One-way pressure regulating overflow valve with thrust bearing

A pressure regulating relief valve and thrust bearing technology, applied in the field of hydraulic machinery, can solve the problems of unreasonable structural design of pressure regulating relief valve, inconvenient operation and use, and increase of external leakage points, etc., and achieve easy processing, maintenance, replacement and combination Easy to use, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

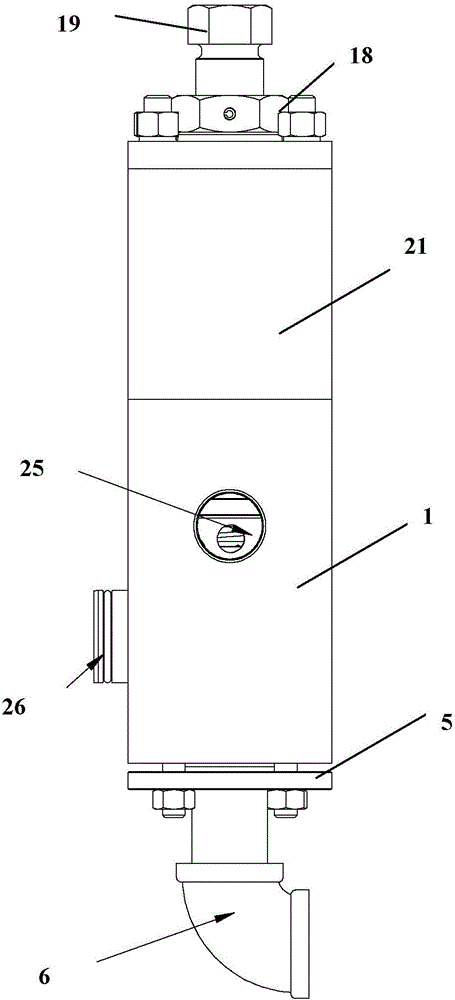

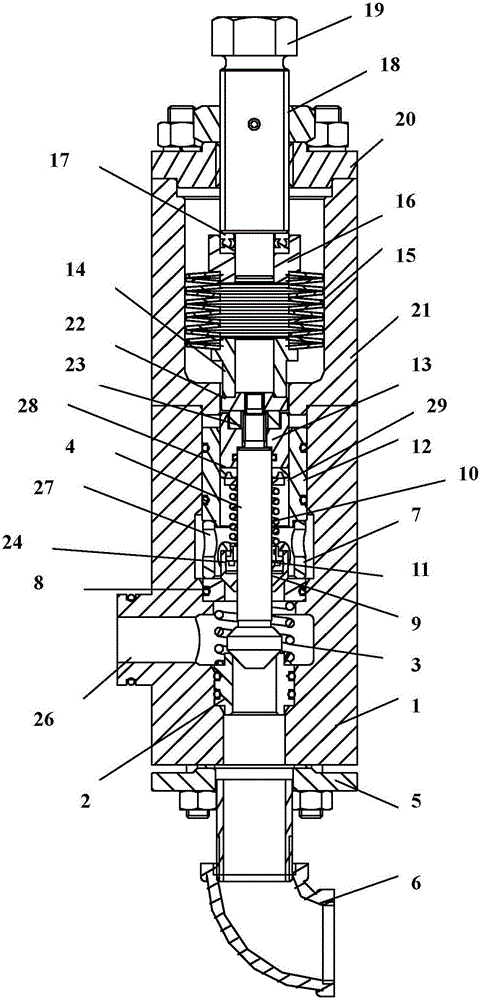

[0013] The one-way pressure regulating and relief valve with thrust bearing provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] Such as figure 1 — figure 2 As shown, the one-way pressure regulating relief valve with thrust bearing provided by the present invention includes a lower valve body 1, a relief valve seat 2, a relief valve spring 3, a valve stem 4, a lower flange 5, an elbow 6, a spacer Set 7, one-way valve seat 8, one-way valve core 9, one-way valve spring 10, pressure ring 11, bushing 12, guide sleeve 13, lower spring seat 14, disc spring 15, upper spring seat 16, thrust bearing 17 , lock nut 18, adjusting bolt 19, gland 20, upper valve body 21, lock nut 22, round nut 23, Y-shaped sealing ring 24; wherein the lower valve body 1 is a square tubular structure arranged vertically, the middle and lower sides A liquid discharge port 25 and a liquid inlet port 26 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com