Stress absorption band preparing and paving device

A stress-absorbing belt and preparation device technology, which is applied in construction, road, road repair, etc., can solve the problem that it is difficult to ensure the thickness and flatness of the stress-absorbing belt, affect the integration of upper and lower stress-absorbing materials, and cannot solve the problem of integrating the stress-absorbing belt to achieve the effect of simple structure, simple control and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

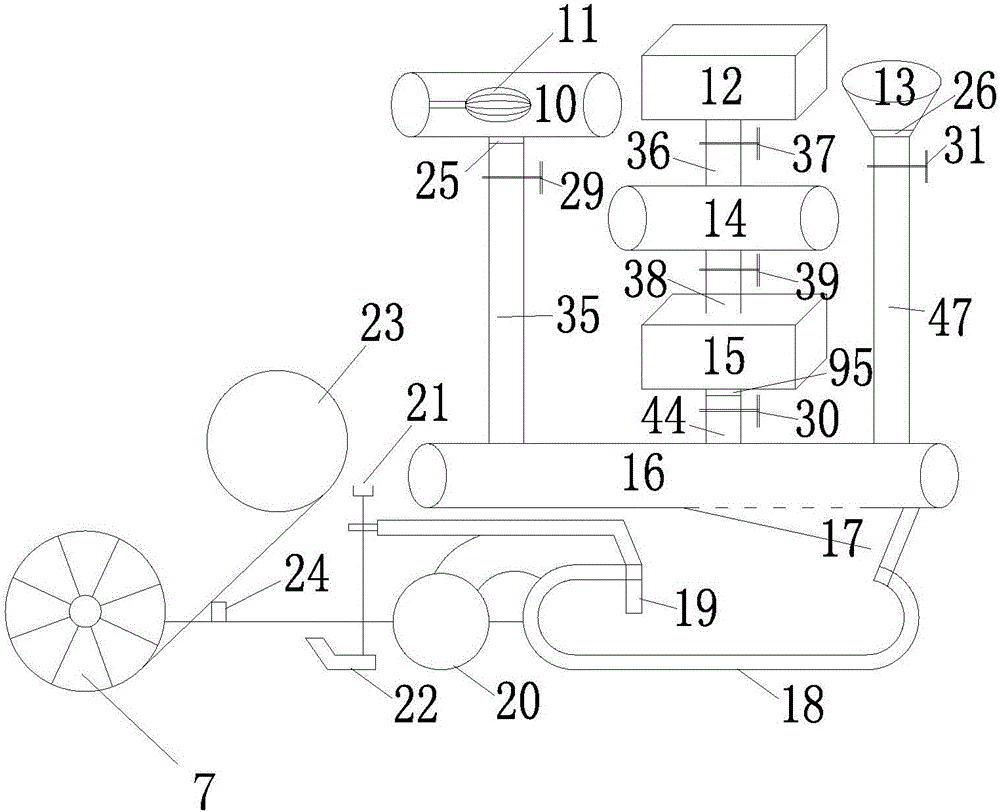

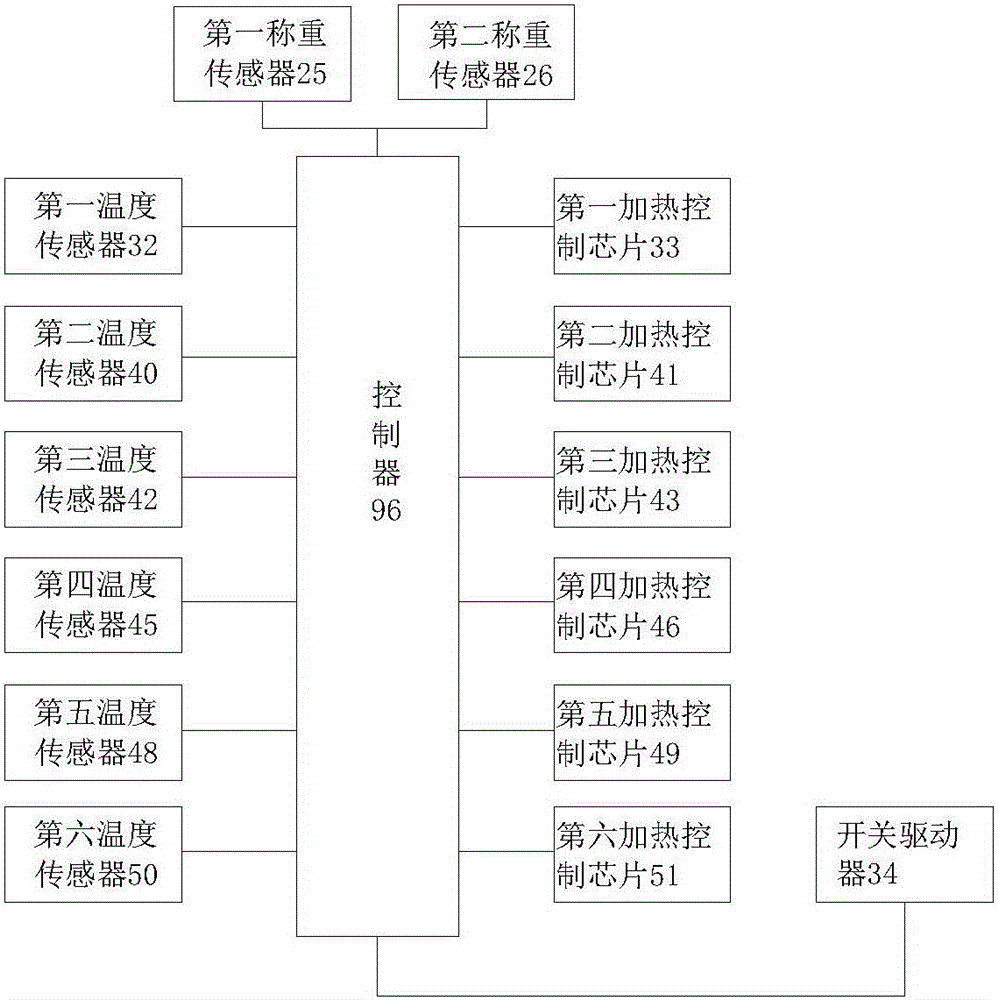

[0024] Such as figure 1 as well as figure 2As shown, the present invention provides a kind of stress absorbing tape preparation and paving device, and this device comprises stress absorbing tape compound preparation device, the paving device of stress absorbing tape compound, polyester fiberglass cloth paving device and respectively with The data acquisition and control device connected to the stress-absorbing zone mixture preparation device and the stress-absorbing zone mixture paving device; the stress-absorbing zone mixture preparation device includes asphalt heating treatment device, aggregate processing device, mineral powder processing device and stirring pot 16. The asphalt heating treatment device, aggregate processing device and mineral powder processing device are respectively connected with the stirring pot 16; the paving device for the stress-absorbing belt mixture includes a hopper 18, a feeder 19, a thickness adjustment screw 21, and a spiral spreader 20 and sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com