Gypsum-based waterproof, fireproof, containment and heat-insulation system for steel-structure house and preparation method for same

A thermal insulation system and gypsum-based technology, which is applied in the field of gypsum-based water-resistant and fire-resistant enclosure thermal insulation systems and preparations for steel structures, can solve the problems of poor thermal insulation effect, poor fire resistance, high resources, etc., and achieve high water resistance and physical and mechanical properties , reduce the amount of cement, the effect of simple forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

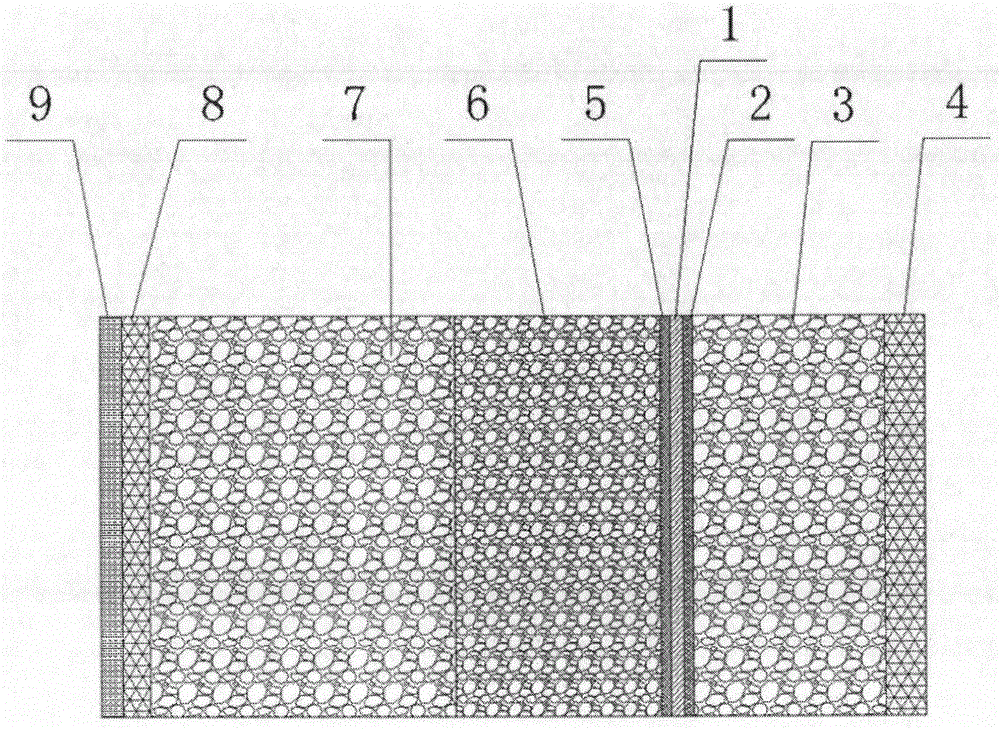

[0036] like figure 1 As shown in the figure, a steel structure residential gypsum-based water-resistant fireproof enclosure thermal insulation system includes a base material layer 1, an external interface layer 2, an external thermal insulation layer 3, an external protective layer 4, an internal interface layer 5, an internal fireproof layer 6, and an internal thermal insulation layer. Layer 7, inner protective layer 8, interior surface layer 9. The outer side of the base material layer 1 is provided with an outer interface layer 2, the outer side of the outer interface layer 2 is provided with an outer thermal insulation layer 3, and the outer side of the outer thermal insulation layer 3 is provided with an outer protective layer 4; There is an inner interface layer 5, the inner interface layer 5 is internally provided with an inner fireproof layer 6, the inner side of the inner fireproof layer 6 is provided with an inner thermal insulation layer 7, and the inner side of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com