A kind of high-toughness pp composite material replacing abs and its preparation method

A composite material and high toughness technology, applied in the field of high toughness PP composite material replacing ABS and its preparation, can solve problems such as poor toughness, and achieve the effects of making up for poor toughness, saving costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

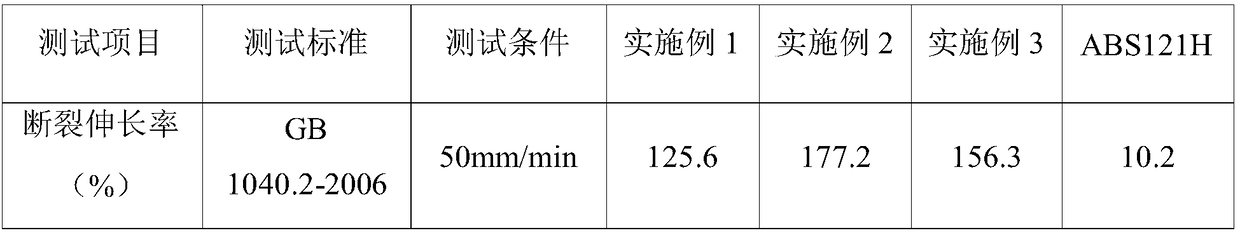

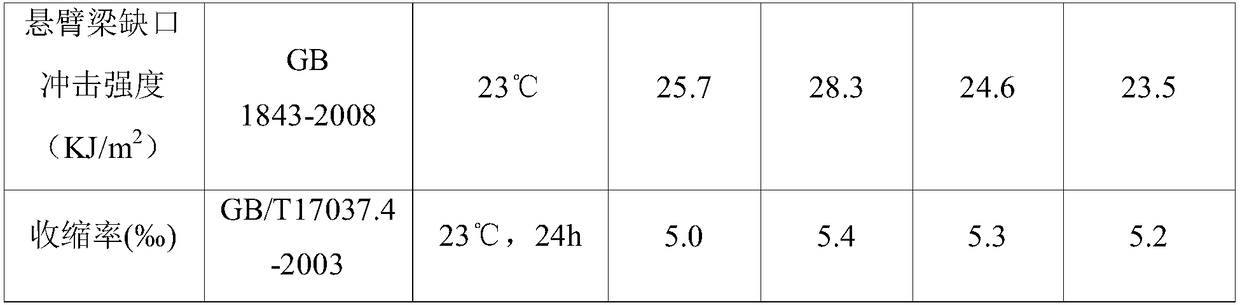

[0023] A kind of high-toughness PP composite material that replaces ABS, and it is prepared by the following method: 22g of low-shrinkage PP resin, 41g of high-impact copolymerized PP resin, 3.7g of toughening agent, talcum powder 32g and auxiliary agent 1.3g (the auxiliary agent Including 0.2g antioxidant 1010, 0.2g antioxidant 168, 0.4g lubricant calcium stearate and 0.5g lubricant PE wax) add in high-speed mixer and stir and mix, add in twin-screw extruder and melt and extrude, extrude The output temperature is controlled at 180-230°C, the screw speed is controlled at 300-500 rpm, and the extruded material is a high-toughness PP composite material that replaces ABS.

Embodiment 2

[0025] A high-toughness PP composite material replacing ABS, which is prepared by the following method: 23.5g of low-shrinkage PP resin, 35.5g of high-impact copolymerized PP resin, 4.7g of toughening agent, 35g of talcum powder and 1.3g of auxiliary agent (the Auxiliaries include 0.2g antioxidant 1010, 0.2g antioxidant 168, 0.4g lubricant calcium stearate and 0.5g lubricant PE wax) add to high-speed mixer and mix, add to twin-screw extruder to melt and extrude , the extrusion temperature is controlled at 180-230°C, the screw speed is controlled at 300-500 rpm, and the extrusion material is a high-toughness PP composite material that replaces ABS.

Embodiment 3

[0027] A kind of high-toughness PP composite material that replaces ABS, and it is prepared by the following method: 25g of low-shrinkage PP resin, 30g of high-impact copolymerized PP resin, 3.7g of toughening agent, talcum powder 40g and auxiliary agent 1.3g (the auxiliary agent Including 0.2g antioxidant 1010, 0.2g antioxidant 168, 0.4g lubricant calcium stearate and 0.5g lubricant PE wax) add in high-speed mixer and stir and mix, add in twin-screw extruder and melt and extrude, extrude The output temperature is controlled at 180-230°C, the screw speed is controlled at 300-500 rpm, and the extruded material is a high-toughness PP composite material that replaces ABS.

[0028] The grade of the low-shrinkage PP resin in Examples 1 to 3 is Basel EC340Q, the grade of the high-impact copolymerized PP resin is BH3820 of SK Korea, the toughening agent is Dow POE8150, and the talcum powder It is Jinhou brand talcum powder, its mesh number is 2000-5000 mesh, and the auxiliary agents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com