Harmonic speed reducer of improved structure

A harmonic reducer and integrated technology, applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of short life, high manufacturing cost, small bearing capacity, etc., and achieve improved fatigue life and simple processing , The effect of reducing the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

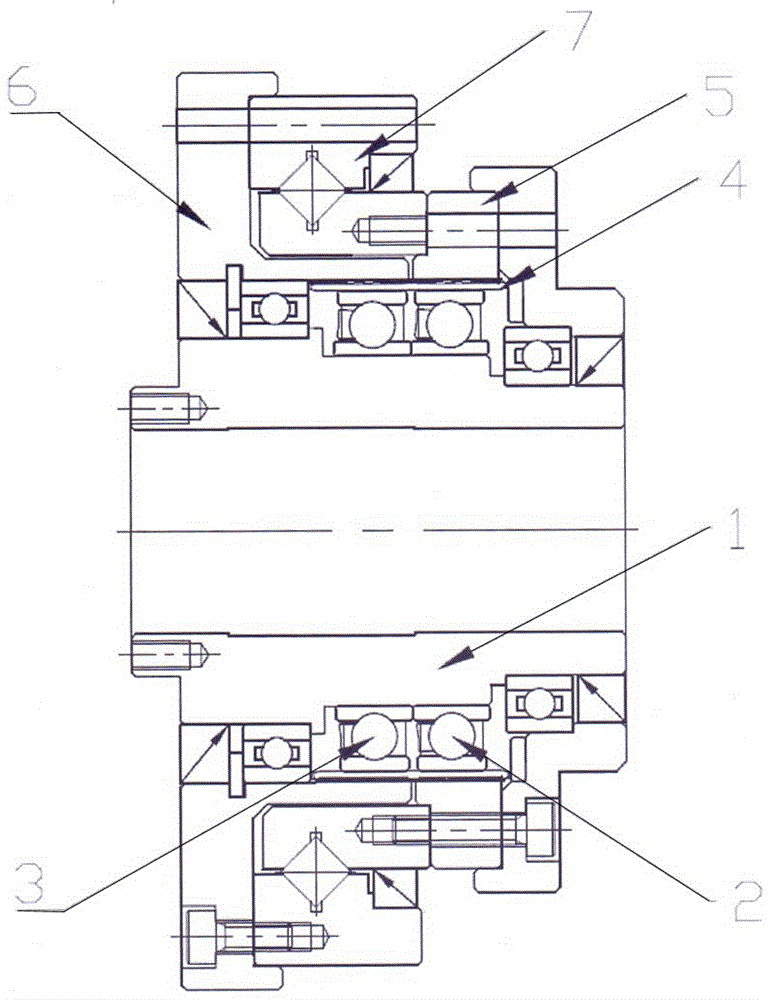

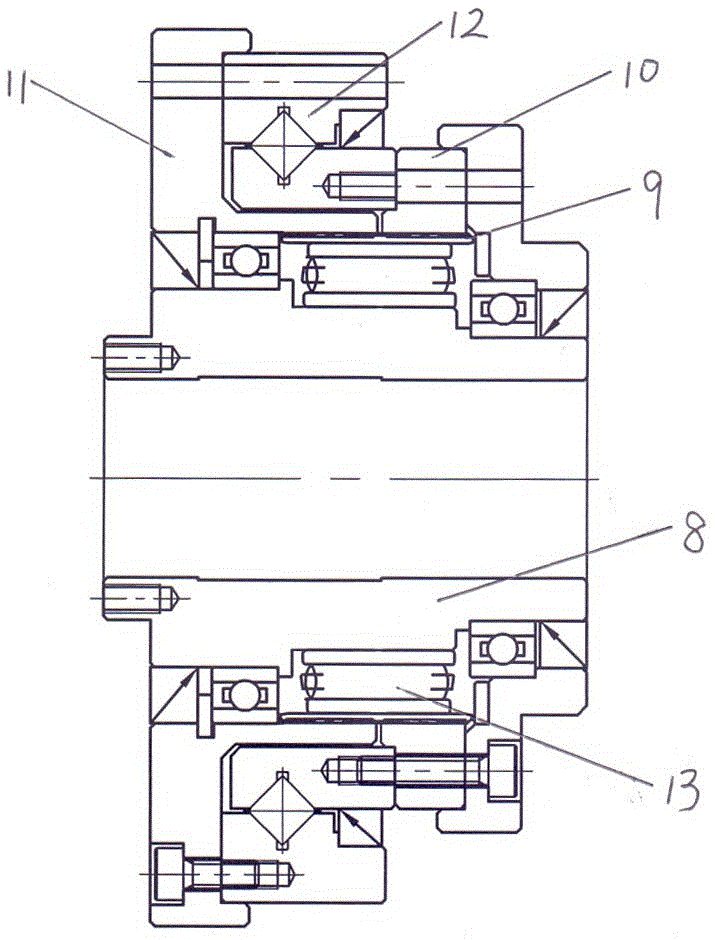

[0020] A harmonic reducer with an improved structure, including a cross roller bearing 12, an elliptical wave generator 8, a flexible bearing 13 mounted on the elliptical wave generator, a circular flexible wheel 9 installed on the flexible bearing, and an outer flexible wheel Rigid wheels 10, 11; the flexible bearing is a cylindrical roller flexible bearing.

[0021] The cylindrical roller flexible bearing is one of the following structural forms:

[0022] (1) There are inner ring and outer ring; the inner ring is set on the ellipse of the wave generator; the outer ring is set on the inner wall of the flexible spline;

[0023] (2) Only the outer ring is reserved in the inner ring and the outer ring, the metal properties of the wave generator are consistent with the inner ring, the inner ring and the wave generator are integrated, and the ellipse of the wave generator is used as the inner raceway of the cylindrical roller;

[0024] (3) Only the inner ring is kept in the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com