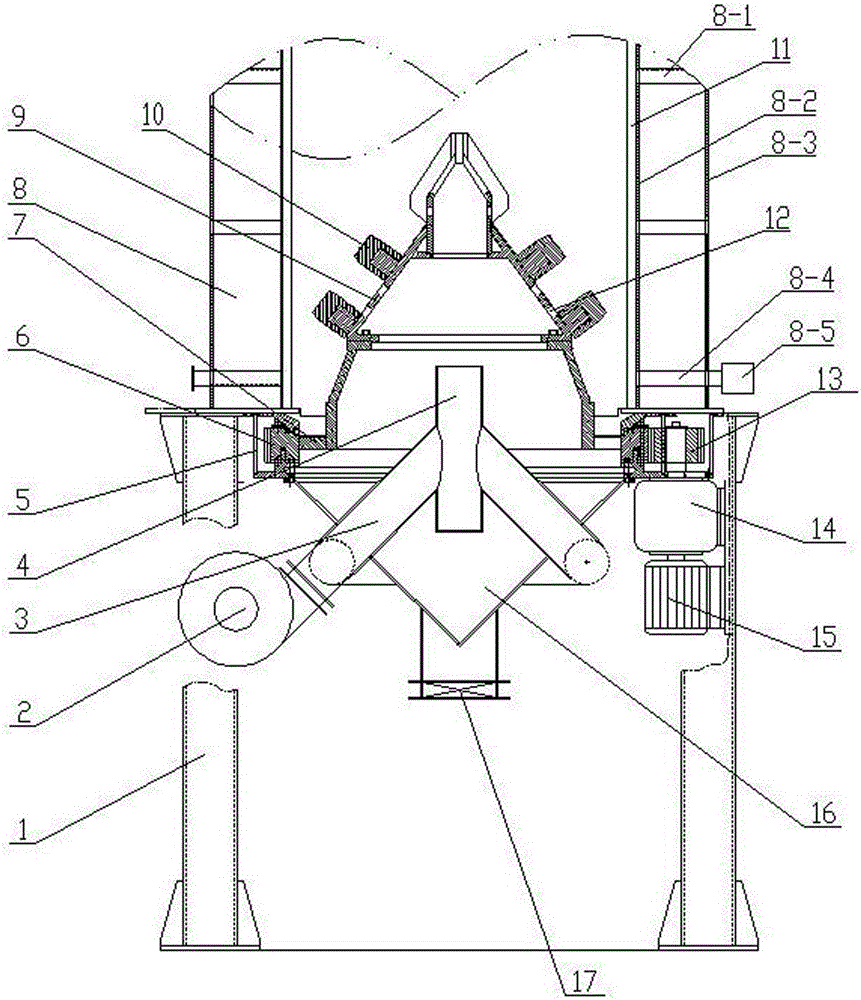

[0021] Such as figure 1 As shown, the energy-efficient high-efficiency waste incinerator of the present invention includes a furnace body 8 , and a base 1 for supporting the furnace body 8 is provided at the bottom of the furnace body 8 . A support 5 is provided at the bottom of the inner chamber of the furnace body 8 . The support 5 is ring-shaped with a rectangular cross-section, an annular opening running through the entire length of its circumference is processed on its inner wall, and an opening is processed on its outer wall. An outer ring gear 6 is arranged inside the support 5, and annular grooves are processed on the upper and lower sides of the annular opening of the support 5, and annular bosses are processed on the upper and lower end surfaces of the outer ring gear 6, and the annular bosses are in the form of The sliding shape is placed in the annular groove, and balls are installed between the annular groove and the corresponding annular boss, so that the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com