A synchronous hydraulic system and crane

A hydraulic system and synchronous component technology, applied in the hydraulic field, can solve problems such as out-of-control synchronous movement of two cylinders, increased cost, and reduced system reliability, and achieve the effects of avoiding large overshoot, reducing design cost, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

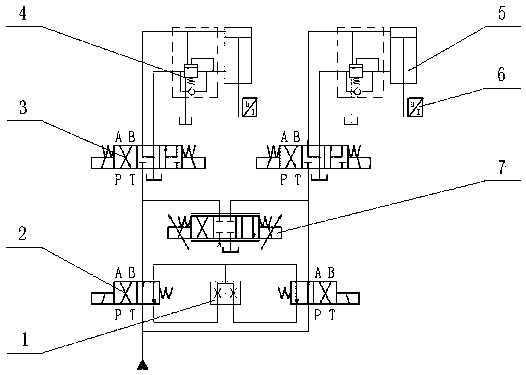

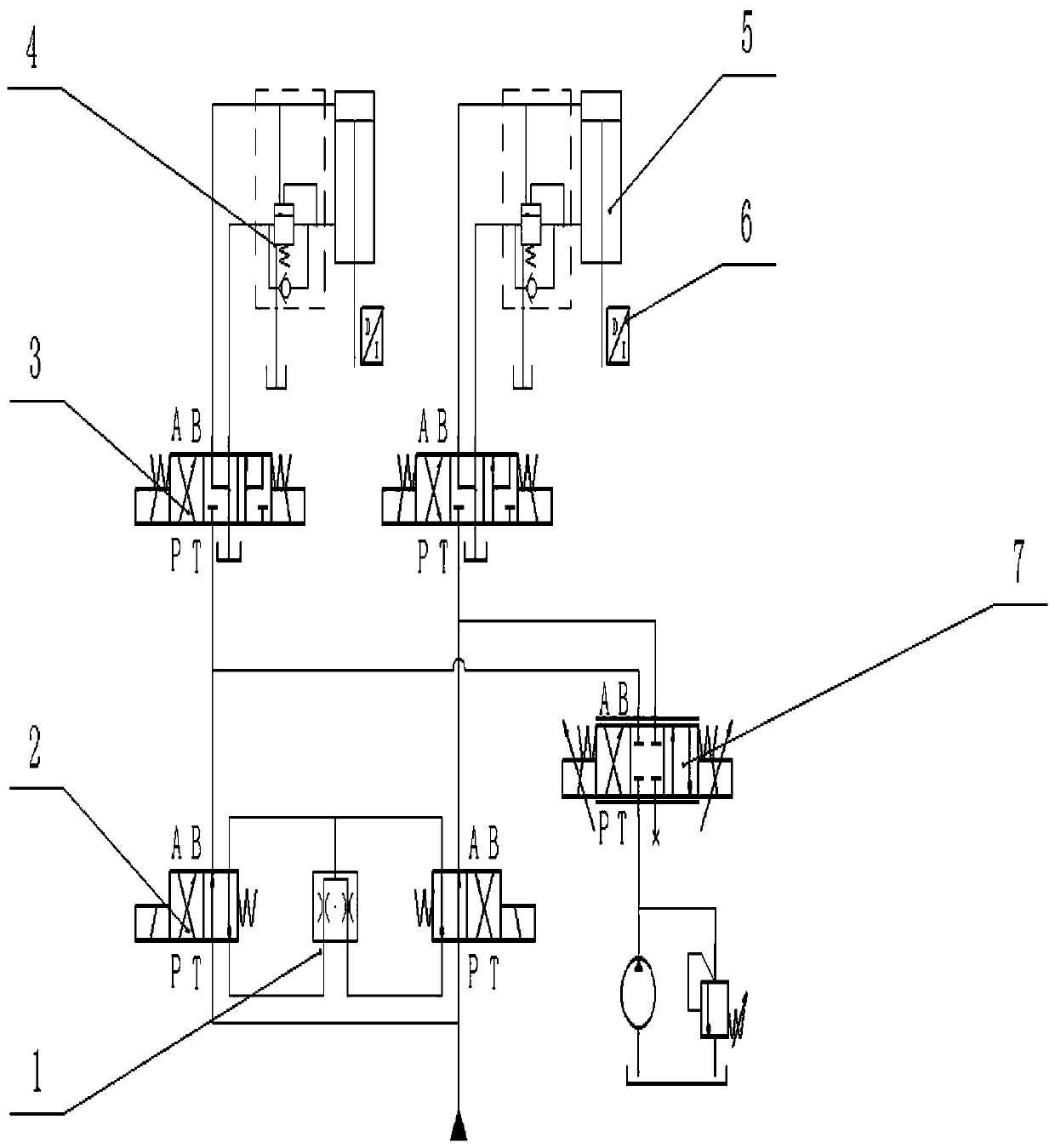

[0030] This embodiment provides a synchronous hydraulic system, including an oil pump, a control element, a first actuator, and a second actuator; the control element includes a primary control element for coarse flow adjustment and a secondary control element for fine flow adjustment ; The primary control element includes a first reversing valve, a second reversing valve, and a flow-dividing and converging valve; the secondary control element includes a third reversing valve, a fourth reversing valve, and a proportional reversing valve; The two working oil ports of the valve are respectively connected in parallel with the oil inlet ports of the third reversing valve and the fourth reversing valve;

[0031] The primary control element is connected with the oil pump; the oil outlet of the oil pump is selectively communicated with the oil inlet of the synchronous element or the oil inlet of the third directional valve through the first reversing valve; the oil outlet of the oil p...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 lies in the connection mode of the two proportional reversing valves 7 and the difference of the synchronous components. Such as figure 2 As shown, the working oil port of proportional reversing valve 7 is respectively connected with the oil inlet port of the third reversing valve and the oil inlet port of the fourth reversing valve, the oil port T is cut off, and the oil port P is connected to the charge pump; in this embodiment The middle synchronous element is a synchronous motor (not shown in the figure).

[0051] When performing synchronous control of oil cylinders, the difference between this embodiment and Embodiment 1 lies in the fine adjustment method of the secondary flow rate, and this embodiment compensates the synchronization error by means of oil replenishment.

[0052] In the following, when the two oil cylinders are lowered, the speed of the first oil cylinder is slightly faster as an example to illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com