Isostatic press oil for sinter molding of rare earth magnet steel, and preparation method of isostatic press oil

A technology of sintering molding and isostatic pressing, which is applied in the petroleum industry, lubricating compositions, etc., can solve problems such as low viscosity index, dark oil color, and poor fluidity, and achieve low viscosity, fine and soft material quality, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

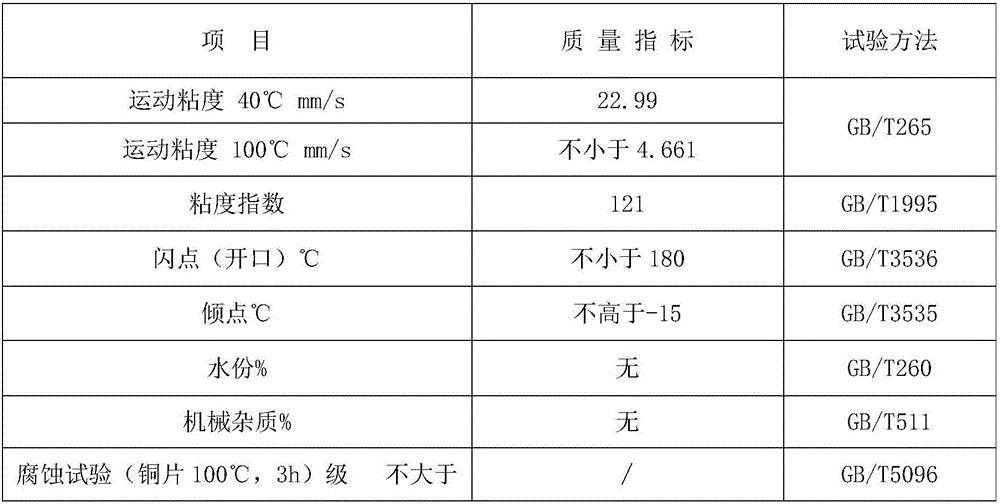

Image

Examples

Embodiment 1

[0021] A kind of isostatic pressure oil used for sintering and molding rare earth magnets, which is composed of the following raw materials in parts by weight:

[0022] White mineral oil 95, hydrogenated base oil 4, 8-hydroxyquinoline 0.02, antiwear agent 3, antifoaming agent 0.03, antioxidant 0.4, triisopropyl borate 1, flow aid 2-3, boric acid 0.07, Ethyl orthosilicate 0.2, sp-80 0.06.

[0023] Wherein, the antiwear agent is zinc dialkyldithiophosphate. The anti-foaming agent is organosiloxane. The antioxidant is 2,6-di-tert-butyl-p-cresol.

[0024] Wherein, the flow aid is composed of the following raw materials in parts by weight: 7.5 parts by weight of triethanolamine oleate, 0.2 parts by ammonium molybdate, 2 parts by weight of potassium stearate soap, and 0.6 parts by weight of ethanol;

[0025] The preparation method of described flow aid comprises the following steps:

[0026] Mix the above-mentioned absolute ethanol and triethanolamine oleate, stir evenly, add po...

Embodiment 2

[0033] A kind of isostatic pressure oil used for sintering and molding rare earth magnets, which is composed of the following raw materials in parts by weight:

[0034] White mineral oil 90, hydrogenated base oil 6, 8-hydroxyquinoline 0.01, antiwear agent 5, antifoaming agent 0.01, antioxidant 0.6, triisopropyl borate 2, flow aid 2-3, boric acid 0.04, Ethyl orthosilicate 0.1, sp-80 0.04.

[0035] Wherein, the antiwear agent is zinc dialkyldithiophosphate. The anti-foaming agent is organosiloxane. The antioxidant is 2,6-di-tert-butyl-p-cresol.

[0036] Wherein, the flow aid is composed of the following raw materials in parts by weight: 8 triethanolamine oleate, 0.1 ammonium molybdate, 3 potassium stearate soap, and 1 absolute ethanol;

[0037] The preparation method of described flow aid comprises the following steps:

[0038] Mix the above-mentioned absolute ethanol and triethanolamine oleate, stir evenly, add potassium stearate soap, put it in a water bath at 60°C, keep i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com